| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Aluminum Conductor Steel Reinforced |

|---|---|

| Brand Name: | Zhenglan Cable |

| Model Number: | ACSR CONDUCTOR |

| Certification: | 3C; ISO 9001:2015, ISO 14001:2005, OHSAS 18001:2007 |

| Place of Origin: | Henan, China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C, Western Union |

| Delivery Time: | 10days |

| Packaging Details: | Wooden drum, wood and steel drum,as customer's request |

| Material: | Aluminum Conductor Steel Reinforced |

| Out Sheath: | None |

| Core: | AL/Steel |

| Cable Drum Length: | Customized |

| characted: | Bare Conductor |

| Total Area: | 18.7~1211 |

| Sample: | Free |

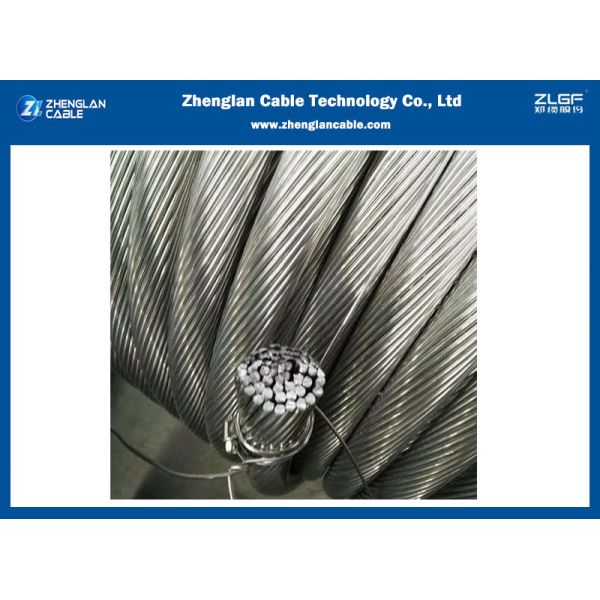

| Conductor Type: | Stranded Conductor |

| Company Info. |

| Zhenglan Cable Technology Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Free Samples Coyote ACSR 26/2.54 + 7/1.90mm Aluminum Conductor Steel Reinforced Bare Overhead Power Transmission Line

APPLICATION

ACSR conductors are widely used for electrical power transmission over long distances, which occupies an important position in the power and transmission line industry. Steel core aluminum stranded wire is formed by twisting aluminum wire and steel wire, which is suitable for overhead transmission lines.

STANDARD

Basic design to BS 215-2 / BS EN 50182 / IEC 61089 / ASTM B 232/B 232M / DIN 48204 / JIS C 3110 standards.

CONSTRUCTION

ACSR conductors are formed by several wires of aluminum and steel can be varied to obtain the relation between current-carrying capacity and mechanical strength best suited to each application.

By varying the relative proportions of aluminium and steel, the required characteristics for any particular application can be reached. A higher U. T. S. Can be obtained, by increasing steel content, and a higher current carrying capacity by increasing aluminium content.

TECHNICAL DATA

| Numbers of Wires | Modules of Elasticity | Coeficient of linear Expansion | |||

| AL | STEEL | Kg/mm2 | Lb/in2 | 1/Cº | 1/Fº |

| 6 | 1 | 81 | 11.5 x106 | 19.1 x10-6 | 10.6 x10-6 |

| 6 | 7 | 77 | 11.0 x106 | 19.8 x10-6 | 11.0 x10-6 |

| 12 | 7 | 107 | 15.2 x106 | 15.3 x10-6 | 8.5 x10-6 |

| 18 | 1 | 67 | 9.5 x106 | 21.2 x10-6 | 11.8 x10-6 |

| 24 | 7 | 74 | 10.5 x106 | 19.6 x10-6 | 10.9 x10-6 |

| 26 | 7 | 77 | 10.9 x106 | 18.9 x10-6 | 10.5 x10-6 |

| 28 | 7 | 79 | 11.2 x106 | 18.4 x10-6 | 10.2 x10-6 |

| 30 | 7 | 82 | 11.6 x106 | 17.8 x10-6 | 9.9 x10-6 |

| 30 | 19 | 80 | 11.4 x106 | 18.0 x10-6 | 10.0 x10-6 |

| 32 | 19 | 82 | 11.7 x106 | 17.5 x10-6 | 9.7 x10-6 |

| 54 | 7 | 70 | 9.9 x106 | 19.3 x10-6 | 10.7 x10-6 |

| 54 | 19 | 68 | 9.7 x106 | 19.4 x10-6 | 10.8 x10-6 |

CONSTRUCTION PARAMETERS

• IEC 60189

| Code | Nominal Area | Stranding | Overall Diameter | Weight | Breaking Load | Electrical Resistance @20° | Current Rating* | |||

| AL | STEEL | TOTAL | AL | STEEL | ||||||

| mm2 | mm2 | mm2 | No.xmm | No.xmm | mm | Kg/Km | KN | Ω/Km | A | |

| 16 | 16 | 2.67 | 18.7 | 6/1.84 | 1/1.84 | 5.52 | 64.6 | 6.08 | 1.7934 | 85 |

| 25 | 25 | 4.17 | 29.2 | 6/2.30 | 1/2.30 | 6.9 | 100.9 | 9.13 | 1.1478 | 112 |

| 40 | 40 | 6.67 | 46.7 | 6/2.91 | 1/2.91 | 8.73 | 161.5 | 14.4 | 0.7174 | 150 |

| 63 | 63 | 10.5 | 73.5 | 6/3.66 | 1/3.66 | 10.98 | 254.4 | 21.63 | 0.4555 | 198 |

