| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Stud And Track Roll Forming Machine |

|---|---|

| Brand Name: | Sussman |

| Model Number: | RF-ST |

| Certification: | CE, SGS, ISO |

| Place of Origin: | Wuxi, China |

| MOQ: | 1 set |

| Price: | negotiable |

| Supply Ability: | 5 sets/month |

| Delivery Time: | 60 days after deposit |

| Packaging Details: | Film and steel |

| Main Motor Power: | 7.5KW |

| Hydraulic Station Power: | 5.5KW |

| Material thickness: | 0.6-1.2mm G350-G550 steel |

| Feeding width: | 182mm |

| Roller material:: | Skd-11 |

| Decoiler: | 3 Tons |

| Weight: | 3 tons |

| Warranty: | 1 year |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

1.2mm G550 Galvanized Steel C89 Model Light Gauge Steel Framing Machine For Prefabricated House Building

Main Specifications

| No. | Item | Specification | |||

| 1 | Powered Decoiler | ||||

| Loading weight | 3 tons | ||||

| Coil Inner Diameter | 460-520mm | ||||

| Power | 2.2kw | ||||

| 2 | Roll Forming Machine | ||||

| Dimension | 5Mx1Mx1.8M | ||||

| Weight | 3500KGS | ||||

| Material of Rollers | Material: GCr15 | ||||

| Processing Technic for Rollers | CNC machining, heat treatment HRC58-60,then processed by CNC lathe, plating finally | ||||

| Material of Shafts | 40Cr | ||||

| Processing Technic for Shafts | CNC machining, quenching and tempering HRC28-32,then processed by CNC lathe, plating and polishing finally | ||||

| Sheet Guiding Device | |||||

Holes Punching Device | (dimpling with screw holes,service hole,web notch,lip notch, truss end chamfer, swage, crimp) | ||||

| 3 | Control System | ||||

| Main control system | One Lenovo laptop and a control box inside of based frames of the machine | ||||

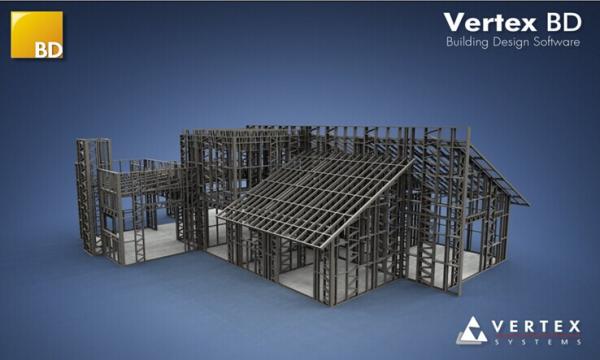

| Producing software | Special designed to match with the designing software Vertex | ||||

| Leaser Printing Device | USA Matthews Leaser Printing Device for painting spray logo and installation indicating number | ||||

| Remote-control device | Wireless remote-controller controls machine to go forward or backward or stop | ||||

| Brands of main components | PLC(self-developed),Relay (Schneider), proximity switch(Schneider), Encoder(Omron), Servo Motor(Xinjie) | ||||

| 4 | Servo System and Hydraulic System | ||||

| Servo motor | 5.5kw, taking with precision planetary gear reducer | ||||

| Hydraulic Station | 7.5KW;Hydraulic oil injection 200 litre | ||||

| 5 | Run-out Table | ||||

| Length | 3M | ||||

Profile photo

steel frames and trusses , high speed production , with Detailing

Software included

Steel thickness from 0.6 to 1.2mm G550 and G350

machine has ability to read CSV files via USB input heave roller

system .

Equipment description

1: Configuration of the machine

Uncoiler 1 set

Roll forming roller: 12 groups

PLC control system 1 set

Hydraulic cutting system: 1 set

Collection table

2: Working Process Flow of the omega profile forming machine

Uncoiling-Coil feeding-Guiding-Roll Forming-Punching (if needed) - Cutting-Collection table

3: Technical Parameters:

A: Power supply:

380V, 3 phases, 50 Hz (can be adjusted according to actual power supply conditions in different countries)

Main motor power: 7.5KW

Pump power: 5.5kw

B:Uncoiler:

Inner diameter: 460-520mm

Outer diameter: 1300mm

loading weight: 2T

C:Forming part:

Feeding thickness: 0.6-1.2mm

Feeding width: 50-500mm

Forming speed: 8-12m/min

Cutting Deviation: 10m±2mm

No. of Roller station: 12 groups

Roller material: GCr15

Material of shaft: Cr40

Diameter of shaft: 42mm

D:Hydraulic System:

Hydraulic pressure: 10-12 Mpa

Cutter material: SKD11

E:Control system:

Full-automatic NC-PLC control system

Control channel: Colored touch screen

|