| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Heat Exchanger Tube |

|---|---|

| Brand Name: | YUHONG |

| Model Number: | ASTM B444 |

| Certification: | ISO9001-2015, API 5L, API 5CT |

| Place of Origin: | CHINA |

| MOQ: | 1TON |

| Price: | 1-130000 USD |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 1000tons/month |

| Delivery Time: | 45 -60 days |

| Packaging Details: | Ply-wooden case |

| Materialrd: | Nickel Alloy Steel |

| Product: | Seamless Tube |

| Standard / Material: | ASTM B444 / NO6625 |

| Certificate: | ISO9001-2015, API 5L, API 5CT |

| Delivery Status: | Annealed, Normalized, Normalized+Tempered,etc. |

| Related Testes: | chemical composition test, mechanical properties test(tensie, yield, elongation), process properties test(latting,faring.bending, hardness, impact, etc.), appearance and size test, non-destructive inspection test, hydrostastic test. |

| Packing Details: | Ply-wooden case |

| Use: | Heat Exchanger / Boiler / Furnase, etc |

| Company Info. |

| Yuhong Group Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

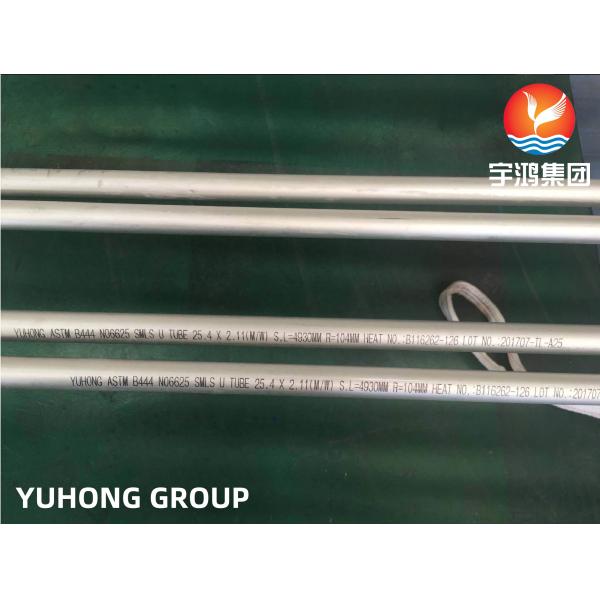

ASTM B444 UNS NO6625 Nickel Alloy Steel Seamless U Bend Tubes for Calderas

YuHong Group as one of the leading suppliers in China to supply

B444 NO6625 seamless nickel alloy steel u bend tubes.And we have

many experiences in exporting.

Each U bend tube of our range is rigorously quality checked by our

team of professionals on every produce of production to provide

customers with defect-free quality products. These U-shaped bends

can be custom designed in various diameters according to customer

requirements and drawings.

ASTM B444 This specification covers nickel-chromiummolybdenum-columbium alloys (UNS N06625 and UNS N06852) and nickel-chromium-molybdenum-silicon alloy (UNS N06219) in the form of cold-worked seamless pipe and tube.

Inconel 625 has excellent strength at temperatures up to 816C. At higher temperatures , its strength is generally lower than that of other solid solution strengthened alloys.

Inconel 625 has good oxidation resistance at temperatures up to 980℃C and showsgood resistance to aqueous corrosion, but is relatively moderate compared to other more capable corrosion resistant alloys.

UNS N06625 products are furnished in two grades of different heat-treated conditions:

Grade 1 (annealed)—Material is normally employed in service temperatures up to 1100°F (593°C).

Grade 2 (solution annealed)—Material is normally employed in service temperatures above 1100°F (593°C) when resistance to creep and rupture is required.

Application: Boilers, heat exchangers, super heaters, condensers, furnase, chemical process industry, sea water application, etc,

Chemical Composition

| C | Mn | P | SI | S | Cr | Cb+Ta |

| 0.1max | 0.5max | 0.015max | 0.5max | 0.015max | 20-23 | 3.15-4.15 |

| Co | Mo | Fe | Al | Ti | Ni | / |

| 1max | 8-10 | 5max | 0.4max | 0.4max | 58min | / |

Mechanical Property

| Grade | Tensile Strength(Mpa) min | Yield Strength (Mpa) min | Elongation (%) |

| Gr 1 (annealed)D | 827 | 414 | 30 min |

| Gr 2(solution annealed)E | 690 | 276 | 30 min |

D: Annealed at 1600°F (871°C) minimum.

E: Solution annealed at 2000°F (1093°C) minimum, with or without subsequent stabilization anneal at 1800°F (982°C) minimum to increase resistance to sensitization.

Welcome to your inquiry to YUHONG Group!

|