| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Reefer Semi Trailer |

|---|---|

| Use: | Truck Trailer |

| Type: | Semi-Trailer |

| Material: | FRP-Pie Modular Panel |

| Size: | 45ft |

| Max Payload: | 30 T |

| Place of Origin: | China |

| Brand Name: | G.E.T |

| Skin Material / Core Material: | FRP / PUR -Polyurethanes |

| K Value / Min. Temperature: | 0.295 W/㎡ ℃. , -32 ℃ |

| Refrigerated Trailer Application: | Frozen Meat, Ice Cream, Seafood, Fresh Vegetable, Fruits, Milk |

| Refrigerated body Technology: | German Pressure Machine Positive pressure vacuum Process |

| Refrigerated body Floor: | Forklift working available |

| Refrigerated Trailer body Portal: | Stainless Steel / 2-wings opening Hinge doors / Roll Up door |

| Trailer Axle: | Square Drum Axle brand FUWA / BPW |

| Trailer Suspension: | Mechanical Tandem / Air Spring / Bogie |

| Refrigerator Units: | Thermoking / Carrier Brand |

| Refrigerated TrailerWorking Life: | 10-15 years per the working condition |

| Certification: | CE,CCC |

| Packaging Details: | SKD OR CKD TYPE WITH CONTAINER

CBU TYPE BY DRY BULK OR ROLL-ROLL |

| Port: | QINGDAO,CHINA |

| Supply Ability: | 200 Box/Boxes per Month |

| MOQ: | 2 boxes |

| Price: | $35,000.00/boxes 2-4 boxes |

| Company Info. |

| GET INDUSTRY & VEHICLES CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

45ft 3 axles Frozen Meat FRP coating PUR Refrigeration Semi Trailer with Thermoking carrier Refrigerator Units for frozen meat fish

seafood | ||||||

1. MODEL: | GET9303XLC | |||||

This insulated/Refrigerated semi trailer made with our All-plastic

Van body panels, can equip the Thermoking or carrier refrigerator units to transport the frozen or fresh food and vegetables with temperature from -18 ℃ to 15℃. it meets all D.O.T.COC specifications. | ||||||

2. GENERAL | ||||||

Overall Length | 45 ft | 13,600 mm | ||||

Overall Width | 9 ft | 2,600 mm | ||||

Overall Height | 13 ft | 4,000 mm | ||||

Fifth Wheel Height | 4 ft | 1,200 mm | ||||

Kingpin Location | 2 ft | 700 mm | From the rear face of the front bolster | |||

Landing Gear Location | 8 ft | 2,420 mm | From the kingpin center | |||

Axle Spread | 4 ft | 1,310 mm | ||||

Tandem Location | 21 ft | 6,530 mm | From Kingpin to Front Suspension Hanger | |||

Tare Weight | 17,640 Ibm | 8,000. kg | ||||

Payload | 66,140 Ibm | 30,000. kg | ||||

3.Insulated & Refrierated Van | ||||||

K .Value for the Composite Box | 0.295 W/㎡ ℃ | |||||

MAX.BOX VOLUME: | 72.05 m³ | |||||

Overall Length | 44 ft | 13,430 mm | Exterior dimenion | |||

Overall Width | 8 ft | 2,470 mm | Exterior dimenion | |||

Overall Height | 8 ft | 2,570 mm | Exterior dimenion | |||

Floor Thinckness | 4 .13 inch | 105 mm | ||||

Side Wall Thickness | 3 .31 inch | 84 mm | ||||

Front Wall Thickness | 3 .31 inch | 84 mm | ||||

Rear Door Panel | 3 .31 inch | 84 mm | ||||

Roof Wall | 4 .13 inch | 105 mm | ||||

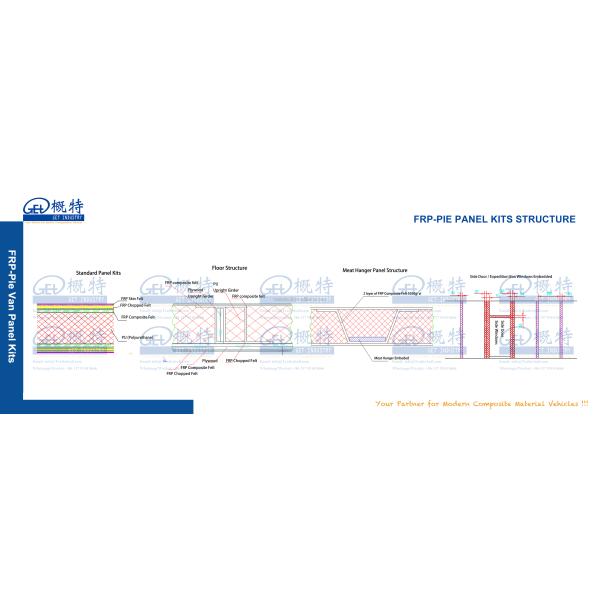

4. Box Structure | ||||||

super Structure | Self-supporting body, without cross bars , inside and outside skin

