| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Fin Tube |

|---|---|

| Brand Name: | YUHONG |

| Model Number: | HELICAL SERRATED FIN TUBE |

| Certification: | ABS, GL, DNV, NK, PED, AD2000, GOST9941-81, CCS, ISO 9001-2008 |

| Place of Origin: | CHINA |

| MOQ: | 1PC |

| Price: | Negotiable |

| Payment Terms: | L/C at sight, T/T |

| Supply Ability: | 10000 PCS PER MONTH |

| Delivery Time: | Depending on QTY |

| Packaging Details: | Iron frame case |

| Product name: | HELICAL SERRATED FIN TUBE |

| Base tube materical: | A312 TP347 or other kind of material |

| Processing method: | Welding |

| Tube Size: | 16-219 mm |

| Fin Height: | 5-30 mm |

| Fin Pitch: | 3-25 mm |

| High Light: | SERRATED FIN TUBE / HFW |

| Application: | Boiler economizer / Air preheater / Waste heat boiler |

| Company Info. |

| Yuhong Group Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

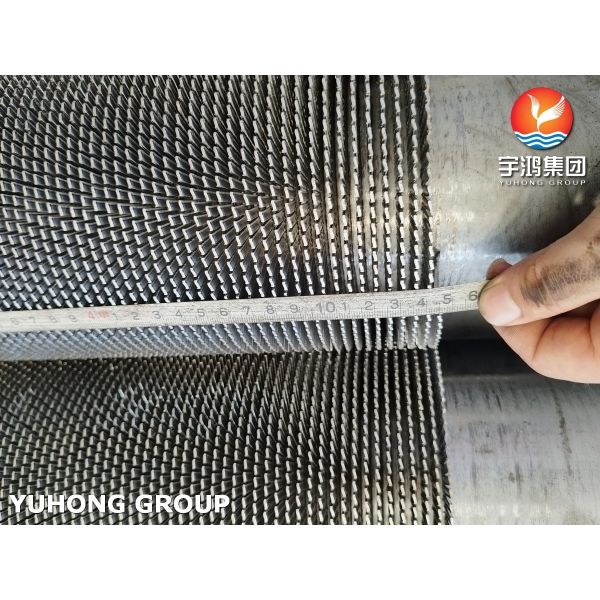

A312 TP347 Stainless Steel Helical Serrated HFW Fin Tube

The A312 TP347 Stainless Steel Helical Serrated HFW (High-Frequency Welded) Fin Tube is a high-performance heat transfer solution designed for industrial applications requiring superior corrosion resistance, high-temperature strength, and efficient heat transfer.

Key Features

Material:

Made from TP347 stainless steel, a stabilized austenitic stainless steel containing niobium for

enhanced resistance to intergranular corrosion and excellent

high-temperature oxidation resistance.

Helical Serrated Design:

The helical serrated fins are precision-engineered to maximize surface area, resulting in

improved heat transfer efficiency. The serrated design also

enhances airflow and reduces fouling, ensuring long-term

performance.

HFW (High-Frequency Welded) Technology:

The fins are high-frequency welded to the base tube, providing a strong mechanical bond and excellent

thermal conductivity. This ensures durability and resistance to

thermal cycling.

Corrosion and High-Temperature Resistance:

TP347 stainless steel offers outstanding resistance to oxidation,

sulfidation, and other forms of corrosion in high-temperature

environments, making it suitable for demanding applications.

A312 TP347 Chemical Composition

GRADES | UNS | C | Mn | P | S | Si | Cr | Ni |

|---|---|---|---|---|---|---|---|---|

TP347 | S3470 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-13.0 |

A312 TP347 Mechanical Properties

Material | Heat | Temperure | Tensile Strength | Yield Strength | Elongation %, Min |

TP347 | Solution | 1900 (1040) | 75(515) | 30(205) | 35 |

Application

Advantages

|