| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Stainless Steel Round Bar |

|---|---|

| Brand Name: | Shuangti |

| Model Number: | Sus304 |

| Certification: | ISO,BV,SGS |

| Place of Origin: | Wuxi,Jiangsu Province,China |

| MOQ: | MOQ :1 kg |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 5000 tons per day |

| Delivery Time: | 5-8 working days |

| Packaging Details: | Gel pressed board pallet or cabinet |

| Grade: | 300 Series,400 Series,200 Series,Hastelloy,200 Series/300 Series/400 Series/500 Series/600 Series/2B |

| Application: | Construction,Industry,Machine Building,Architecture,chemical |

| Standard: | AISI,ASTM,JIS,DIN,GB |

| Surface: | 2B,BA,NO.1,HL,BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Edge: | Mill Edge Slit Edge,Slit |

| Color: | Natural Color,White Bright |

| OD: | 16~180mm |

| Material: | 201, 202, 301, 302, 304, 304L, 310S, 316, 316L, 321, 430, 430A, 309S, 2205, 2507, 2520, 430 , 410, 440, 904Lect, Or Customized |

| Type: | Round,Flat,Alloy Steel Bar,Square |

Product description

Stainless steel is an alloy of Iron with a minimum of 10.5%

Chromium. Chromium produces a thin layer of oxide on the surface of

the steel known as the passive layer. This prevents any further

corrosion of the surface. Increasing the amount of Chromium gives

an increased resistance to corrosion.

Stainless steel also contains varying amounts of Carbon, Silicon

and Manganese. Other elements such as Nickel and Molybdenum may be

added to impart other useful properties such as enhanced form

ability and increased corrosion resistance.

| Product Name | Stainless Steel Bar / Rod |

| Shape | Round bar,Angle bar,Channel bar,Square bar,Flat bar,I/H bar,Hexagonal bar and profiles |

Outer Diameter (OD) | Peeling Bar: 16~180mm Cold Drawn Bar: 4.76~120mm (All sizes can be customized) Forged Bar: 180~400mm |

| Technique | Hot Rolled,Cold Rolled,Cold Drawn,Forged |

| Material | 201, 202, 301, 302, 304, 304L, 310S, 316, 316L, 321, 430, 430A, 309S, 2205, 2507, 2520, 430 , 410, 440, 904Lect, Or Customized |

| Standard | ASTM, JIS, GB, AISI, DIN, BS,EN |

| Certifications | ISO 9001 BV SGS |

| Packing | Industry standard packaging or according to client's requirement |

| Payment terms | 30%T/T in advance, the balance against the B/L copy |

| Delivery time | Fast delievery in 7 days,up to order quantity |

Stainless Steel Surface Treatments

1D—The surface has discontinuous particles, which is also called

matte. Processing technology: hot rolling + annealing shot peening

pickling + cold rolling + annealing pickling.

2D—Slightly shiny silver-white. Processing technology: hot rolling

+ annealing shot peening pickling + cold rolling + annealing

pickling.

2B—Silver white and better gloss and flatness than 2D surface.

Processing technology: hot rolling + annealing shot peening

pickling + cold rolling + annealing pickling + quenching and

tempering rolling.

BA—The surface gloss is excellent and has a high reflectivity, just

like the mirror surface. Processing technology: hot rolling +

annealing shot peening pickling + cold rolling + annealing pickling

+ surface polishing + quenched and tempered rolling.

No.3—has better gloss and rough surface. Processing technology:

Polishing and tempering rolling of 2D products or 2B with 100 ~ 120

abrasive materials.

No.4—has better gloss and fine lines on the surface. Processing

technology: Polishing and tempering rolling of 2D products or 2B

with 150 ~ 180 abrasive materials.

HL—Silver gray with hair streaks. Processing technology: Polish the

2D product or 2B product with a suitable size of abrasive material

to make the surface appear continuous grain.

MIRROR Machining —is in a mirror state. Processing technology: 2D

or 2B products are ground and polished to a mirror effect with a

suitable abrasive material.

