| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Heat Exchanger Tube |

|---|---|

| Brand Name: | YUHONG |

| Model Number: | ASME SB407 |

| Certification: | ABS Approved |

| Place of Origin: | CHINA |

| MOQ: | 500kgs |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 800 Tons/ Month |

| Delivery Time: | 7DAYS |

| Packaging Details: | Ply-wooden Case /Iron Case/ Bundle with plastic Cap etc. |

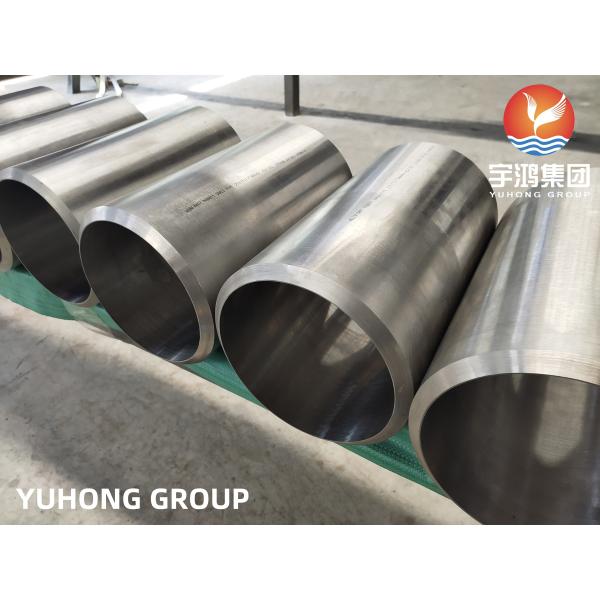

| Product Name: | Nickel Iron Chromium Alloy Seamless Tube |

| OD: | 3.00 - 219.10 mm |

| Thickness: | 0.40 - 12.70 mm |

| Material Grade: | UNS N08811, Incoloy 800HT, DIN1.4958 |

| End: | Beveled Ends(BE) |

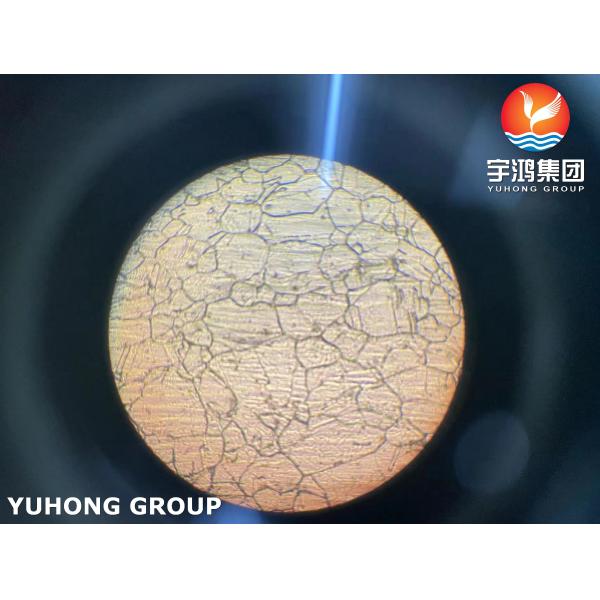

| Test Report: | Chemical Analysis, Mechanical Properties, Grain Size, Hydrostatic Test |

| Company Info. |

| Yuhong Group Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

ASME SB407 N08811 Seamless Tube for Petrochemical Heat Exchangers ABS Certified

The mechanical properties of Incoloy 800/800HT alloys are combined with their resistance to corrosion at elevated temperatures, making them extremely suitable for use in various high-temperature and long-term operations.

These alloys are also largely used in various corrosive media. The chemical composition limits of Incoloy 800H and 800HT alloys are within the limits of INCOLOY 800. Alloy 800 has high mechanical strength at high temperatures. It is suitable for use at temperatures up to 1500oF.

The important difference between Incoloy alloy series depends on the difference in their mechanical properties.

The difference in mechanical properties is due to the difference in their chemical composition and different annealing temperatures. In general, Incoloy 800 alloy has higher mechanical properties at room temperatures and minimal to high temperatures. On the other hand, Incoloy 800H and 800HT alloys offer high resistance to creep and stress cracking at higher temperatures.

ASME SB407 N08811 Nickel Iron Chromium Alloy Seamless Tube Chemical Composition

| Alloy | % | Ni | Cr | Fe | C | Mn | Si | Cu | S | Al | Ti |

| UNS N08800 | Min. | 30 | 19 | 0.15 | 0.15 | ||||||

| – | Max. | 35 | 23 | balance | 0.1 | 1.5 | 1 | 0.75 | 0.015 | 0.6 | 0.6 |

| UNS N08810 | Min. | 30 | 19 | 0.05 | 0.15 | 0.15 | |||||

| – | Max. | 35 | 23 | balance | 0.1 | 1.5 | 1 | 0.75 | 0.015 | 0.6 | 0.6 |

| UNS N08811 | Min. | 30 | 19 | 0.06 | 0.15 | 0.15 | |||||

| – | Max. | 35 | 23 | balance | 0.1 | 1.5 | 1 | 0.75 | 0.015 | 0.6 | 0.6 |

ASME SB407 N08811 Nickel Iron Chromium Alloy Seamless Tube Specification

Rod, Bar, Wire, Forgings, and Forging Stock

Plate, Sheet, and Strip

Pipe and Tubes

ASME SB407 N08811 Nickel Iron Chromium Alloy Seamless Tube Mechanical Properties

Alloy | Density | Tensile Stress | Yield Stress (0.2%Offset) | Elongation |

| Inconel 800HT Tube | 7.94 g/cm3 | Psi - 65,000 , MPa - 450 | Psi - 25,000 , MPa - | 30 % |

ASME SB407 N08811 Nickel Iron Chromium Alloy Seamless Tube Equivalent

| NICKEL ALLOY | DIN | UNS | JIS | BS | GOST | AFNOR | EN | OR |

| Incoloy 800HT | 1.4958 | N08811 | NCF 800HT | NA 15(HT) | ЭИ670 | - | X8NiCrAlTi32-21 | XH32T |

What forms of Incoloy® 800H/HT do we offer?

|