316H Stainless Steel Plates: Engineering Excellence for Extreme

Environments

316H stainless steel plates represent a specialized subset of

austenitic stainless steels, designed to thrive in applications

where high temperatures, corrosive chemicals, and structural

integrity converge. Unlike generic stainless steel plates, 316H

plates are tailored with a unique chemical composition that

amplifies both high-temperature strength and corrosion resistance,

making them indispensable in industries ranging from petrochemicals

to power generation. This detailed overview explores their

composition, manufacturing nuances, performance attributes, and

real-world applications, highlighting what sets them apart from

standard 316 plates and other alloys.

At the core of 316H plates’ durability is their precise alloy

makeup, which builds on the proven chemistry of 316 but with a

critical modification: carbon content. While standard 316 stainless

steel limits carbon to 0.08% maximum, 316H increases this range to

0.04–0.10%. This intentional boost serves a vital purpose: carbon

strengthens the material’s grain boundaries, preventing creep

(slow, permanent deformation under sustained stress) when exposed

to high temperatures— a common failure mode in industrial equipment

operating above 600°C (1112°F).

Beyond carbon, 316H plates retain the alloying elements that make

316 a staple in corrosive environments:

- Chromium (16.0–18.0%): Forms a passive oxide layer on the plate’s surface, shielding it

from oxidation and general corrosion. This layer self-heals if

scratched, ensuring long-term protection.

- Nickel (10.0–14.0%): Stabilizes the austenitic crystal structure, which grants 316H

its exceptional ductility and toughness, even at low temperatures.

This property is crucial for forming plates into complex shapes

without cracking.

- Molybdenum (2.0–3.0%): A defining element that elevates 316H above chromium-nickel

steels like 304. Molybdenum enhances resistance to pitting and

crevice corrosion, particularly in chloride-rich environments—think

seawater, brines, or chemical processing fluids.

- Trace elements, including manganese (2.0% max), silicon (0.75%

max), and phosphorus (0.045% max), further refine mechanical

properties, balancing formability with strength.

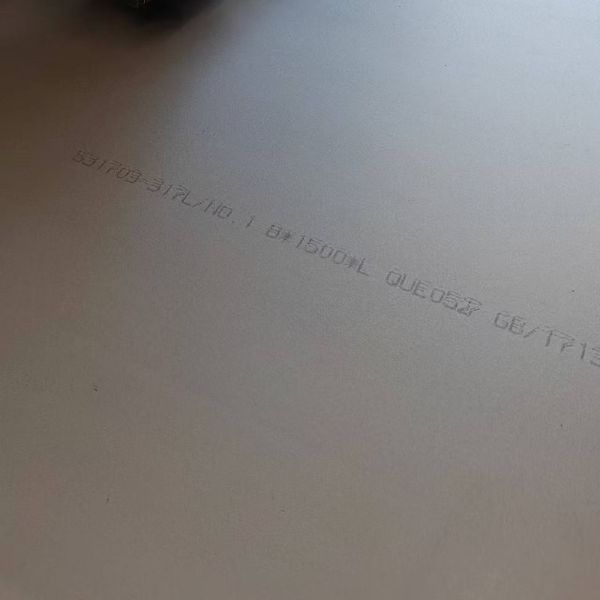

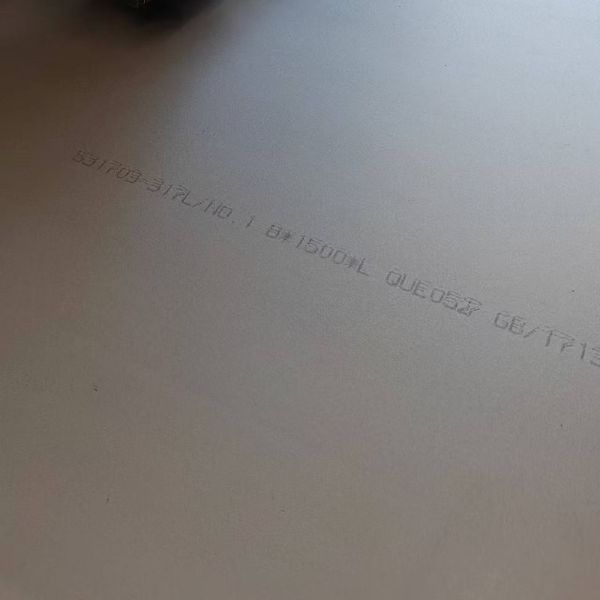

316H stainless steel plates are produced through a rigorous process

to ensure uniformity and performance. The journey begins with

melting high-purity raw materials in electric arc furnaces,

followed by refining to remove impurities like sulfur and oxygen.

