| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Ceramic Ball Bearings |

|---|---|

| Brand Name: | CSQ |

| Model Number: | 695 Ce |

| Certification: | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001, IATF16949 |

| Place of Origin: | China |

| MOQ: | 100 pcs |

| Price: | Negotiable |

| Payment Terms: | T/T or Paypal |

| Supply Ability: | 50,000 pcs per month |

| Delivery Time: | 15-20 days |

| Packaging Details: | Customized packing of 100 pcs |

| Name: | 695 Ceramic Ball Bearings for Underwater Equipment |

| Category: | Miniature Ceramic Ball Bearings |

| Ring: | Zirconia |

| Ball: | Zirconia |

| Cage: | Nylon |

| Sealing: | Double Rubber Sealings |

| Precision: | P6/ P5 |

| Clearance: | C0 |

| Packing: | Customized of 100 pcs |

| Application: | Underwater Equipment |

| Features: | Easy Maintenance, Durability and Corrosion Resistance |

| Company Info. |

| Beijing Zhongxing Shiqiang CERAMIC BEARING Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

The 695 ceramic ball bearing is a specific type of bearing that

incorporates ceramic materials in its construction. The rings and

balls are made of zirconia material, the cage is nylon material and

with double rubber sealings:

1. Material Composition:

The ball bearing consists of ceramic components. Ceramic materials

offer several advantages over traditional metal bearings, including

excellent hardness, corrosion resistance, and low friction. These

properties contribute to the bearing's durability and performance.

2. Dimensions:

The outer diameter is 13mm, inner diameter is 5mm and the height is

4mm, which can be called miniature ceramic ball bearings.

3. Operating Characteristics:

Ceramic bearings are known for their high-speed capabilities, low

maintenance requirements, and long service life. The low friction

properties of ceramic materials reduce heat generation and energy

loss during operation, making them suitable for high-performance

applications. Additionally, the corrosion resistance of ceramic

bearings means they can operate in harsh environments without

significant degradation.

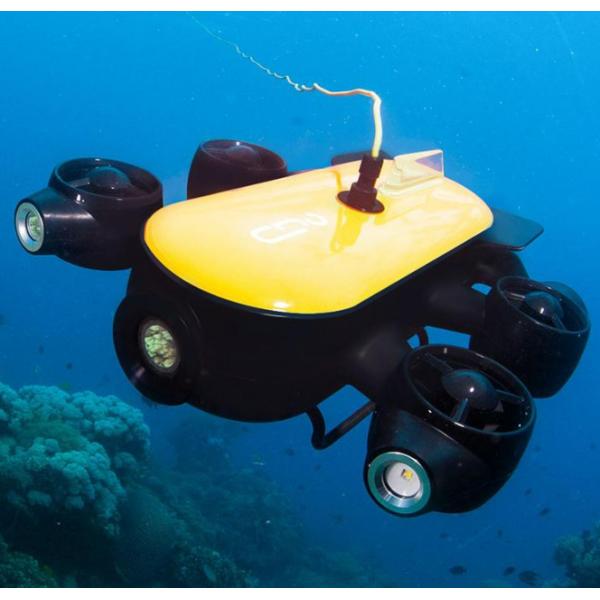

4. Applications:

With its excellent corrosion resistance, durability and easy

maintenance, the 695 ceramic ball bearing is suitable for

underwater equipment.

The selection of 695 ceramic ball bearings for underwater equipment

is based on several key factors that contribute to their

suitability for such applications. Here are some reasons why 695

ceramic ball bearings are often chosen for underwater equipment:

1. Corrosion Resistance: Ceramic materials, including the type used in 695 ball bearings,

exhibit excellent corrosion resistance. This is crucial in

underwater environments where equipment is constantly exposed to

saltwater and other corrosive elements. Ceramic bearings can

withstand these harsh conditions without succumbing to corrosion,

ensuring longer service life and reliability.

2. High Hardness and Durability: Ceramic materials are known for their exceptional hardness and

durability. This makes 695 ceramic ball bearings highly resistant

to wear and tear, even under high loads and speeds. This durability

is essential for underwater equipment that may be subject to

extreme operating conditions and requires bearings that can

withstand the demands of constant use.

3. Smooth Operation: Ceramic ball bearings offer a smooth and friction-free operation.

This is crucial for underwater equipment that requires precision

and smooth movement, such as pumps, motors, and other mechanical

components. The low friction characteristics of ceramic bearings

reduce energy loss and heat generation, improving overall

efficiency and performance.

