| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Zirconia Ceramic |

|---|---|

| Brand Name: | MH |

| Certification: | ISO9001 RoHS |

| Place of Origin: | CHINA |

| MOQ: | 200 pcs |

| Price: | USD 0.1-6 PCS |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 5000 PCS WEEK |

| Delivery Time: | 15-20DAYS |

| Packaging Details: | CARTON/WOODEN BOX |

| Material: | Zirconia ceramic |

| Color: | White or Black |

| Density: | 5.9g/cm³ |

| Working temperature: | 1400 ℃ |

| OEM,ODM: | Acceptable |

| Sample: | Available |

| Hardness: | 12.3 Gpa |

| Insulation breakdown Intensity: | 15 KT/mm |

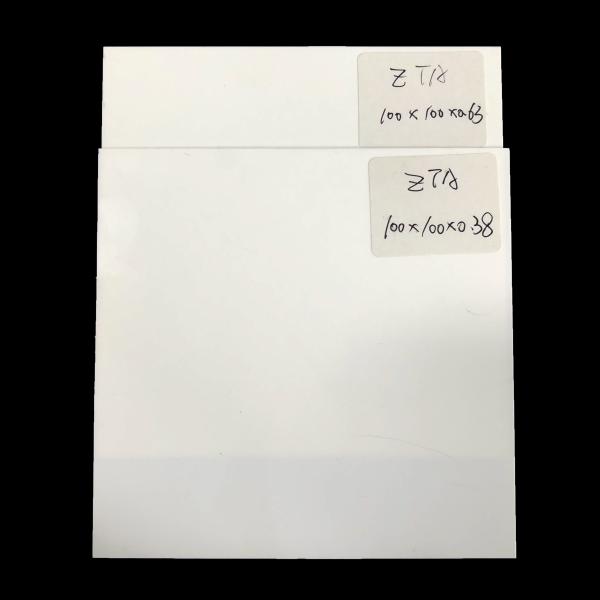

Polished YSZ ZTA Zirconia Ceramic substrate

Zirconia-toughened alumina ceramics, a particle size composition of

the main component of alumina in the preparation of

ceramiccylinder liners for drilling pumps, with an average particle

size of 60-70 wt% in the range of 0.8-1.0 μm and an

averageparticlesize of 30-40 wt% of 1.0 -2.8μm range of two types

of alumina. Add 15vol% of zirconia (containing 2 ~ 3mol% of

yttriumoxide), addappropriate amount of dispersant, mix by ball

milling, spray granulation, isostatic pressing, and fire in the

temperature range of1550 ~ 1620 C, it can be prepared for more than

2000 hours ceramic cylinder liner,and the formingand firing yield

is high, and the raw material and process costs are low. The

performance of zirconia-toughened alumina ceramics is better than

99 aluminaceramics, and the price is much lower than that of

zirconia ceramics.Many occasions where alumina ceramics are

incompetent show a better performance-price ratio than zirconia

ceramics.

Features & Advantages

1. High strength

2. High hardness

3. Wear resistance

4. Non-magnetic

5. Electrical insulation

6. Corrosion resistance in acids and alkalis

7. Modulus of elasticity similar to steel

8. Coefficient of thermal expansion similar to iron

| Properties | Unit | Steatite ceramic | 95% Al2O3 | 99% Al2O3 | Zirconia Ceramic |

| Density | g/cm³ | 2.8 | 3.6 | 3.8 | 5.6 |

| Flexural strength | Mpa | 145 | 300 | 300 | 354 |

| Max Working Temperature | ℃ | 1100 | 1400 | 1600 | 1400 |

| Sintering temperature | ℃ | 1350 | 1700 | 1750 | 1550 |

| Heat resistance | T(℃) | 200 | 220 | 200 | 350 |

| Hardness | Gpa | 5.7 | 7 | 10.7 | 12.3 |

| Elastic modulus | Gpa | 120 | 275 | 320 | 205 |

| Poissons ratio | - | 0.21 | 0.22 | 0.22 | 0.30 |

| Linear expansion coefficient | x 10-6/℃ | 7.9 | 7.1 | 7.8 | 9 |

| Insulation breakdown Intensity | KT/mm | 10 | 16 | 18 | 15 |

| Thermal conductivity | w/(m.k) | 2.5 | 20 | 25 | 2.5 |

| Specific Heat | *10-3J/(kg*K) | 0.75 | 0.78 | 0.78 | 0.4 |

|