| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Wood Pellet Production Line |

|---|---|

| Brand Name: | Zhongdebao |

| Model Number: | PL-1-10TPH |

| Certification: | CE BV |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | price negotiable |

| Payment Terms: | L/C,T/T,Western Union |

| Supply Ability: | 100sets per month |

| Delivery Time: | 5-8 working days |

| Packaging Details: | wooden case package and directly loaded in the container |

| Application: | Chips, Biscuit, Snack, Puff Snack/Corn Snack/Extrusion Snack Process Line, Frying Snacks pellet making Extruder machine / production line |

| After-sales service provided: | Engineers available to service machinery overseas, Field installation, commissioning and training, Overseas service center available, Video technical support |

| Voltage: | 380V/50HZ, 380v, 50hz, 380V/50HZ/Three Phase, 220V/50HZ/Single Phase or Change As Rquired |

| Power(w): | 45KW, 256kw, 195kw, 80KW, 22/30/55/75/90kw |

| Warranty: | 1 Year, one year, 12 MONTHS |

| Weight: | 500kg, 6000kg, 1200kg, 2-10TON, 2000 |

| Dimension(l*w*h): | 30000*5000*3500mm, 3.2*1.1*2m, 21*2*3m, 3.5x1.05x1.96m, As per capacity |

| Condition: | New |

| Capacity: | 1000kg/h to 10tons /h |

| Material: | Carbon steel Alloy steel |

| Motor: | Simens, Chinese motor or Simense |

| Product name: | biomass wood pellet production line |

| Color: | blue white green any color can be customized |

| Type: | biomass wood pellet producing line |

| Raw material: | wood chips Eucalyptus pine birch poplar Rice husks, peanut husks, melon seed husks, bamboo shavings, bagasse, palm husks, twigs, branches, bark, leaves, wood scraps; Large furniture factory, wood factory, wood chips produced by various kinds of wood in the |

| Main motor: | 22kw 30kw 37kw 55kw |

| Output: | 300kg/h 500kg/h 800kg/h 1000kg/h 1.5ton/h 1.8-2tons/h 2.5-3tons/h |

| Year: | 2023 |

| Company Info. |

| ZhengZhou ZhongDeBao Industrial Co., LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

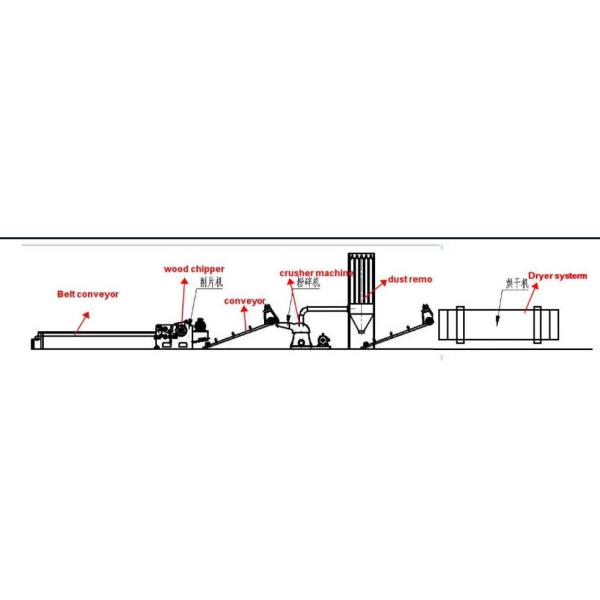

1TPH-10TPH Biomass Wood Chips Eucalyptus Pine Birch Poplar Pellet Production Line

To make the wood into chips with less than 5cm . Drum type wood chipper is an ideal equipment to produce large capacity wood chips . The uniquely designed presure reducing device ensures the long-term stable operation of the equipment .

2. Crushing section :

The wood crushing system can make wood chips into wood sawdust. The hammer mill is applied mainly to grind the raw materials to make it suitable to make pellets . The impeller variable frequency feeder is used to ensure work efficiency .

3. Drying section :

The rotatry drum dryer is designed to reduce the moisture of the unqualitified raw material , for which the mositure is too high . the moisture will be from 50% reduce to 15-18% . Burning stove to supply hot air to drum dryer .

4. Pelleting section :

This is the core equipment of the production line . Used to make wood sawdust into pellets . The more wear-resistant 42CrMo ring die is used to produce wood pellets with a high compression ratio .

5. Cooling section :

To cool the pellets to room temperature and remove the moisture in the pellets , The hardness of the pellets will become stronger . So as to obtain better hardness and strength . It can also improve transportaion capacity and storage capacity .

6. Packing section :

The pellets are packed into plastic bag from 10kg-100kg . then use the thermoplastic sealing machine to sew . these can make the pellets dry and water-proof . To extend the wood pellets storage time .

For the pellet mold/die the diameter generally will be 6mm or 8mm .

The finished sample pellet for your reference :

|