| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Steel Flange |

|---|---|

| Brand Name: | YUHONG |

| Model Number: | ASTM A105, ASME SA105 |

| Certification: | ABS, GL, DNV, NK, PED, AD2000, GOST9941-81, CCS, ISO 9001-2015 |

| Place of Origin: | China |

| MOQ: | 1 Piece |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C |

| Supply Ability: | According To Clients' Request |

| Delivery Time: | 5 - 60 Work Days |

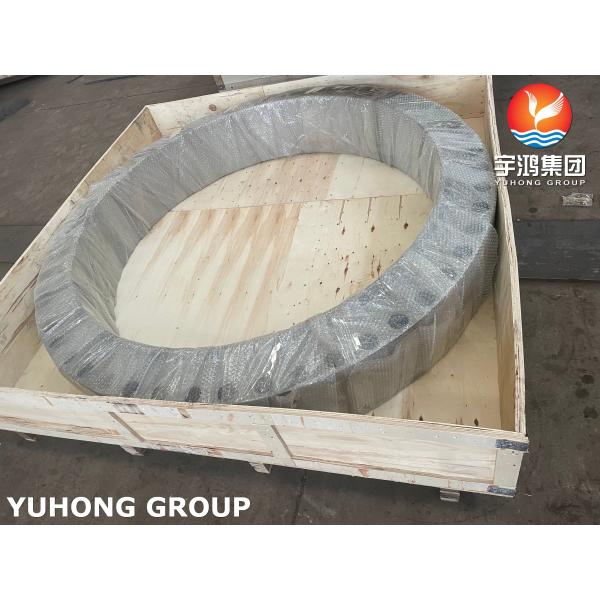

| Packaging Details: | Ply-wooden Case / Pallet |

| Standard: | ASTM A105, ASME SA105 |

| Product Name: | Carbon Steel Body Flange |

| Size: | Customized Size, 1/8"-4 8" |

| Schedule: | SCH5S - SCHXXS |

| Technics: | Forged |

| Applications: | Chemical,Food Processing,Oil And Gas, Petrochemical,Etc. |

| Company Info. |

| Yuhong Group Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Forged Flange, ASME SA105 Carbon Steel Body Flange For Shell And Tube Heat Exchangers

ASTM A105 carbon steel body flange is a reliable and versatile component which is widely used in various industries. Its composition of carbon and iron and its exceptional properties such as high tensile strength and corrosion resistance make it an ideal choice for demanding applications.

ASTM A105 Carbon Steel Flange is widely used in the construction of various types of pipe systems, particularly in oil and gas, petrochemical, and power generation industries. A105 Carbon Steel Flange has high strength and resistance to thermal creep deformation, making it ideal for being used in high-temperature applications. Its good ductility and toughness make it ideal for being used in pressure equipments which require a high level of structural integrity.

Specifications:

| Specifications | ASTM A105, ASME SA105 |

| Size | 1/2” to 48” |

| Pressure Ratings | Class 400 LB, 150 LB, 1500 LB, 300 LB, 900 LB, 2500 LB, 600 LB |

| Face Type | Raised Face, Flate Face, Ring Type Joint |

| Surface Treatment | Cold and Hot Dip Galvanized, Yellow Transparent, Oil Black Paint, Anti-rust Paint, Zinc Plated. |

Chemical Composition:

| Element | Composition, % |

| C | ≤ 0.35 |

| Mn | 0.60-1.05 |

| P | ≤ 0.035 |

| S | ≤ 0.040 |

| Si | 0.10-0.35 |

| Cu | ≤ 0.40 |

| Ni | ≤ 0.40 |

| Cr | ≤ 0.30 |

| Mo | ≤ 0.12 |

| V | ≤ 0.08 |

Mechanical Properties:

| Tensile Strength min. | Yield Strength min. | Elongation min. | Reduction of Area, min. | Hardness | ||

| MPa | ksi | MPa | ksi | % | % | HBW |

| 485 | 70 | 250 | 36 | 22 | 30 | 137-187 |

Applications:

Heat Exchangers

Chemical Industry

Power Plant

Fabrication Industry

Food Processing Industry

Oil and Gas Pipeline

Paper & Pulp Industry

Water Supply Systems

|