| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Tungsten Heavy Alloy |

|---|---|

| Brand Name: | JINXING |

| Model Number: | WNiCu - Tungsten Heavy Alloy Part |

| Certification: | ISO 9001 |

| Place of Origin: | CHINA |

| MOQ: | 10 kg |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, D/P, Western Union |

| Supply Ability: | 2000 kg per month |

| Delivery Time: | 15-20 days |

| Packaging Details: | plywood cases |

| Product Name: | Tungsten Heavy Alloy Part |

| Type: | 90WNiCu |

| Density: | 16.3-18.5 g/cc |

| Purity: | >90% W |

| Tensile Strength: | 750-1400 MPa |

| Elongation: | <9% |

| Standards: | ASTM B777-2010 |

| Applications: | aircraft shocker |

| Company Info. |

| JINXING MATECH CO LTD |

| View Contact Details |

| Product List |

Tungsten Heavy Alloy Part is also called tungsten heavy alloys because tungsten alloys weigh more than twice as much as iron or steel. High specific gravity tungsten alloys are usually refractory metals composed of W-Ni-Fe or W-Ni-Cu or even W-Ni-Cu-Fe two-phase composites. Rare earths and/or other metals such as cobalt, molybdenum and chromium are added to some tungsten alloys. Heavy tungsten alloys have high melting points, are twice as dense as steel and more than 50 percent heavier than lead.

| Chemical Composition | 90%W | 93%W | 95%W | 97%W | ||||||

| State | Sinter | Vacuum | Forge | Sinter | Vacuum | Forge | Sinter | Vacuum | Sinter | Vacuum |

| Density (g/cc) | 16.85-17.25 | 17.15-17.85 | 17.75-18.35 | 18.25- 18.85 | ||||||

| Hardness (HRC) | 32 Max | 30 Max | 40 Min | 33 Max | 31 Max | 40 Min | 34 Max | 32 Max | 35 Max | 33 Max |

| Tensile Strength (Max) | 770 Min | 900 Min | 1400 Max | 770 Min | 910 Min | 1440 Max | 735 Min | 920 Min | 700 Min | 850 Min |

| Yield Strength (Mpa) | 620 Min | 620 Min | 1280 Max | 650 Min | 650 Min | 1340 Max | 650 Min | 650 Min | - | - |

| Elongation (%) | 5 Min | 15 Min | 5 Min | 5 Min | 12 Min | 3 Min | 3 Min | 12 Min | 2 Min | 6 Min |

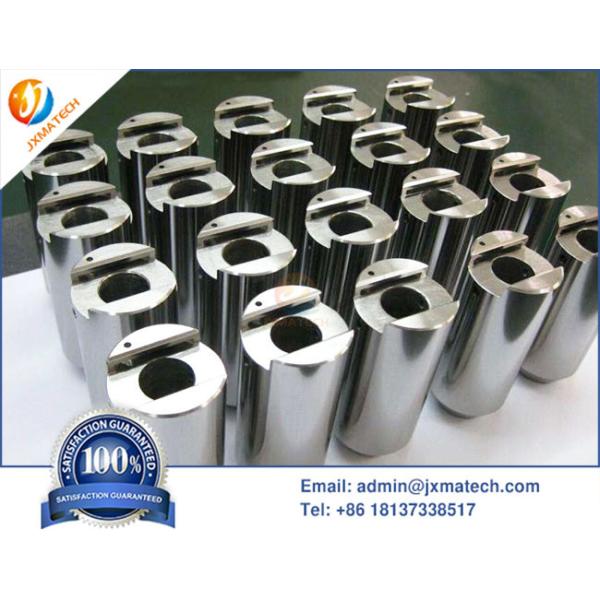

Tungsten Heavy Alloy Part Picture:

|