| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Truck Air Springs |

|---|---|

| Brand Name: | GUOMAT |

| Model Number: | 1T8748 |

| Certification: | ISO/TS16949:2009 |

| Place of Origin: | GuangDong, China |

| MOQ: | 6pcs |

| Price: | $89.9-99.9/pc |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 1000pcs/week |

| Delivery Time: | 2-8 work days |

| Packaging Details: | strong carton box or as customers need |

| Application: | Truck/Trailer/Heavy Truck |

| Material: | Metal and Rubber |

| Warranty: | 1 Year |

| Quality: | 100% Tested |

| Operate: | Inflatable |

| Price condition: | FOB China |

| Sample: | Available |

| Suspension System: | Air Spring Suspension |

| Company Info. |

| GUANGZHOU GUOMAT AIR SPRING CO. , LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

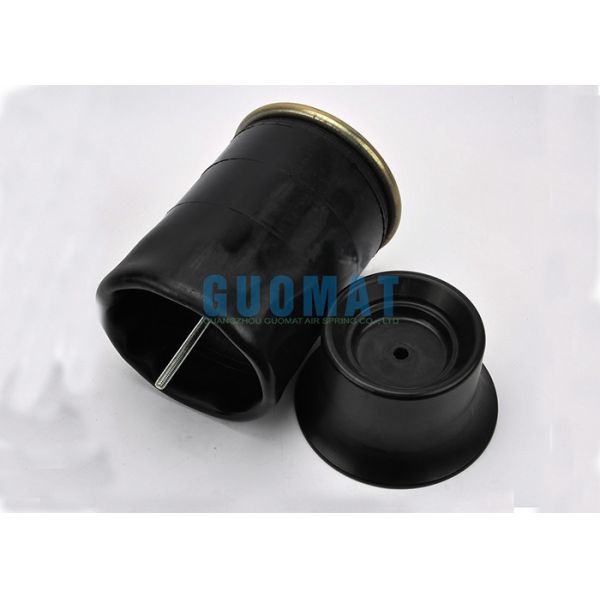

W01-358-8748 Firestone Rolling Lobe Air Spring Trailer Suspension

Air Bag Replacement

Product Details

GUOMAT Number | 1T8748 |

Operating Temperature | -40°C bis +70°C |

Failure Testing | ≥3 millions |

Material | Rubber |

Type of Goods | Air Spring/Air bags/Air Balloons |

Sample | Available |

Package | Standard packing or customized |

Original Equipment Number / OE Number

Firestone Bellows Number: 1T17B-11

Firestone Airide Air Spring: W01-358-8748 / WO1-358-8748

Firestone Airide Air Spring: W01 358 8748 / WO1 358 8748

Firestone Airide Air Spring: W013588748 / WO13588748

Contitech OEM Number: 101021P570

Goodyear OEM Number: 1R13-152 / 1R 13-152 / 1R13 152

Goodyear Bllows Number: 566263071 / 566-26-3-071 / 566 26 3 071

Goodyear Piston Number: 566-20-7-235 / 566 20 7 235 / 566207235

NEWAY: 90557167

NEWAY: 90557288

TRIANGLE: 8570/6394

SAF HOLLAND: AR 250(14,15)

SAF HOLLAND: RL 250(14,15)

UPC: 767555022306

MPN: W013588748

GUOMAT rubber air spring is a curved capsule made of rubber and mesh wire. The two ends of the capsule need to be connected with two steel plates and have a compressed air chamber. The rubber and network cables themselves do not provide load-carrying capacity, but are provided by the compressed air filled into the capsule. Rubber air springs are also called rubber air stroke regulators and rubber air vibration isolators according to their performance and characteristics.

Air spring designs can use compressed air or ammonia gas. Air

springs can also be filled with water or water-glycol solution. If

filled with water, rust inhibitor must be added to protect the end

cover. The air spring will be filled with liquid in two cases:

1. Reduce the internal air volume (thereby increasing the natural

frequency of the air spring)

2. Use incompressible media. One of the reasons for this is precise

positioning.

Petroleum-based fluids (which most hydraulic oils fall into) are

not recommended. Lightly lubricated air is not harmful to air bags

Our rule of thumb is:

1. The maximum pressure of the two-line mesh airbag is 0.7MP.

We recommend a minimum safety factor of three times between maximum

internal pressure and burst pressure. For example, if the required

pressure is 0.7MP, the burst pressure should be greater than or

equal to 2.1MP. For curved bladder air springs, our burst air

pressure requirement reaches 3MP. For the application of GUOMAT air

spring shock absorbers, the maximum pressure of the two-wire mesh

air spring is best limited to within 0.7MP, and the maximum

pressure of the high-strength air spring (special requirements for

thickened four-layer cords is best limited to 1.2MP)

Standard air bags. Our company's standard industrial air spring is a rubber product made of natural rubber as the main body and vulcanized with various rubber compound formulas. The working temperature should be limited to the range of -40℃-70℃.

According to the experimental test fatigue life standard, the GUOMAT bladder rubber air spring has not been damaged after vibrating 3 million times under the conditions of 0.5MP gas, amplitude 40mm, and frequency 2.7Hz (160 times/min).

A protective cover should be used to protect the bladder from exposure to hot metal, sand, petroleum-based liquids, acids, etc. The airbag can withstand a certain amount of pollution in most cases (liquid pollution such as acid, weak acid and alkali environments are allowed to be used, but it will affect the service life of the airbag to a certain extent)

Best stored in a dark, dry room temperature environment

|