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building construction |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

Corresponding photo of stainless steel surface treatment

Stainless Steel Composition Contents Proportion Table

| 200 series | |||||||||||||

| Grade | chemical composition (%) | mechanic performances | |||||||||||

| C | Si | Mn | P | S | Ni | Cr | N | Cu | Y.S(N/mm2) | T.S(N/mm2) | Elog(%) | HRB | |

| 201(1%nickel) | ≤0.15 | ≤1.00 | 8∽11 | ≤0.060 | ≤0.030 | 0.9∽1.5 | 15∽17 | ≤0.25 | 1.5∽2 | ≥310 | ≥655 | ≥35 | ≤105 |

| 202(4%nickel) | ≤0.15 | ≤1.00 | 6∽9 | ≤0.060 | ≤0.030 | 3.5∽5 | 15∽17 | ≤0.25 | 1.5∽2 | ≥260 | ≥620 | ≥40 | ≤100 |

| The specification of type 201&202 in conformity with Mill Standard | |||||||||||||

| 300 series | |||||||||||||

| Grade | chemical composition (%) | mechanic performances | |||||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Y.S(N/mm2) | T.S(N/mm2) | Elog(%) | HRB | ||

| 304 | ≤0.08 | ≤0.75 | ≤2 | ≤0.045 | ≤0.030 | 8∽10 | 18∽20 | ≥205 | ≥520 | ≥40 | ≤90 | ||

| 301 | ≤0.15 | ≤1.00 | ≤2 | ≤0.045 | ≤0.030 | 6∽8 | 16∽18 | ≥205 | ≥515 | ≥40 | ≤95 | ||

| 316 | ≤0.08 | ≤1.00 | ≤2 | ≤0.045 | ≤0.030 | 10∽14 | 16∽18 | 2∽3 | ≥205 | ≥515 | ≥40 | ≤90 | |

| 316L | ≤0.03 | ≤1.00 | ≤2 | ≤0.045 | ≤0.030 | 12∽15 | 16∽18 | 2∽3 | ≥170 | ≥480 | ≥40 | ≤95 | |

| The specification of type 301,302,304,304L,309S,310S,316,316L,321,347 in conformity with ASTM & JIS criteria | |||||||||||||

| 400 series | |||||||||||||

| Grade | chemical composition (%) | mechanic performances | |||||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Y.S(N/mm2) | T.S(N/mm2) | Elog(%) | HRB | ||

| 430 | ≤0.12 | ≤1.00 | ≤1 | ≤0.040 | ≤0.030 | 16∽18 | ≥450 | ≥205 | ≥22 | ≤88 | |||

| The specification of type 430,410,420J1.420J2 in conformity with ASTM & JIS criteria | |||||||||||||

| 630 series | |||||||||||||

| Grade | chemical composition (%) | mechanic performances | |||||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Nb | Y.S(N/mm2) | T.S(N/mm2) | Elog(%) | HRB | |

| 630 | ≤0.07 | ≤1.00 | ≤1.00 | ≤0.035 | ≤0.030 | 6.50∽7.50 | 15.50∽17.50 | 0.15∽0.45 | ≥450 | ≥205 | ≥22 | ≤88 | |

| The specification of type 630 in conformity with ASTM & JIS standard | |||||||||||||

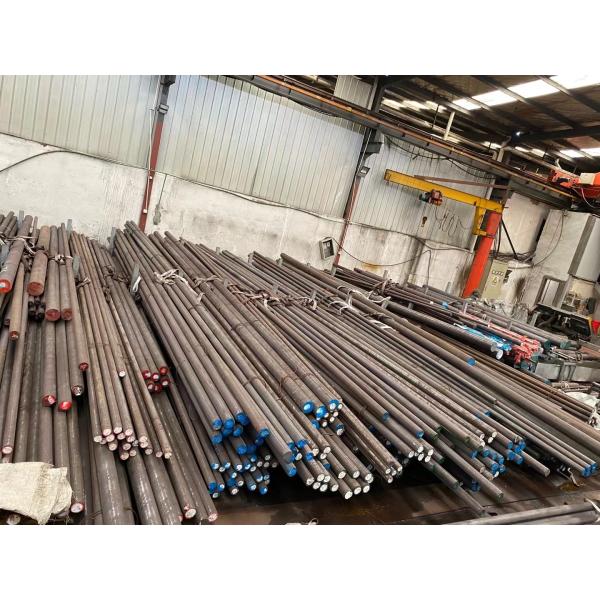

product photos

|