| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | EPC Engineering |

|---|---|

| Brand Name: | Shaanxi Chengda |

| Model Number: | Ladle capacity100t |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1set |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Supply Ability: | Complete production supply chain, supply on time, and meet quality standards |

| Delivery Time: | 2 months |

| Price: | The price will be negotiated based on the technical requirements and supply scope of Party A |

| Packaging Details: | Discuss according to the specific requirements of Party A |

| Ladle capacity: | 10-160t |

| Transformer capacity: | 18000kva |

| Electrode diameter: | Ø700mm |

| Fuel: | Electric |

| Delivery time: | 30days |

| Warranty of core components: | 1 Year |

| Company Info. |

| Shaanxi CHENGDA Industry Furnace MAKE Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

LF ladle refining furnace Ladle capacity100t

Equipment use:

LF ladle refining furnace can be used for refining molten steel in

primary furnaces (electric arc furnace, open hearth furnace,

converter, etc.), and is an important metallurgical equipment for

continuous casting and continuous rolling.

1. Equipment features:

LF ladle refining furnace has many functions, such as heating and

heating, fine-tuning of alloy composition, argon stirring, rapid

temperature measurement and sampling, desulfurization, removal of

impurities, feed wire adjustment, etc., so that the entire

steelmaking process can be reasonably matched and production

continuity can be improved.

Equipment composition:

1. ladle and ladle car;

2. Furnace cover and furnace cover lifting device;

3. Electrode lifting device: including trolley mobile and column

lifting, its driving mode has two kinds of motor drive and

hydraulic drive; ④ High current line: energy-saving short net,

copper steel composite conductive cross arm, water-cooled cable;

4. Electrical control system: The electrical control system adopts

a new type of frequency conversion speed regulation type or

proportional valve hydraulic regulation type, and each part of the

action and electrode regulator is controlled by PLC/DCS system; ⑥

Hydraulic system and control valve system; ⑦ Argon gas system;

5.Cooling water and its monitoring alarm system.

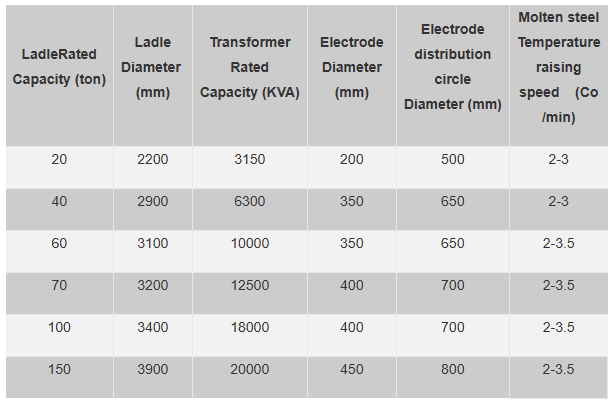

Main Technical Specifications:

About Us:

With more than 20 years of rich experience, manufacturer in the field of metallurgical machinery equipment, from design, manufacturing to marketing. We have hundreds of successful cases in designing and producing the whole set of equipment, such as Electric Arc Furnace (EAF), Ladle Refining Furnace (LF), Submerged Arc Furnace (SAF), Argon Oxygen Decarburizing Furnace (AOD), Basic Oxygen Furnace (BOF), White Fused Alumina Furnace, Brown Fused Alumina Furnace and CCM Hot Rolling Mill etc.

|