| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Sinotruk Howo Parts |

|---|---|

| Brand Name: | ORIGINAL |

| Model Number: | AZ9725520278 |

| Certification: | ISO9001 |

| Place of Origin: | CHINA |

| MOQ: | 15 PCS |

| Price: | USD40 2PCS USD39 20PCS USD38 200PCS |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 2PCS 2 DAYS 20PCS 5DAYS 200PCS 7DAYS |

| Packaging Details: | carton |

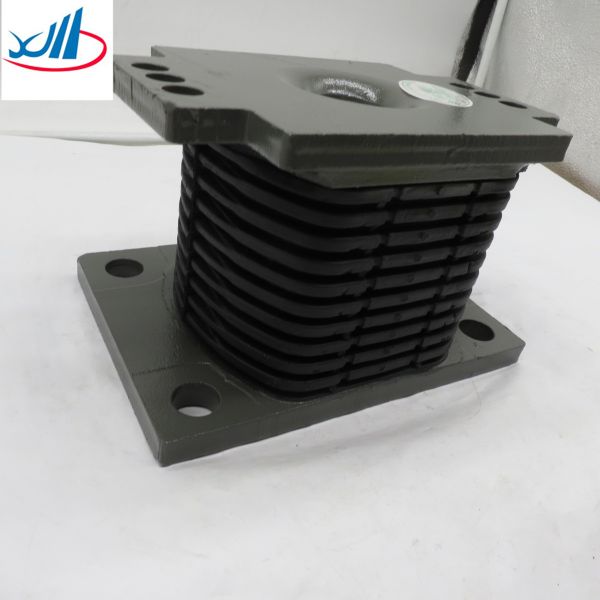

| NAME: | good performance Rubber bracket AZ9725520278 |

| OEM NUMBER: | AZ9725520278 |

| SIZE: | 3*3*5 |

| weight: | 0.1KG |

| packing: | CARTON |

| PAY: | alibaba |

| TIME: | 1-13 DAYS |

| mode of transport: | air car |

| material: | iron |

| MOQ: | 15 |

Rubber Bearer Seat Support Sinotruk Howo Spare Parts AZ9725520278

| Vehicle type | Building loader | Certification | ISO9001 |

Warranty period | 1 year | Delivery time | 4 DAYS |

Quality | Original | Material | Iron |

| Name | Rubber Bearer Seat Support Sinotruk Howo Spare Parts AZ9725520278 | Oem | |

| Sea | Qingdao | Packing | Carton |

| Working principle | Rubber bearing is a common structural support material, its working principle is to absorb and disperse the load of the structure through the elastic deformation of rubber, so as to protect the structure from damage. The main components of the rubber bearing are the rubber pad and the metal plate, of which the rubber pad is a key part of the support and buffer. The material of rubber pads is usually high-strength rubber, which has good elasticity and durability and can withstand a large number of loads and deformation. When the structure is subjected to load, the rubber pad will undergo elastic deformation, so as to absorb and disperse the load and reduce the deformation and vibration of the structure. At the same time, the elastic deformation of the rubber pad can also adapt to the deformation of the structure to ensure the stability and safety of the structure. The working principle of the rubber bearing also involves the role of the metal plate. Metal plates are usually used to fix rubber pads and connecting structures, and their materials are usually high-strength steel plates that can withstand a large amount of weight |

| The role of rubber bearings for vehicles | Vehicle rubber bearing is a common shock absorption and noise

reduction material, its main role is to reduce the vibration and

noise generated by the vehicle through the road or bridge, improve

the stability and comfort of driving. At the same time, the vehicle

rubber bearing can also prevent the structural damage of the bridge

or tunnel caused by the turbulence of the vehicle, and ensure the

safety of traffic construction facilities. Second, the use of rubber bearings for vehicles 1. Transportation construction Rubber bearings for vehicles are widely used in road, railway, bridge, tunnel and other traffic construction fields. In road construction, rubber bearings are mainly used in the connection of expressways, urban expressways, viaducts, Bridges, tunnels, etc., to reduce the impact and noise pollution caused by vehicles when driving on the road surface; In railway construction, rubber bearings are mainly used in rail seats and support systems of high-speed railways, subways, light rail, etc., to ensure the smooth and safe running of trains. |

In the process of using automotive rubber bearings, the following

points need to be noted:

1. The selection of rubber bearings should be selected according to

the actual use conditions and needs, and different types of

bearings are suitable for different working environments.

2. The rubber bearing should pay attention to the correct fitting

and fixing during the installation process to ensure the firm and

stable support.

3. Regularly check and maintain the status of rubber bearings, and

timely replace aging or damaged supports.

【 Conclusion 】

As a common shock-absorbing and noise-reducing material, automotive

rubber bearing has a wide range of applications in traffic

construction and industry, which can effectively reduce the

interference and damage to the surrounding environment when the

vehicle is running, and improve the smoothness and comfort of the

driving. In the process of using automotive rubber bearings, it is

necessary to pay attention to the selection of the appropriate

support model, correct installation and fixing, and regular

inspection and maintenance of the state of the support.

|