| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Molybdenum Products |

|---|---|

| Model Number: | Molybdenum Rod Electrodes |

| MOQ: | Negotiate |

| Price: | Negitionable |

| Payment Terms: | L/C, D/A, D/P, T/T |

| Supply Ability: | 10000sets/month |

| Delivery Time: | 30 days after receiving down payment |

| Packaging Details: | Standard export cartons |

| Name: | Molybdenum Rod Electrodes |

| Application: | automotive, aerospace, and electronic appliance |

| Feature: | High-temperature strength |

| Surface: | Chemical Cleaned |

| Specifications: | according to customer requirements |

| Material: | Mo1, Mo-La, TZM |

| Company Info. |

| Luoyang Hypersolid Metal Tech Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

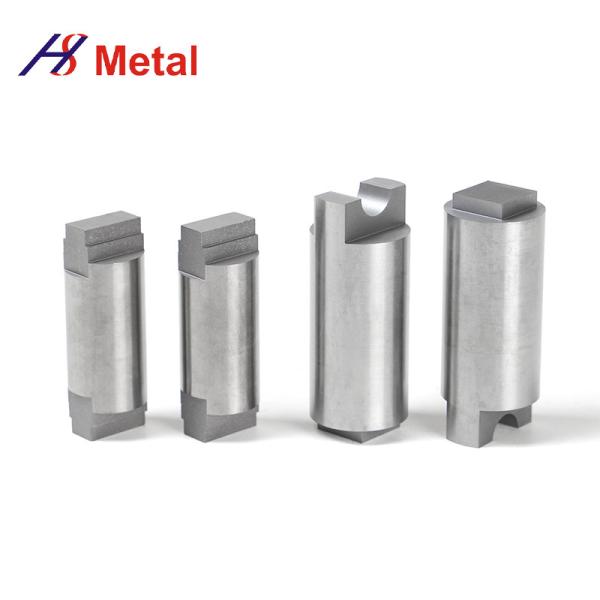

Mo1, Mo-La, TZM Molybdenum Rod Electrodes Chemical Cleaned

Molybdenum Rod Electrodes Application

1) Used for glass industry, the fields of rare earth industry, refractory fiber industry and so on.

2) Used as vacuum material, cathode for emitting tube, and high temperature electrodes etc.

Product parameters:

Molybdenum electrodes are used for welding processes, e.g. in resistance welding. TZM (titanium-zirconium-molybdenum) is made from molybdenum by adding small amounts of small carbides.

Appearance: silver gray metallic luster

Density:>10.2g/cm

Purity: Mo>99.95%

Specifications:according to customer requirements or drawings, accept customized products.

Molybdenum electrode without defects (missing surface, missing angle, diaphragm layer, cracks)

Molybdenum electrode folding or adjustment according to user’s needs.

Atomic number | 42 |

CAS number | 7439-98-7 |

Atomic mass | 95.94 [g/mol] |

Melting point | 2620 °C |

Boiling point | 4639 °C |

Density at 20 °C | 10.22 [g/cm] |

Crystal structure | Body-centered cubic |

Coefficient of linear thermal expansion at 20 °C | 5.210-6[m/(mK)] |

Thermal conductivity at 20 °C | 142 [W/(mK)] |

Specific heat at 20 °C | 0.25 [J/(gK)] |

Electrical conductivity at 20 °C | 17.9106[S/m] |

Specific electrical resistance at 20 °C | 0.056 [(mm2)/m] |

|