| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Door Frame Roll Forming Machine |

|---|---|

| Brand Name: | CHBEST |

| Model Number: | XY 100 |

| Certification: | CE/BV/SGS |

| Place of Origin: | China Hebei |

| MOQ: | 1 set |

| Supply Ability: | 20 sets/month |

| Delivery Time: | 30-40 days |

| Packaging Details: | plastic film for naked machine |

| Product name: | Full Auto Steel Profile Door Frame Roll Forming Machine Hydraulic Punching |

| Color: | Blue or according to your request |

| Warranty: | 2years |

| Driven system: | Chain or gear box |

| Control system: | PLC |

| Cutting type: | Hydraulic |

| Company Info. |

| Cangzhou Best Machinery Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

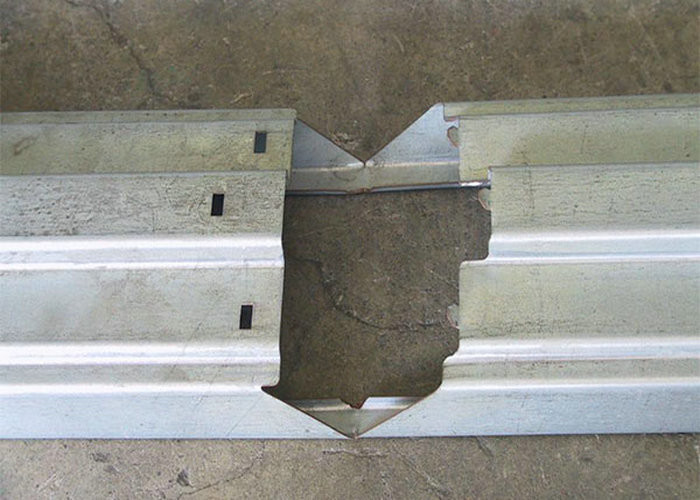

Full Auto Steel Profile Frame Roll Forming Machine Hydraulic Punching

Working flow

Decoiler---------leveling--------punching---------roll

forming--------cut to length----------output table

Machine components:

| No. | Name | Qty. |

| 1 | Decoiler | 1set |

| 2 | Feeding and guiding device | 1set |

| 3 | Roll forming machine | 1set |

| 4 | Punching machine with servo feeding | 1set |

| 5 | Hydraulic cutting device | 1set |

| 6 | PLC control box | 1set |

| 7 | output table | 1set |

Techincal description:

A Manual decoiler

(1) Inner Diameter: Φ450 – Φ550 mm

(2) Out Diameter: 1500 mm

(3) Max. Loading Capacity: 3000 kg

B. Main roll forming

1) Material of frame : (high grade) 360mm H shape steel welding

2) Thickness of middle plate : 20mm

3) Step of forming roller : 18steps

4) Diameter of shaft (solid shaft): 80mm

5) Material of shaft (solid shaft): (high grade) 45# Steel

6) Drive type of roll forming machine : drive by chain

7) Chain : 38.1 mm (high grade)

8) Bearing : 6312 (high grade)

9) Reducer : 8# cycloid reducer (high grade)

10) Power of main motor : 11KW

11) Voltage : 380V/50Hz/3phase

12) Feeding width : 245mm-385mm

13) Suitable coil thickness : accepted thickness for steel coil is

1.6mm-2.0mm.

C Cutting device

1) Cutting: Hydraulic cutting

2) Auto cutting when reach the set length.

3) Hydraulic power: 7.5KW

4) Blade material: Cr12,quenched 55°-60°

5) Working pressure:16mpa

6) Cutting tolerance: +/- 1.5mm

D Punching

1) Hydraulic punching AFTER roll forming

2) Power:7.5kw

E Control system

| PLC | PLC Frequency Control System with touch screen |

| PLC Brand | Delta |

| Encoder Brand | Omron |

| Length error | ±2mm |

| Transducer | Panasonic |

RFQ

Q: Can you make the machine according to my design or proto type?

A: Yes. We have an experienced team for working out the most

suitable design and production plan for the machine that you are

going to book with us

Q: Are you a factory or trading company ?

A: We are a factory?

Q: Where is your factory located?

A: Our factory is located in Botou City,Hebei Province, China. All our clients, from home or abroad, are warmly welcome to visit us !

Q: How do you guarantee the quality of the products?

A: Strict product quality, unqualified resolute don't factory.This is the tenet of our factory

Every one of our products have strict testing procedures, must be 100% quality assurance.

Q: How can we be assured that you will deliver us quality machine with spare parts?

A: 1. Customers to send the technical people to our factory for

checking the quality.

2. We can send the technicians to the buyer`s factory for the installation of the machine.

3. Good aftersales-service, its free of charge during the warranty period.

|