| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Molybdenum Products |

|---|---|

| Brand Name: | JX |

| Model Number: | Mo75Cu35 |

| Certification: | ISO9001 |

| Place of Origin: | CHINA |

| Payment Terms: | L/C, T/T, D/P |

| Delivery Time: | 25 days |

| Company Info. |

| JINXING MATECH CO LTD |

| View Contact Details |

| Product List |

75/25 Polished Molybdenum Copper Alloy Bars Description

Molybdenum and tungsten have similar physical and chemical properties, and are often combined with copper to form copper-molybdenum and tungsten-copper alloys for use in harsher processing environments. 75/25 Polished Molybdenum Copper Alloy Bars are often made of pure molybdenum and oxygen-free copper through powder metallurgy technology. They have a series of excellent properties of molybdenum and copper. The most typical ratios of molybdenum and copper are 75/25 and 80/20. 75/25 Polished Molybdenum Copper Alloy Bars are mainly used in the production of vacuum and high temperature components, thermoelectric cooling components, and electronic packaging and heat dissipation materials for high power and frequency electronic devices.

Characteristic of 75/25 Polished Molybdenum Copper Alloy Bars:

1. High melting point, high density, thermal expansion coefficient

compatible with the thermal expansion coefficient of electronic

components

2. It has good strength and certain plasticity at room and medium

temperatures.

3. Special high temperature resistance: When the temperature

exceeds the melting point of copper, the copper will liquefy and

evaporate, absorbing heat and playing a cooling role.

4. After adding copper to the alloy, the hardness of the material

is reduced and the plasticity is improved. It can be processed into

parts with complex shapes, so it has the advantage of processing.

5. Good electrical conductivity, corrosion resistance, oxidation

resistance, long service life

75/25 Polished Molybdenum Copper Alloy Bars Specifications:

| Grade | Mo75Cu25/Mo80Cu20 |

| Technique | Hot Rolling,Cold Rolling,Sintering,Annealing,Drawing |

| Purity | Moly Content :50%-85% |

| Diameter | 10mm-300mm |

| Length | 5-1000mm |

| Density | 9.5g/cm3-10g/cm3 |

| Thermal Conductivity | 160W/(m·K) |

| Shape | Round |

| Surface | Polishing,Alkali Cleaning,Machining,Grinding,Ground,Black Oxide, etc. |

| Standard | GB,JIS,ASTM,DIN,EN,ISO |

| Certification | ISO9001:2008 |

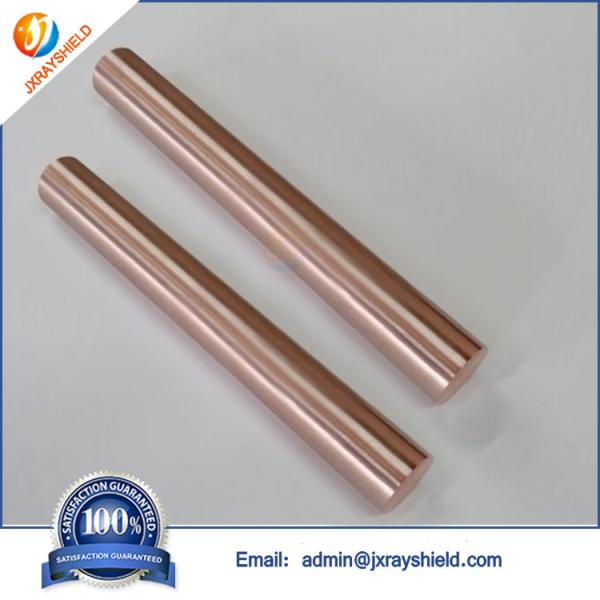

75/25 Polished Molybdenum Copper Alloy Bars Pictures:

|