| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Heat Exchanger Tube |

|---|---|

| Brand Name: | YUHONG |

| Model Number: | ASME SA789 / ASTM A789 |

| Certification: | ISO9001-2008, API 5L, API 5CT |

| Place of Origin: | CHINA |

| MOQ: | 20PC |

| Price: | 1-200000 USD |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 1200 tons/month |

| Delivery Time: | 10-70 days |

| Packaging Details: | Ply-wooden Case /Iron Case/ Bundle With Plastic Cap |

| Standard: | ASME SA789 / ASTM A789 |

| Grade: | UNS S32205 |

| Product: | SMLS Tube |

| Materialrd: | Duplex Steel |

| Certificate: | ISO9001-2008, API 5L, API 5CT |

| Packing Details: | Ply-wooden Case /Iron Case/ Bundle With Plastic Cap |

| Company Info. |

| Yuhong Group Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

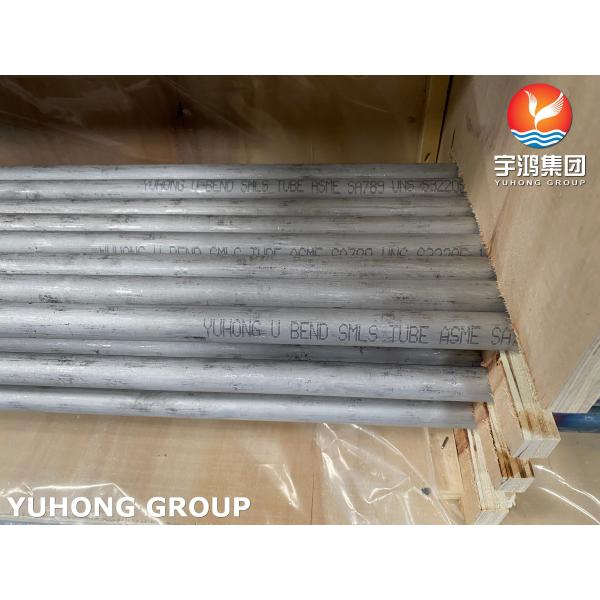

ASME SA789 SMLS UNS S32205 Duplex Steel Bend U Boiler Tubes

YuHong Group can offer SA789/A789 UNS S32205 duplex steel bend U

tubes and we sell these products with highest quality in more than

70 countries.

ASME SA789 / ASTM A789 This specification covers grades of nominal wall thickness,

stainless steel tubing for services requiring general corrosion

resistance, with particular emphasis on resistance to stress

corrosion cracking. These steels are susceptible to embrittlement

if used for prolonged periods at elevated temperatures.

Specifications

| Sizes / Thickness | OD: 0.25"- 6" ; W.T: 0.02" - 0.5" or as required by clients | ||||

| Manufacture | Shall be made by the seamless or welded process with no filler metal added. | ||||

| Heat Treatment | For seamless tubes, as an alternate to final heat treatment in a

continuous furnace or batch-type furnace, immediately following hot

forming while the temperature of the tubes is not less than the

specified minimum solution treatment temperature, tubes may be

individually quenched in water or rapidly cooled by other means. S32205---(1020-1100℃) Quench:rapid cooling in air water | ||||

| Length | As required by clients | ||||

| Surface Condition | All tubes shall be free of excessive mill scale, suitable for

inspection. A slight amount of oxidation will not be considered as

scale. | ||||

| Bending Radius | From 1.5*OD(Outside Diameter) To 1500mm, ≤1.5*OD,necessary To agree precision of geometrics | ||||

| Straight Tubes | max length 35000mm | ||||

U tubes are made by bending straight tubes and bending is done cold on an automatic U-bend. For ensuring tube wall thinning and diameter ovality are controlled, tube bending is accomplished with a mandrel inserted into the tube. Besides, the U-bend of the U-tube is stress relieved under controlled conditions and cycles for extended life.

Duplex stainless steels are called “duplex” because they have a two-phase microstructure consisting of grains of ferritic and austenitic stainless steel.Whilst duplex stainless steel are considered resistant to stress corrosion cracking, they are not as resistant to this form of attack as ferritic stainless steel. Duplex stainless steel are also magnetic, a property that can be used to easily differentiate them from common austenitic grades of stainless.Duplex S32205 stainless steel is used extensively in applications that require good corrosion resistance and strength.It is also used extensively in applications that require good corrosion resistance and strength.

Test Required Bend U tube

Corrosion Test

Chemical Analysis

Reverse-bend and Re. flat tests

Eddy Current Testing

Hydrostatic Testing

Visual Inspection

Mechanical Tests: Tension test, Flattening test, Flaring test, Flange test, Hardness Test and Hydrostatic test

Chemical Composition UNS S32205

| Chemical Composition Max | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| 0.03 | 2 | 0.03 | 0.02 | 1 | 4.5-6.5 | 22-23 | 3-3.5 | 0.14-0.2 |

Mechanical Property

| Steel Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation (%) | Hardness max |

| UNS S32205 | 655min | 485min | 25min | 290HBW 30 HRC |

Applications Industry

Pharmaceutical Equipment

Power Generation

Petrochemicals

Pressure Vessel

Heat Exchangers / Condensers / Boiler

Oil and Gas Processing

Specialty Chemicals

General Engineering

Pulp and Paper Industry

|