| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Dry Mortar Plant |

|---|---|

| Brand Name: | MG |

| Model Number: | MGDM3.7 |

| Certification: | CE BV ISO 9001:2008 |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 10 sets per month |

| Delivery Time: | 20 working days |

| Packaging Details: | Stand seaworthy packaging |

| Raw Material: | Sand,Cement,Gypsum,etc |

| Application: | Dry Powder Mixing |

| Capacity: | 10-30 T/H |

| Color: | Grey/White/Blue Or Customized |

| Power: | 83kw |

| Size: | 8000*8000*8000mm |

| Workers: | 3-4 Persons |

| Formula: | Provided |

| Mixing Time: | 3-5 Minutes/Batch |

| Packing Machine: | Valve Port Packing Machine |

| Company Info. |

| Zhengzhou MG Industrial Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

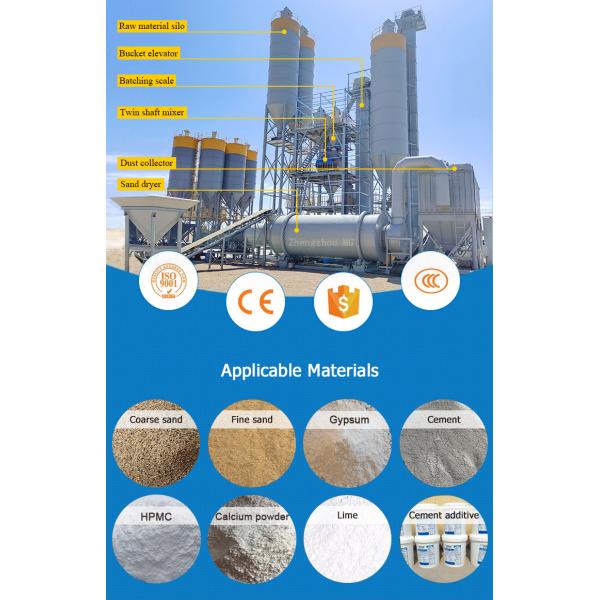

Fully Automatic Dry Powder Mortar Mixing Machine Wall Putty Sand Cement Mixer Ceramic Tile Adhesive Manufacturing Plant For Sale

1,Description of Ceramic Tile Adhesive Manufacturing Plant.

This production line adopted latest Germany Technology, the silo is in tower type,and latest management system is applied in automatic control,improved the man-friendly operation in large extent.The capacity of this automatic dry mortar production line can reach 10-80 T/H.

2.Advantages of Ceramic Tile Adhesive Manufacturing Plant.

1, A high degree of intelligence. It is controlled by the control

system with program and realizes total automation of automatic

batching,automatic weighing, automatic feeding, automatic mixing

and automatic packing.

2, The design of tower layout structure, shorten the transportation

distance and increases the production capacity.

3. The use of agravic biaxial mixer has high mixing uniformity, and

materials with large differences in physical properties particle

size and shape do not easily segregate when mixed.

| Model | Capacity | Equipment height | Total power | Worker required | Workshop required |

| 2000L Mixer | 10-12T/H | 8-10m | 80-90KW | 2-3 Person | 500-600m2 |

| 3000L Mixer | 15-20T/H | 10-14m | 90-100KW | 3-4 Person | 600-800m2 |

| 4000L Mixer | 20-30T/H | 10-14m | 100-120KW | 3-4 Person | 600-800m2 |

| 6000L Mixer | 30-50T/H | 15-20m | 100-120KW | 3-4 Person | 800-1000m2 |

| 10000L Mixer | 50-80T/H | 20-25m | 120-150KW | 3-4 Person | 1000-1200m2 |

3. Raw Materials of Ceramic Tile Adhesive Manufacturing Plant.

I Cementing materials: cement, lime, gypsum.

II Aggregate: yellow sand, quartz sand, limestone, dolomite,

expanded perlite, etc.

III Mineral admixture: industrial byproduct, industrial slag, fly

ash, pozzolana, fine silica powder, etc.

IV Water-retention and thickening material.

V Chemical additives.

4. Application of Ceramic Tile Adhesive Manufacturing Plant.

Bonding mortar: Masonry mortar, wall and floor tile glue mortar,

ceramic tile adhesive mortar,anchorage mortar etc.

Decoration mortar: Decorative plaster mortar, inner and outer wall

putty mortar, colorful decoration mortar etc.

Protection mortar: Water-proof mortar, anti-corrosion mortar, self

level mortar, wear resistance mortar, thermal insulation mortar,

sound insulation mortar, repair mortar, anti-crack mortar,

mildew-proof mortar, shielding mortar etc.

5.Our company.

Zhengzhou MG Industrial Co,.Ltd,one of the leading manufacturers of building material equipment in China,always provides the customers from all over the world with professional efficient solutions to high quality machine,formula technology and special additives for more than 20 years.

1. What is the capacity of your automatic dry mortar production

line?

A: We have dry mortar production line capacity ranges 3-50T/H as your

requirement, And also we can customize the production line for you.

A: We can provide you turnkey solution of dry mortar mixing equipment from working site planning to dry mortar machines, transportation, installation and training, formula of dry mortars, after-sales services, life time technical support etc.

|