| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Aluminum Rod Bar |

|---|---|

| Brand Name: | JBHD |

| Model Number: | 1100 2024 3003 5052 5751 6061 6063 7075 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 ton |

| Price: | Negotiation |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 10000 Ton |

| Delivery Time: | 7-15 working days |

| Packaging Details: | Standard seaworthy package |

| Material: | 1100 2024 3003 5052 5751 6061 6063 7075 |

| Edge: | Mill Edge Slit Edge |

| Technique: | EXTRUDED |

| Temper: | H14 |

| Surface: | Mill Finish Polished |

| Price term: | EXW FOB CIF CFR |

What is 1100 aluminum used for?

Aluminum 1100 can be shaped into many different products, including chemical equipment, railroad tank cars, fin stock, dials, name plates, cooking utensils, rivets, reflectors and sheet metal. The plumbing and lighting industries also use aluminum 1100, as do a wide variety of other industries.

What is the difference between Al 1100 and 6061?

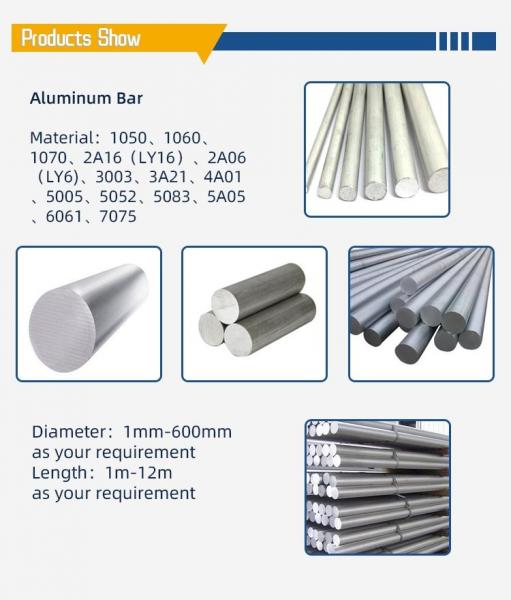

| Products Name | aluminum bars |

| Material | Aluminum |

| Other Material | 1060, 1050, 1070, 1100, 3003, 3004, 5052, 5652, 5154, 5254, 5454, 5083, 5086, 5056, 5456, 2024, 2014, 6061, 6063 ,etc |

| Standard | ASTM, SUS, DIN etc |

| Surface | Bright, polished, hair line, brush, embossed, etc |

| Payment Term | L/C , D/A , D/P , T/T , West Union , Money Gram , other |

| Price Term | FOB, CIF, CFR , CNF etc |

| Package | Export standard package:bundled wooden box or be required; The inner size of container is below: (1)20 foot GP:5.8m(length)x2.13m(width)x2.18m(high)about24-26 CBM (2)40 foot GP:11.8m(length)x2.13m(width)x2.72m(high)about68 CBM |

| Delievery Time | 5-15days |

| Loading Port | china |

| Supply Ability | 3000 tons per yaer |

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | OTHERS | OTHERS | Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | — | 0.05 | 0.03 | 0.03 | — | 99.5 |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | — | 0.04 | 0.03 | 0.03 | — | 99.7 |

| 1100 | 0.95 Si + Fe | 0.05-0.20 | 0.05 | — | — | 0.1 | — | 0.05 | 0.15 | 99 | |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.30-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Rem. |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | — | — | 0.1 | — | 0.05 | 0.15 | Rem. |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | — | 0.25 | — | 0.05 | 0.15 | Rem. |

| 3005 | 0.6 | 0.7 | 0.3 | 1.0-1.5 | 0.20-0.6 | 0.1 | 0.25 | 0.1 | 0.05 | 0.15 | Rem. |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.50-1.1 | 0.1 | 0.25 | — | 0.05 | 0.15 | Rem. |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | — | 0.05 | 0.15 | Rem. |

| 5252 | 0.08 | 0.1 | 0.1 | 0.1 | 2.2-2.8 | — | 0.05 | — | 0.03 | 0.1 | Rem. |

| 6061 | 0.40-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Rem. |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Rem. |

| Alloy | Temper | Tensile Strength | Yield Strength | Elongation (%) | Tensile Strength | Yield Strength | |

| (ksi) | (ksi) | 0.01-0.05 in | 0.051-0.125 in | (MPa) | (MPa) | ||

| 1100 | H12 | 16 | 15 | 4 | 12 | 110.3 | 103.4 |

| H14 | 18 | 17 | 3 | 10 | 124.1 | 117.2 | |

| 3003 | H12 | 19 | 18 | 9 | 11 | 131 | 124.1 |

| H14 | 22 | 21 | 3 | 7 | 151.7 | 144.8 | |

| 3004 | H32 | 31 | 25 | 6 | 15 | 213.7 | 172.4 |

| H34 | 35 | 29 | 5 | 10 | 241.3 | 199.9 | |

| 3005 | H12 | 26 | 24 | 5 | 13 | 179.3 | 165.5 |

| H14 | 29 | 28 | 4 | 9 | 199.9 | 193.1 | |

| 5005 | H12 | 20 | 19 | 5 | 9 | 137.9 | 131 |

| H14 | 23 | 22 | 4 | 7 | 158.6 | 151.7 | |

| 5052 | H32 | 33 | 28 | 7 | 10 | 227.5 | 193.1 |

| H34 | 38 | 31 | 6 | 8 | 262 | 213.7 | |

| 5056 | O | 42 | 22 | 23 | 24 | 289.6 | 151.7 |

| H38 | 60 | 50 | 6 | 13 | 413.7 | 344.7 | |

| 6061 | T4 | 35 | 21 | 22 | 24 | 241.3 | 144.8 |

| T6 | 45 | 40 | 12 | 17 | 310.3 | 275.8 | |

| 7075 | O | 33 | 15 | 16 | 18 | 227.5 | 103.4 |

| T6 | 83 | 73 | 11 | 12 | 572.3 | 503. | |

Company Introduction

Certification

|