Once the alloy reaches the desired composition, it undergoes hot

rolling—passing through rollers at temperatures exceeding 1100°C

(2012°F)—to form plates of varying thicknesses, typically ranging

from 1.5mm to 150mm, though custom sizes are available for

specialized projects.

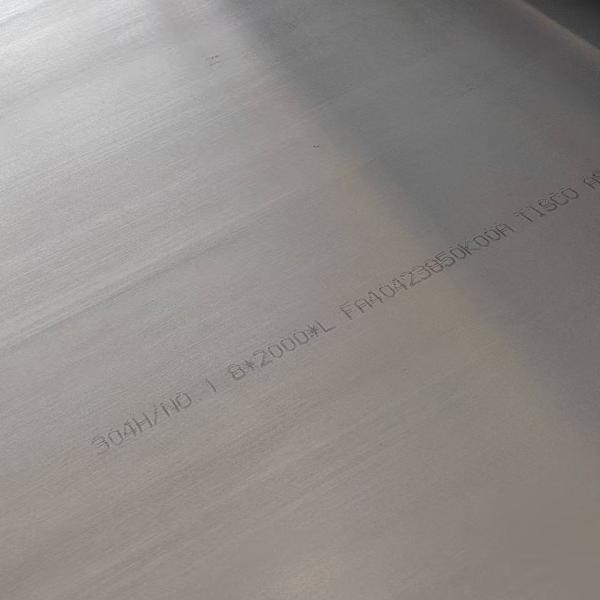

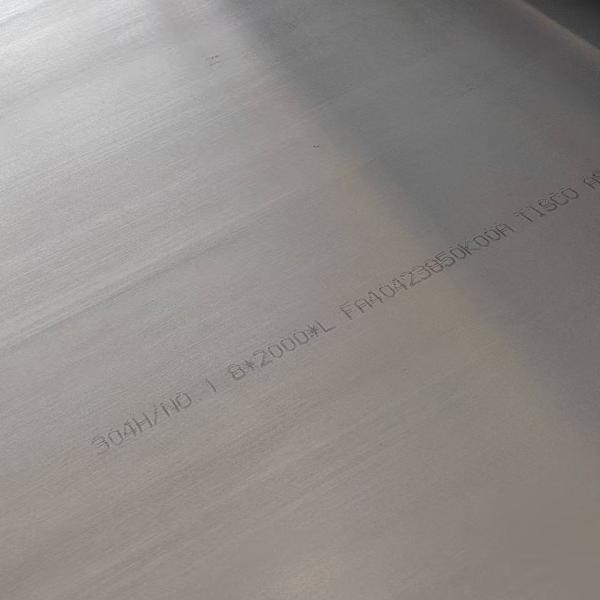

Cold rolling may be employed for thinner plates (below 3mm) to

achieve tighter dimensional tolerances and a smoother surface

finish, critical for applications where hygiene or fluid flow

efficiency matters, such as in food processing or pharmaceutical

equipment. Post-rolling, plates undergo annealing—a heat treatment

process where they are heated to 1050–1150°C (1922–2102°F) and

rapidly cooled—to restore ductility and dissolve any harmful

precipitates that could weaken the material.

