| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Copper Round Bar |

|---|---|

| Brand Name: | DELTA |

| Model Number: | C10200 |

| Certification: | ISO |

| Place of Origin: | China |

| MOQ: | 200 kgs |

| Price: | 8 - 9 USD/Kg |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Supply Ability: | 15 Tons per month |

| Delivery Time: | 5 - 10 days |

| Packaging Details: | wooden pallets |

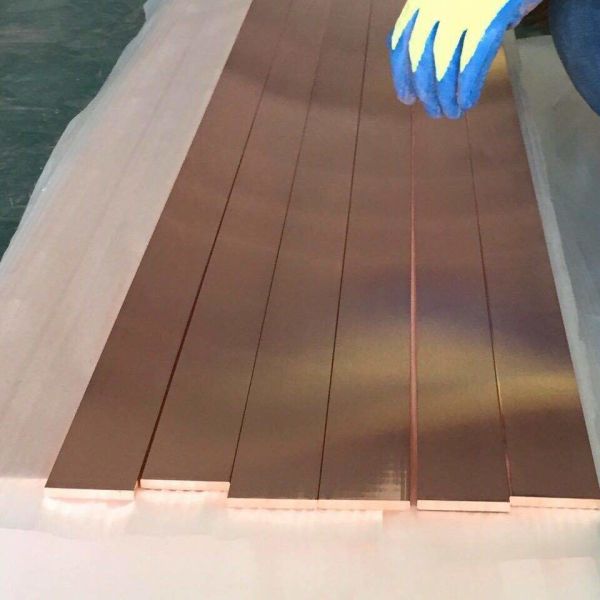

| Products: | Copper flta bar |

| Grade: | C10200 |

| Standard: | ASTM GB EN DIN JIS |

| Thickness: | 0.5 - 60.0mm |

| Width: | within 1000mm |

| Length: | 6m or custom as request |

| Certificate: | EN 10204-3.1 |

| Other products: | Pipe , round bar, strips |

| Company Info. |

| JIANGSU MITTEL STEEL INDUSTRIAL LIMITED |

| Verified Supplier |

| View Contact Details |

| Product List |

OF-CU C10200 / 102 / 2.0040 ASTM DIN Standard Copper Plate Sheet EN 10204-3.1

Product name | Copper Plate & Sheet |

| Copper and copper alloy grade | C11000,C10100,C10200 H59, H60, H62, H65, H68, H70, H80, H85, H90, H96, C2100,

C2200,C2300, C2400, C2600, C2680, C2720, C2800, C3560, C3601,

C3713, C3771, C3561 , CuZn30, CuZn32, CuZn35, CuZn37, CuZn40 ,TU1,

T2, TP2, H96, H90, H85, H80, H70, H65, H63, H62, H59, HPb63-3,

HPb66-0.5, HPb62-2, HPb62-3, HPb59-3, HSn70-1, HSn62-1,QSn8-0.3,

QSn4-4-4, QAl9-4, QSB-1 etc. |

| Width | Within 1500mm Custom Cutting any width as request |

| Thickness | 0.5 - 200.0mm |

Length | 1m 2m 3m 6m or custom cutting any length as request |

| Standard | ASTM EN DIN JIS GB |

| Other products | Plate, Sheet, Coil , Pipe, Round Bar, Square Bar, Flat Bar, Hexagonal Bar.etc |

C102 is a type of pure copper designed for use in electrical engineering and electronic product applications. Copper C102 has excellent electrical and thermal conductivity, making it an ideal material for electronic components. Its great resistance to corrosion makes it an optimal choice for a wide assortment of applications in environments where moisture, humidity, or extreme temperatures are present. This versatile alloy can easily be hard or soft-soldered, making it one of the most sought-after materials by electrical engineers and electronics manufacturers. UNS C10200 is often considered a go-to material when designing and constructing products such as telecommunications equipment, home appliances, motor components, power distribution systems, and even in the aerospace industry.

Copper C102 is a copper alloy containing 99.95% copper and .05% oxygen. This alloy is known for its excellent electrical conductivity and solderability. It also has good strength and ductility properties, making it ideal for various applications.

(Weight %)

| Cu* | Pb | Zn | Fe | P | Ag | As | O2 | Sb | Te | |

|---|---|---|---|---|---|---|---|---|---|---|

| Min | 99.95 | |||||||||

| Max | 0.0010 |

Copper C10200 has a high ductility and strength-to-weight ratio, making it suitable for various applications. Its tensile strength is greater than 20 ksi, while its yield strength ranges from 10-15 ksi. It also has an elongation rate greater than 40%. The hardness rating for this alloy is 55-65 Rockwell B (RB).

| Tensile | Yield | Elongation | |||

|---|---|---|---|---|---|

| O61 | Soft | 25-35 KSI | 15-25 KSI | 35% min | |

| H00 | 1/8 HD | 30-40 KSI | 18-25 KSI | 20% min | |

| H01 | 1/4 HD | 35-45 KSI | N/A | 15% min | |

| H02 | 1/2 HD | 40-50 KSI | N/A | 10% min | |

| H03 | 3/4 HD | 45-55 KSI | N/A | 5% min | |

| H04 | Full HD | 50-60 KSI | N/A | 1.5% min | |

| H08 | Spring | 60-70 KSI | N/A | 1.5% min |

The density of copper Alloy C102 is 8.9 g/cm3, with a melting point between 1083°C – 1150°C (1981°F – 2102°F). This alloy has excellent thermal and electrical conductivity due to its high copper content. It also has good corrosion resistance properties, making it ideal for various applications.

| English Units | C.G.S. Units | |

|---|---|---|

| Melting Point (Liquidus) | 1981°F | 1083°C |

| Density | .323 lb./cu. in. @ 68°F | 8.94 gm/cu. in. @ 20°C |

| Specific Gravity | 8.94 | 8.94 |

| Coefficient of Thermal Expansion | .0000094 per °F from 68°F to 212°F | .0000170 per °C from 20°C to 100°C |

| Coefficient of Thermal Expansion | .0000096 per °F from 68°F to 392°F | .0000173 per °C from 20°C to 200°C |

| Coefficient of Thermal Expansion | .0000098 per °F from 68°F to 572°F | .0000177 per °C from 20°C to 300°C |

| Thermal Conductivity | 226 Btu./sq. ft./ft./hr./°F @ 68°F | .934 cal./sq. cm./sec./°C @ 20°C |

| Electrical Resistivity (Annealed) | 10.3 Ohms (circ. mil./ft.) @ 68°F | 1.71 Microhm-cm @ 20°C |

| Electrical Conductivity* (Annealed) | 101% IACS @68°F | .586 Megohm-cm @ 20°C |

| Thermal Capacity (Specific Heat) | .092 Btu./lb./°F @ 68°F | .092 cal./gm./°C @ 20°C |

| Modulus of Elasticity (Tension) | 17,000,000 psi | 12,000 Kg./sq. mm |

| Modulus of Rigidity | 6,400,000 psi | 4,500 Kg./sq. mm |

Due to its excellent electrical and thermal conductivity, this alloy is often used in electrical components such as circuit boards, connectors, and switches. Due to its corrosion resistance properties, it can also be used in plumbing fixtures and electronic devices such as TVs and computers. Additionally, the C10200 Alloy can be used in automotive parts such as brake systems because of its strength and durability at higher temperatures.

|