| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Steel Tube Making Machine |

|---|---|

| Brand Name: | TengTian |

| Model Number: | HG |

| Certification: | CE |

| Place of Origin: | Hebei |

| MOQ: | 1 Set |

| Price: | $100000 to $1 million |

| Payment Terms: | L/C,T/T |

| Supply Ability: | 50 Sets/Year |

| Delivery Time: | 120 work days |

| Packaging Details: | Export waterproof and Seaworthy packing. |

| Name: | Galvanized Thin Wall Steel Production Line 100 M/Min Steel Tube Making Machine |

| materials: | galvanized |

| Equipment Specification: | customer determined |

| Forming method: | Roller Forming Tube Machine |

| speed: | 100 m/min |

| Warranty: | One year |

| Material: | Low carbon HRC |

| Forming type: | direct forming |

| Work shop: | 100x18 m, H>3m ( crane to ground ) |

| Company Info. |

| Hebei Tengtian Welded Pipe Equipment Manufacturing Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Galvanized Thin Wall Steel Production Line 100 M/Min Steel Tube

Making Machine

I. Common product specifications

| No. | Model | Pipe Size | Thickness | Speed(m/min) | Capacity(KW) | HF(KW) | Area(LxW in Metres) |

| 1 | HG20 | ø8 - ø20 mm | 0.3 - 1.5 mm | 30 - 150 | 210 | 100 | 40*12 |

| 2 | HG32 | ø10 - ø32 mm | 0.4 - 2.0 mm | 30 - 150 | 300 | 150 | 40*12 |

| 3 | HG50 | ø16 - ø50 mm | 0.7 -2.5 mm | 30 - 150 | 410 | 200 | 60*12 |

| 4 | HG60 | ø22 - ø60 mm | 0.9 - 3.0 mm | 30 - 150 | 410 | 200 | 60*12 |

| 5 | HG76 | Ø25 - ø76 mm | 1 - 4 mm | 30 - 120 | 580 | 300 | 80*16 |

| 6 | HG89 | Ø32 - ø89 mm | 1 - 4.5 mm | 30 - 100 | 660 | 300 | 100*16 |

| 7 | HG114 | Ø45 - ø114 mm | 1.5 -5 mm | 30 - 80 | 920 | 400 | 100*16 |

| 8 | HG140 | Ø50 - ø140 mm | 1.5 - 5.5 mm | 30 - 80 | 920 | 400 | 100*16 |

| 9 | HG165 | Ø60 - ø165 mm | 2 - 6 mm | 30 - 60 | 1100 | 500 | 100*16 |

| 10 | HG219 | Ø114 - ø219mm | 3 - 8 mm | 20 - 45 | 1400 | 600 | 150*16 |

| 11 | HG273 | Ø114 - ø273mm | 4 - 12 mm | 15 - 30 | 2100 | 800 | 160*18 |

| 12 | HG325 | Ø165 - ø325 mm | 4 - 14 mm | 10 - 30 | 2500 | 1000 | 200*24 |

| 13 | HG426 | Ø165 - ø426 mm | 4 - 16 mm | 8 - 25 | 2900 | 1200 | 250*24 |

| 14 | HG508 | Ø219 - ø508 mm | 5 - 18 mm | 5 - 18 | 3400 | 1600 | 300*24 |

| 15 | HG610 | Ø355 - ø610 mm | 5 - 18 mm | 5 - 18 | 3700 | 1600 | 300*24 |

| 16 | HG760 | Ø426 - ø760 mm | 5 - 20 mm | 5 - 20 | 4300 | 1800 | 300*24 |

II. Introduction

Galvanized Thin Wall Steel Production Line 100 M/Min Steel Tube

Making Machine has the advantages of adjustable size and high

compressive strength. Widely used in automobiles, railway vehicles,

building doors and Windows transportation, shelves, electrical

cabinets, highway guardrail, building steel structure, containers,

steel formwork and scaffolding, solar bracket shipbuilding,

Bridges, transmission towers, steel sheet piles, cable bridge,

agricultural machinery, furniture, storage, rail, keel steel,

vegetable greenhouses, pipeline support, municipal construction and

other fields.

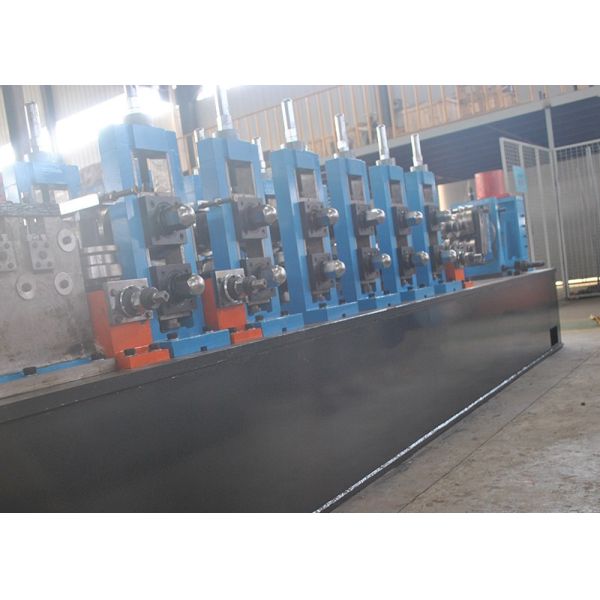

III.Equipment composition of Galvanized Thin Wall Steel Production

Line 100 M/Min Steel Tube Making Machine

Uncoiler :The Single Cone winding is of the structure of double

expansion and cantilever mandrels. It contains two main parts: main

body and the fixed base. The main body is equipped with pneumatic

system to satisfy the needs of expanding, contracting and braking

of the mandrels.

Straightener & leveler :The Straightener is main used to lead the

new coil steel head feed into the leveler after uncoiler unit bring

the coil into the working place. The Leveler is main used to

flatten the head and trail of the strip steel and prepare for the

next step shear and welding, so as to ensure the strip steel

opposed flate and straight in the shear welding.

Automatic shear and welding : Used to cut off the irregular part of

the tape head and tail, and align the tape tail of the previous

coil with the tape head of the next coil, and weld them together.

Forming and sizing part : this forming the steel strip into

round/square/Rec.. The size can be adjusted upon request.

Cold saw : It is used for material cutting of continuous non-stop

cold-formed steel production line. The cutting method is hydraulic

cutting. The high-power servo is equipped with a high-precision

reducer and imported rack and pinion transmission. The accuracy of

cutting (hole distance) is ±5mm. Install imported high-precision

linear guide rail and protective cover

IV. Equipment composition

| No. | Name |

| 1 | Uncoiler |

| 2 | Straightener & leveler |

| 3 | Automatic shear and welding |

| 4 | Accumulator |

| 5 | forming and sizing |

| 6 | cold saw |

| 7 | runout table |

| 8 | Automatic blanking and blocking |

IV. Factory appearance

|