| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Rigid Flex PCB |

|---|---|

| MOQ: | 1 |

| Price: | Inquiry Us |

| Payment Terms: | T/T |

| Supply Ability: | 200,000+ m² PCB per Month |

| Layers: | 4 Layer |

| Board Thickness: | Rigid:2.5mm;Flex:0.26+/-0.05mm |

| Copper Thickness: | 1OZ |

| Base Material: | Polyimide+FR4 |

| Min. Line Width/Space: | 0.13/0.13mm |

| Min. hole size: | 0.12mm |

| Surface Treatment: | ENIG |

| Application: | Medical Devices |

| Service: | One Stop Turnkey Include Firmware,PCB&PCBA,OEM Services Provided |

| Company Info. |

| DQS Electronic Co., Limited |

| Verified Supplier |

| View Contact Details |

| Product List |

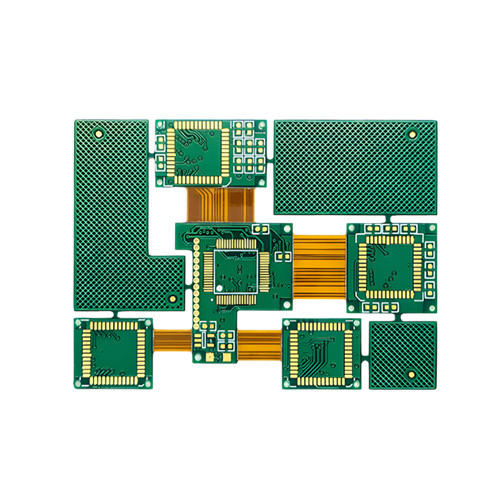

High Reliability Rigid-Flex PCB Communications Equipment Bending Resistance PCB Manufacture

♦ What is Rigid-Flex PCB?

Rigid-Flex PCB is a composite structure circuit board that combines a rigid printed circuit board (PCB) and a flexible circuit board (FPC). It is mainly composed of two parts: rigid and flexible. The rigid layer is made of traditional PCB materials (such as FR-4), providing stable electrical performance and mechanical strength; the flexible layer is made of flexible circuit materials such as polyimide or polyester, which has high bending and folding resistance; the two are connected by special adhesives or welding processes.

♦ Features of Rigid-Flex PCB

Efficient wiring: High-density multi-layer design to meet the needs of complex circuits.

Widely used: Covering aerospace, medical, automotive, consumer electronics and other fields.

Reduce failures: Reduce welding points and cable connection problems, improve product stability.

Strong impact resistance: Resistant to high stress, suitable for harsh scenarios such as vibration and collision.

♦ Applications of Rigid-Flex PCB

♦ Technical Parameters

|