4. Non-Magnetic and Non-conductive: Ceramic materials are non-magnetic and non-conductive, making 695

ceramic ball bearings suitable for use in underwater equipment that

requires electrical isolation or is sensitive to magnetic fields.

This property can be advantageous in various applications, such as

those involving sensors, electrical components, or magnetic

devices.

5. Environmentally Friendly: Ceramic bearings are generally considered environmentally friendly

compared to some traditional bearing materials. They do not contain

harmful metals or chemicals and can be recycled or disposed of

without causing significant environmental impact. This is an

important consideration for underwater equipment used in sensitive

ecosystems or areas with strict environmental regulations.

In summary, 695 ceramic ball bearings are chosen for underwater

equipment due to their corrosion resistance, high hardness and

durability, smooth operation, non-magnetic and non-conductive

properties, and environmental friendliness. These factors combined

make them an excellent choice for underwater applications that

require reliable and long-lasting bearing solutions.

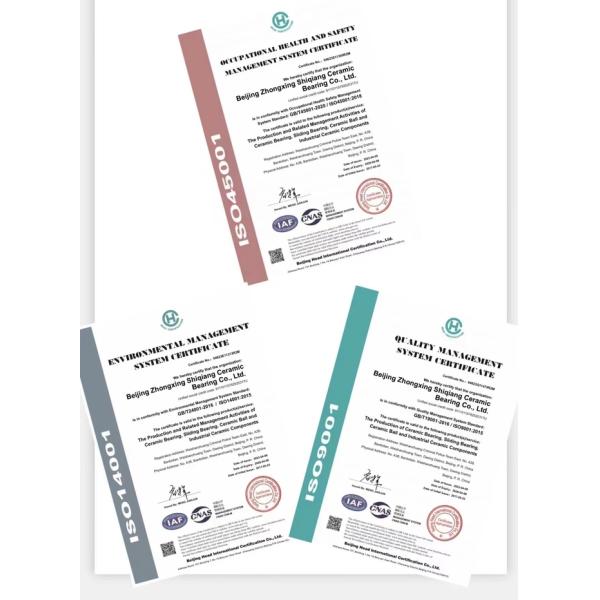

Our company is specialized in producing ceramic balls and ceramic

bearings, the technology is inherited from the parent company:

Beijing Zhongxing Shiqiang Ceramic Bearing Company, which already

has FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 certifications.

The factory covers an area of about 4000 square meters, equipped

with automatic production and assembly line, ball grinding machine

and other production equipment, as well as a variety of bearing

testing equipment. We have professional testing equipment and

technicians. All products are 100% strictly inspected before

exporting, including appearance defect inspection, roundness,

roughness and geometry size, and all products meet ISO

international standards.

At present, our company mainly produces ceramic ball bearings,

sliding bearings, ceramic balls and ceramic industrial parts. The

production materials are high performance ceramic materials, mainly

SSIC, Si3N4 and ZrO2 material. And we have a series of professional

production and inspection equipments, such as the HIP (High

temperature Insostatic Pressing) Equipment is from ABB Sweden, the

inspection equipments are mostly from Mitutoty. The products will

be strictly 100% inspected before export.

Our main customers are mainly located in Germany, United Kingdom

and other European countries and Japan, Korea and other Asian

countries.

We dedicate to provide high level products and technical services,

our experienced and professional team is committed to handling your

enquiry quickly and accurately.

1. Q:What the MQQ of your company?

A:MQQ is 100 pcs.

2. Q:Could you accept OEM and customize?

A:YES,we can customize according to your sample or drawing.

3. Q:Could you supply sample for free?

A:Yes,we can supply sample for free, but not charge the freight.

4. Q:Does your factory have any certificate?

A:yes.we have FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001, IATF16949.

5. Q:IS you company factory or Trade Company?

A:We are the supplier and we have our own factory.

6. Q:Could you tell me the material of our bearing?

A:We have ZrO2(Zirconia), Silicon Carbide(SSiC), Silicon

Nitride(Si3N4), Aluminia(Al2O3).

7. Q:Could you offer door to door service?

A:Yes,by express(DHL,FEDEX,TNT,UPS).

8. Q:Could you tell me the payment term of your company can accept?

A:T/T.

9. Q:Your factory how to control the quality?

A: All bearing parts before the production and the production

process, strict inspection by 100%, including crack detection,

roundness, hardness, roughness, and the geometry size, all bearing

meet ISO international standard.

|