made of glassfibre reinforced polyester, reinforced with Z-straps

,the Core of hard foam with best insulation properties. Without metallic carrier elements = without direct heat conductivity The body are watertight The plastic elements are flam resistant | |||||

Rear Wall | Two-wing full open Rear door , approx ,80 mm thick with 5-fold

special sealing ,rigid frame joints. Each Door Wing with 1 external power-brace lock with one -hand operation Door Wings inclinable to the sidewalls with hold-open device (loose) | |||||

Portal | stainless Steel 304 | |||||

Surface | The Plastic elements are painted white | |||||

5. Refrigeration units | ||||||

Refrigeration units: | Thermoking Trailer Units SlXe 400-50 with standby Option: Carrier | |||||

Temperature Range | -20 ℃ -+20 ℃ | |||||

Compressor | Two split compressors: One is powered by Self installed Diese engine The second one is powered by an electric standby motor (220/1phase/50 hz) to be connected to land line | |||||

Payload | 20℃ 8200 W / 0℃ 14800 W | |||||

5. Box profiles options: | ||||||

Doors | Tri-fold rear door | |||||

Roll up rear door | ||||||

Single-open side door | ||||||

Double-open side door | ||||||

Curtains for doors | Door curtain profiles parts | |||||

Side door curtains | ||||||

Rear door curtains | ||||||

Floor profiles | M-coat floor-composite type | |||||

Alu. Checked plate floor 3mm -composite type | ||||||

Stainless steel plate floor 1.5mm -composite type | ||||||

Side air duct - alu.u channel vertical direction | ||||||

Kick plate-aluminum 300*2mm-composite type | ||||||

Aluminum Profiles | ||||||

Cargo profiles | Cargo fix track | |||||

Side door steps | ||||||

Evaporator proctor | ||||||

Evaporator proctor for trailer units | ||||||

Moveable compartment system ( box >5000mm can choose) | ||||||

Meat carcass hang system | Meat hang box design 3,4,5 lines of sliding rail | |||||

Meat hang box desig = 6 lines of sliding rail | ||||||

Meat hang rail | ||||||

Meat hooks | ||||||

STEEL STRUCTURE AND TRAILER CHASSIS SYSTEM | ||||||

Main beam | Deep: 450 mm (17.7") Auto-welt Main Beam With High strength low alloy steel with 350 MPa yield hot-rolled I-beam, ASTM A572 Grade 50 or equivalent (Q345) | |||||

Upper coupler | 1/4” pick up plate with JOST 2” diameter square type king pin per

SAE standard | |||||

Landing gear | 25T ( 55,000 lbs) capacity, 2-speed 19” travel with low “T” shoes | |||||

Suspension | Mechanical tandem suspension with leaf springs. Options: Air Spring Suspension , Bogie Suspension | |||||

Axles | 13T Drum Brake Square /Round Axle Option : Disc Type Manufacturer: FUWA ,Options: BPW,SAF | |||||

Wheels | 22.5 x 8.25 hub-piloted wheels | |||||

Tires | 11R22.5-14PR tubeless type | |||||

Brake System | Dual air brake system, WABCO/HALDEX relay emergency valve, OPTIONS:

ABS brake system | |||||

Phillips glad hand 12-0061 and 12-0081 and T30/30 stroke brake

chamber | ||||||

Electrical | OPTRONICS 12-volt LED lighting with Phillips mold seal wiring

harness, meet DOT and SAE standards. The proof design is used for

4” LED lighting. | |||||

Painting | Abrasive blast of all metal surfaces – not less than SA-2.5 to

achieve clean bare steel Surface will be coated with marine paint of minimum 70% Zinc- Rich primer and true acrylic aliphatic urethane topcoat, color optional, total thickness not less than 80μm after dry membrane | |||||

Option | Hubodometer, PSI tire inflation system | |||||

|