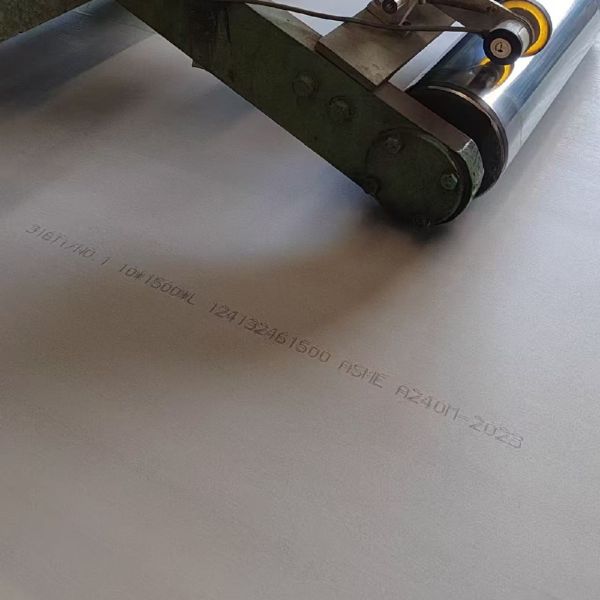

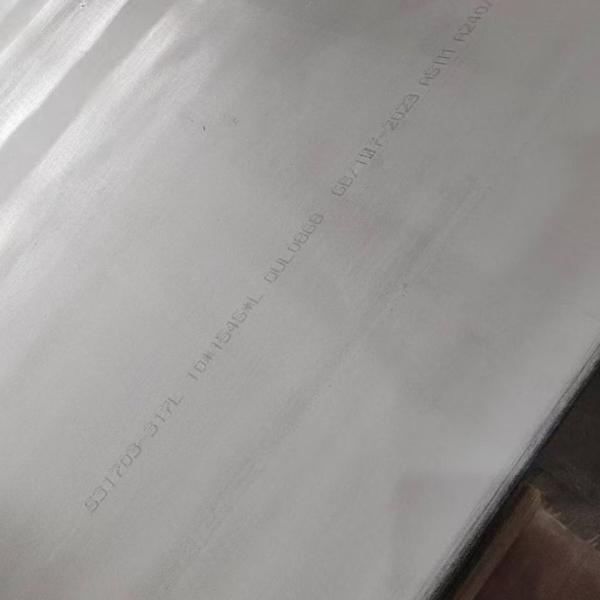

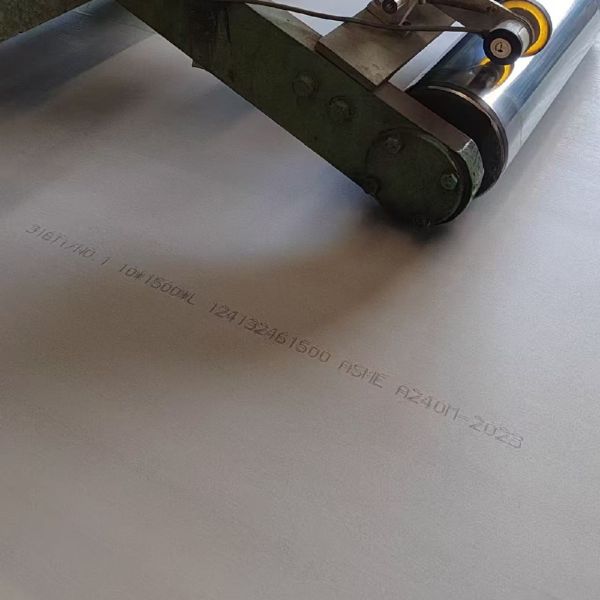

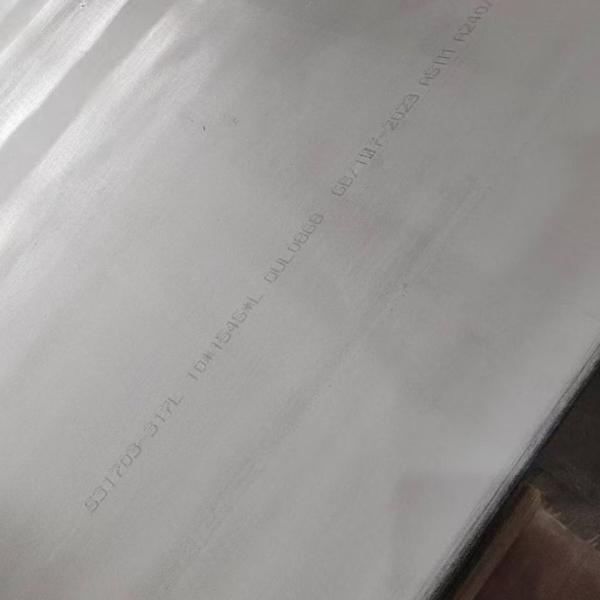

What distinguishes 316H plate manufacturing from standard 316 is

the strict control over carbon distribution. During annealing,

precise temperature regulation ensures carbon remains evenly

dispersed within the austenitic matrix, avoiding grain boundary

carbide precipitation that could compromise corrosion resistance.