| 100 | 100 | 16.7 | 117 | 6/4.61 | 1/4.61 | 13.83 | 403.8 | 34.33 | 0.2869 | 263 |

| 125 | 125 | 6.94 | 132 | 18/2.97 | 1/2.97 | 14.85 | 397.9 | 29.17 | 0.2304 | 299 |

| 125 | 125 | 20.4 | 145 | 26/2.47 | 7/1.92 | 15.64 | 503.9 | 45.69 | 0.231 | 302 |

| 160 | 160 | 8.89 | 169 | 18/3.36 | 1/3.36 | 16.8 | 509.3 | 36.18 | 0.18 | 347 |

| 160 | 160 | 26.1 | 186 | 26/2.80 | 7/2.18 | 17.74 | 644.9 | 57.69 | 0.1805 | 351 |

| 200 | 200 | 11.1 | 211 | 18/3.76 | 1/3.76 | 18.8 | 636.7 | 44.22 | 0.144 | 398 |

| 200 | 200 | 32.6 | 233 | 26/3.13 | 7/2.43 | 19.81 | 806.2 | 70.13 | 0.1444 | 402 |

| 250 | 250 | 24.6 | 275 | 22/3.80 | 7/2.11 | 21.53 | 880.6 | 68.72 | 0.1154 | 458 |

| 250 | 250 | 40.7 | 291 | 26/3.50 | 7/2.72 | 22.16 | 1007.7 | 87.67 | 0.1155 | 461 |

| 315 | 315 | 21.8 | 337 | 45/2.99 | 7/1.99 | 23.91 | 1039.6 | 79.03 | 0.0917 | 526 |

| 315 | 315 | 51.3 | 366 | 26/3.93 | 7/3.05 | 24.87 | 1269.7 | 106.83 | 0.0917 | 530 |

| 400 | 400 | 27.7 | 428 | 45/3.36 | 7/2.24 | 26.88 | 1320.1 | 98.36 | 0.0722 | 607 |

| 400 | 400 | 51.9 | 452 | 54/3.07 | 7/3.07 | 27.63 | 1510.3 | 123.04 | 0.0723 | 610 |

| 450 | 450 | 31.1 | 481 | 45/3.57 | 7/2.38 | 28.56 | 1485.2 | 107.47 | 0.0642 | 651 |

| 450 | 450 | 58.3 | 508 | 54/3.26 | 7/3.26 | 29.34 | 1699.1 | 138.42 | 0.0643 | 655 |

| 500 | 500 | 34.6 | 535 | 45/3.76 | 7/2.51 | 30.09 | 1650.2 | 119.41 | 0.0578 | 693 |

| 500 | 500 | 64.8 | 565 | 54/3.43 | 7/3.43 | 30.87 | 1887.9 | 153.8 | 0.0578 | 697 |

| 560 | 560 | 38.7 | 599 | 45/3.98 | 7/2.65 | 31.83 | 1848.2 | 133.74 | 0.0516 | 741 |

| 560* | 560 | 70.9 | 631 | 54/3.63 | 19/2.18 | 32.68 | 2103.4 | 172.59 | 0.0516 | 745 |

| 630 | 630 | 43.6 | 674 | 45/4.22 | 7/2.81 | 33.75 | 2079.2 | 150.45 | 0.0459 | 794 |

| 630* | 630 | 79.8 | 710 | 54/3.85 | 19/2.31 | 34.65 | 2366.3 | 191.77 | 0.0459 | 798 |

| 710 | 710 | 49.1 | 759 | 45/4.48 | 7/2.99 | 35.85 | 2343.2 | 169.56 | 0.0407 | 851 |

| 710* | 710 | 89.9 | 800 | 54/4.09 | 19/2.45 | 36.79 | 2666.8 | 216.12 | 0.0407 | 856 |

| 800* | 800 | 34.6 | 835 | 72/3.76 | 7/2.51 | 37.61 | 2480.2 | 167.41 | 0.0361 | 910 |

| 800* | 800 | 66.7 | 867 | 84/3.48 | 7/3.48 | 38.28 | 2732.7 | 205.33 | 0.0362 | 912 |

| 800* | 800 | 101 | 901 | 54/4.34 | 19/2.61 | 39.09 | 3004.9 | 243.52 | 0.0362 | 916 |

| 900* | 900 | 38.9 | 939 | 72/3.99 | 7/2.66 | 39.9 | 2790.2 | 188.33 | 0.0321 | 972 |

| 900* | 900 | 75 | 975 | 84/3.69 | 7/3.69 | 40.59 | 3074.2 | 226.5 | 0.0322 | 974 |

| 1000* | 1000 | 43.2 | 1043 | 72/4.21 | 7/2.80 | 42.08 | 3100.3 | 209.26 | 0.0289 | 1031 |

| 1120* | 1120 | 47.3 | 1167 | 72/4.45 | 19/1.78 | 44.5 | 3464.9 | 234.53 | 0.0258 | 1096 |

| 1120* | 1120 | 91.2 | 1211 | 84/4.12 | 19/2.47 | 45.31 | 3811.5 | 283.17 | 0.0258 | 1100 |

| 1250* | 1250 | 102 | 1352 | 84/4.35 | 19/2.61 | 47.85 | 4253.9 | 316.04 | 0.0232 | 1165 |

| 1250* | 1250 | 52.8 | 1303 | 72/4.70 | 19/1.88 | 47 | 3867.1 | 261.75 | 0.0231 | 1163 |

| 1120* | 1120 | 91.2 | 1211 | 84/4.12 | 19/2.47 | 45.31 | 3811.5 | 283.17 | 0.0258 | 1100 |

Why you choose us?

|