| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Street Light Poles |

|---|---|

| Brand Name: | milky way |

| Model Number: | 69KV |

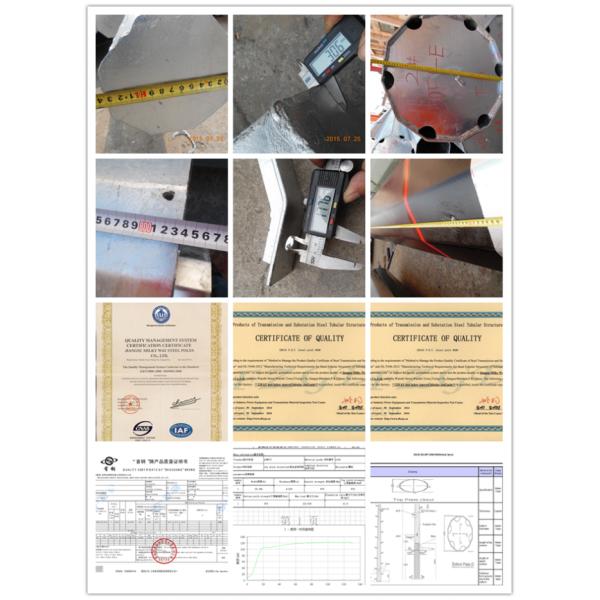

| Certification: | ISO9001:2015 |

| Place of Origin: | JIANGSU,CHINA |

| MOQ: | ONE CONTAINER |

| Price: | USD 130-180POLE |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 1000POLES/MOUTH |

| Delivery Time: | ALWAYS 20DAYS |

| Packaging Details: | The normal package is container(Size: L*W*H). Our poles as normal cover by Mat or straw bale at the top and bottom and wood between the poles to avoide the damage on the galvanization of the pole , anyway also can following by client required , The lo |

| MATERIAL: | S355JR |

| APPLICATION: | electricity distribution |

| THICKNESS: | 2.5-10MM |

| SHAPE: | POLYGON |

| GALVANIZATION: | ASTM A123,average coationg not less than 85um |

| WELDING: | AWS D1.1,penetration 100% |

| LIFETIME: | 50 YEARS |

| WIND SPEED: | 160KM/H |

| ULTIMATE TENSILE STRENGTH: | 490-620MPA |

| Company Info. |

| Jiangsu milky way steel poles co.,ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

pecification:

1. Quality Q345/Q235 steel plate

2. advanced equipent

3. high level technical personnel

4. hot dip galvanization

Drawings:

| Type | Street Lamp pole, lamp post . Lamp column |

| Shape | Conoid ,Multi-pyramidal,Columniform,polygonal or conical |

| Material | Usually Q345B/A572,minimum yield strength>=345n/mm2 Q235B/A36,minimum yield strength>=235n/mm2 As well as Hot rolled coil from Q460 ,ASTM573 GR65, GR50 ,SS400, SS490ST52 |

| Torlance of dimenstion | -0.02 |

| Design Load in Kg | 300~ 1000 Kg appliced to 50cm from the to pole |

| Surface treatment | Hot dip galvanized Following ASTM A 123, color polyester power or any other standard by client required. |

| Standard | Octagonal tapered column Certified by SIRIM QAS INTERNATIONAL. Approved by JABATAN KERJA RAYA MALAYSIA. Conforms to Standard: Pole design : BS EN 40 Material : BS EN 10025 S275 / JIS G3101 SS400 Welding : BS 5135 Galvanizing : BS 729 / ISO 1461 ASTM A 123 |

| Length of per section | Within 14m once forming without slip joint. |

| Suit for | Highway Roadway Residential subdivisions Commercial development |

| Option | Height from 6m to 12m Flange mounted or planted type Variable arm length from 0.125m to 3.0m with single or double arm type Variable spigot size from 35mm to 60mm. |

| Production Process | Raw material test → Cutting →Molding or bending →Welidng (longitudinal )→Dimension verify →Flange welding →Hole drilling →Calibration →Deburr→Galvanization or powder coating ,painting →Recalibration →Thread →Packages |

|