This attention to detail makes 316H plates particularly reliable in

welded structures, where heat-affected zones (HAZs) are prone to

weakness.

316H plates excel in mechanical properties that matter for

structural applications. Their minimum tensile strength of 515 MPa

and yield strength of 205 MPa ensure they can withstand heavy

loads, while an elongation of 40% (minimum) allows for bending,

forming, and fabrication without fracturing. This combination of

strength and ductility makes them suitable for everything from

pressure vessels to structural supports in offshore platforms.

Where 316H plates truly stand out, however, is in their thermal

performance. Unlike standard 316, which may exhibit creep at

temperatures above 650°C (1202°F), 316H plates maintain structural

integrity up to 800°C (1472°F). Creep resistance is critical in

applications like boiler tubes, furnace liners, and turbine

components, where materials are subjected to constant stress at

high temperatures over years of operation. Tests show that 316H

plates experience less than 0.1% creep deformation after 10,000

hours at 700°C (1292°F) under a stress of 100 MPa—far outperforming

many other austenitic steels.

Thermal conductivity is another key attribute: 316H plates conduct

heat at a rate of 16.2 W/(m·K) at 100°C (212°F), making them

effective in heat exchangers where controlled thermal transfer is

essential. They also exhibit low thermal expansion (16.0 × 10⁻⁶/°C

between 0–100°C), reducing the risk of warping or cracking when

exposed to rapid temperature fluctuations—a common challenge in

industrial furnaces.

Corrosion resistance is the cornerstone of 316H plates’ appeal,

especially in aggressive environments. Their molybdenum content

makes them highly resistant to chloride-induced pitting—a form of

localized corrosion that can cause sudden failure in unprotected

metals. In salt spray tests, 316H plates show no signs of pitting

after 5,000 hours of exposure, compared to 304 plates, which may

exhibit pitting within 1,000 hours. This makes them ideal for

marine applications, such as ship hulls, propeller shafts, and

coastal infrastructure, where seawater immersion is constant.

They also resist corrosion in acidic and alkaline environments. In

sulfuric acid solutions (up to 5% concentration at 60°C/140°F),

316H plates corrode at a rate of less than 0.1 mm/year—slow enough

to ensure decades of service in chemical processing tanks and

pipelines. Similarly, in caustic soda (sodium hydroxide) solutions,

they outperform carbon steels, which corrode rapidly, and even some

nickel alloys, which can become brittle under prolonged exposure.

A unique advantage of 316H plates is their resistance to

intergranular corrosion (IGC), a type of degradation that attacks

grain boundaries. Thanks to their controlled carbon content and

annealing process, they pass the ASTM A262 Practice E test—a

rigorous standard for evaluating IGC resistance—making them safe

for use in high-purity applications like pharmaceutical reactors

and food processing equipment, where metal contamination could

compromise product quality.

316H stainless steel plates are the material of choice in

industries where failure is not an option. In the petrochemical sector, they line reactor vessels and transfer pipelines handling crude

oil, natural gas, and corrosive byproducts. Their ability to

withstand high pressures (up to 10,000 psi) and temperatures

(600–800°C) makes them indispensable in hydrocracking units, where

heavy hydrocarbons are broken down into lighter fuels.

In power generation, 316H plates form the heat exchanger tubes and boiler panels of

coal-fired, gas-fired, and nuclear power plants. Here, they endure

continuous exposure to superheated steam (up to 550°C/1022°F) and

combustion byproducts, including sulfur dioxide, without succumbing

to corrosion or creep.

The marine industry relies on 316H plates for offshore platforms, where they resist

saltwater, wave impact, and biofouling. They are also used in

desalination plants, where seawater is converted to freshwater—an

environment rich in chlorides that would quickly degrade lesser

materials.

Other applications include aerospace components (jet engine exhaust liners), industrial furnaces (retorts and heating elements), and pollution control equipment (scrubbers that remove acidic gases from industrial emissions). In

each case, 316H plates deliver a rare combination of strength,

longevity, and reliability that reduces maintenance costs and

extends equipment lifespans.