| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Boiler Tube |

|---|---|

| Brand Name: | YUHONG |

| Model Number: | ASME SA179/ASTM A179 |

| Certification: | ISO9001-2008 |

| Place of Origin: | China |

| MOQ: | 100 kgs |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 100 tons per month |

| Delivery Time: | Depends on quantity |

| Packaging Details: | PLYWOOD CASE,BUNDLE,WOVEN BAG |

| Standard: | ASME SA179/ASTM A179 |

| Grade: | A179 |

| O.D: | 1/8"- 3" (3.2mm-76.2mm) |

| Type: | Seamless, Cold drawn |

| Wall thinkness: | MW. |

| Test: | ET, UT, HT, PT |

| Company Info. |

| Yuhong Group Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

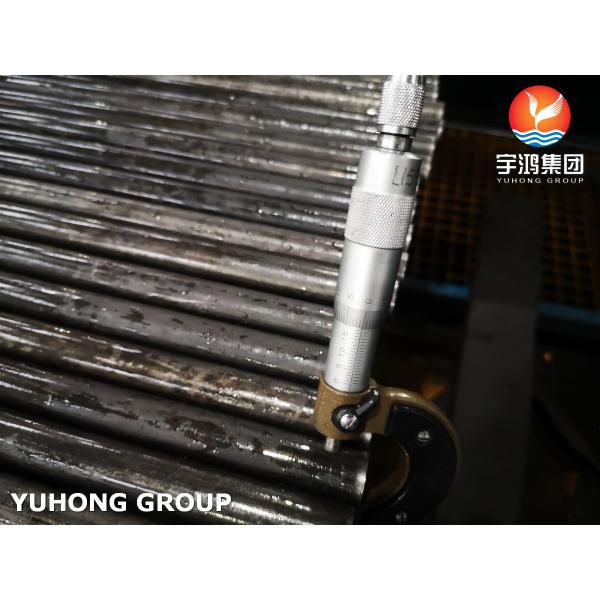

ASTM A179 / SAME SA179 Carbon Steel Seamless Tube Heat Exchange Tube

Description

ASTM A179 (SA 179) standard specification covers seamless cold drawn low-carbon steel pipe, for tubular heat exchanger, condensers, and other similar heat transfer equipment.

A179 tubes are used widely due to its excellent tensile strength and yield strength. The properties of the SA179 grade is highly unmatched, some of them are good corrosion resistance, oxidation resistance, pitting resistance, resistance to acid, crevice corrosion resistance and excellent strength.

ASTM A179 Seamless Tube Chemical Composition

Chemical Composition | C | Mn | P≤ | S≤ | Si≤ |

|---|---|---|---|---|---|

0.06-0.18 | 0.27-0.63 | 0.035 | 0.035 | 0.35 |

ASTM A179 Seamless Tube Mechanical Property

Steel Grade | Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation (%) |

|---|---|---|---|

ASTM A179 | ≥180 | ≥325 | ≥35 |

Wall Thickness Tolerance of test requirements

Seamless, Cold-Finished Tubes | ||

Outside Diameter | Wall thickness Tolerance % | |

Over (+) | Under (-) | |

1 ½ (38.1) | 20 | 0 |

Over 1½ (38.1) | 22 | 0 |

Test stardstand.

Hardness requirements

The hardness coefficient of the steel pipe shall not exceed 72 HRB

Mechanical properties test requirements 1 Flattening test Take 2

steel pipes from each batch (Note 2) or use a fragment for testing.

Expansion test

Take 1 specimen from each of 2 steel pipes from each batch or use a

fragment for testing.

If the bending test is used instead of the expansion test, when the

wall thickness of the steel pipe is less than 10% of the outer

diameter, take 1 specimen from each batch of steel pipes or use a

fragment for bending test. Steel pipes that are not within the

above specification range do not need to be bent.

Hardness test

Take 2 steel pipes from each batch for Rockwell hardness test. "One

batch" should include all steel pipes with the same nominal

diameter and wall thickness produced by the same heat treatment and

the same batch of steel before cutting. When the final heat

treatment is carried out in the same heat treatment furnace of the

same model, "a batch" shall refer to all steel pipes of the same

size heat treated in the same furnace. When the final heat

treatment is carried out in a continuous heat treatment furnace, "a

batch" shall include all steel pipes of the same size, heat, heat

treatment at the same temperature, time and speed in the same

furnace.

Hydrostatic test

All tube shall be subjected to hydrostatic test, or non-destructive

electrical test pipes shall be used when the purchaser requires

otherwise.

Application

Cold drawn tube

Condenser tubes

Heat exchanger tubes

Low carbon steel

Seamless tube

|