| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Planetary Ball Mill |

|---|---|

| Brand Name: | TENCAN |

| Model Number: | XQM-10 |

| Certification: | CE ISO |

| Place of Origin: | Hunan, China |

| MOQ: | One set |

| Price: | Negotiable |

| Payment Terms: | T/T, Western Union, L/C, MoneyGram, |

| Supply Ability: | 200 sets per month |

| Delivery Time: | 3-7 working days after receive full payment |

| Packaging Details: | Carton or Plywood Case |

| Product Name: | Lab square Planetary Ball Mill |

| Model No.: | XQM-10 |

| Voltage: | 220V-50Hz or 110V-60Hz |

| Power: | 1.5kW |

| Rotate Speed: | 70-580 RPM |

| Speed Control: | Frequency Control |

| Total Volume: | 10L |

| Max Capacity: | 3.5L |

| Company Info. |

| Changsha Tianchuang Powder Technology Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

⇒

⇒

Before Grinding After Grinding

Features:

1. The stable speed of gear transmission ensures the consistency

and repeatability of the experiment.

2. The machine adopts the principle of planetary motion, with fast

speed, high energy, high efficiency, and small particle size.

3. Four different sizes and materials of powder samples can be

produced at once.

4. The machine is controlled by a frequency converter, and you can

choose the ideal speed based on the expected experimental results.

The frequency converter is equipped with undervoltage and

overcurrent devices to protect the motor.

5. The planetary ball mill has the functions of timed power-off,

self timed forward and reverse rotation. You can freely choose any

operation mode such as one-way, alternating, continuous, time

setting, etc. according to the experimental needs to improve

grinding efficiency.

6. Technical characteristics of Tencan ball mill: low center of

gravity, stable performance, compact structure, easy operation,

safe and reliable, low noise, and low loss.

7. A safety switch is installed on the machine to prevent safety

accidents when the safety cover is opened during operation.

Technical Features

| Technical Features | |

| Drive Mode | Gear drive and belt drive |

| Operate Mode | Two or four grinding tanks working together |

| Maximum Loading Capacity | 2/3 of the capacity of milling tank |

| Feeding Size | < 10mm for soft material; < 3mm for hard material |

| Output Granularity | Minimum 0.1μm |

| Rotational Speed Ratio | 1/2 |

| Max.Continuous Operating Time | 72 hours |

| Materials of Jar | stainless steel,agate,nylon,corundum,zirconia, PU, PTFE etc |

Technical Parameters

| Main Parameters of 8L 110 / 220v Planetary Ball Mill - Square design | |||||

| Model | Power(kW) | Voltage | Dimension(mm) | Revolution Speed (rpm) | Rotation Speed (rpm) |

| XQM-8 | 1.5 | 220V-50Hz | 900*600*640 | 35-290 | 70-580 |

| XQM-10 | 1.5 | 220V-50Hz | 900*600*640 | 35-290 | 70-580 |

| XQM-12 | 1.5 | 220V-50Hz | 900*600*640 | 35-290 | 70-580 |

Accessories of Mill Jars & Balls

Available Mill Jars:

304 stainless steel mill jar, 316 stainless steel mill jar, tungsten carbide mill jar, agate mill jar, alumina ceramic mill jar(also called corundum mill jar), zirconia mill jar, nylon mill jar, polyurethane mill jar, mill jar (PTFE), and etc.

| Recommendation For Matching Solutions About Mill Jars & Materials | |

| Categories of Materials | Recommended Mill Jars |

| Soil and other Materials which are not allowed with any impurity | Agate mill jar |

| Metal & nonmetal materials which are not allowed with any impurity | Zirconia mill jar |

| High hardness materials like diamond, tungsten carbide | Tungsten carbide mill jar |

| Strong add & alkali materials or other materials at high temperature | PTFE mill jar |

| Iron ore materials with lower impurity sensitivity | 304 Stainless steel mill jar |

| Pigment or other materials with later process under high temperature | Nylon mill jar |

| Aluminum materials like ceramic glaze | Corundum mill jar |

| Electronic materials like lithium battery | Polyurethane mill jar |

| Easily oxidized materials or some special materials which need to be protected under special atmosphere. | Vacuum mill jar |

| References for Matchable Jar Sizes with Squre type Planetary Ball Mill | ||||

| Model No. | Total Volume (L) | Matchable Jar Sizes | Matchable Jars Quantity | Matchable Vacuum Jar Sizes |

| XQM-1 | 1.0L | 50ml, 100ml, 250ml | 2pcs or 4pcs | 50ml, 100ml |

| XQM-2 | 2.0L | 250ml, 500ml | 2pcs or 4pcs | 50ml, 100ml, 250ml |

| XQM-4 | 4.0L | 250ml, 500ml,1000ml | 2pcs or 4pcs | 50ml, 100ml, 250ml, 500ml |

| XQM-6 | 6.0L | 500ml, 1000ml, 1500ml | 2pcs or 4pcs | 50ml, 100ml, 250ml, 500ml, 1L |

| XQM-8 | 8.0L | 1L, 2L | 2pcs or 4pcs | 50ml, 100ml, 250ml, 500ml, 1L, 1.5L |

| XQM-10 | 10.0L | 1L, 2L, 2.5L | 2pcs or 4pcs | 1L, 1.5L, 2L |

| XQM-12 | 12.0L | 1L, 2L, 2.5L, 3L | 2pcs or 4pcs | 1L, 1.5L, 2L |

| XQM-16 | 16.0L | 2L, 3L, 4L | 2pcs or 4pcs | 1L, 1.5L, 2L, 3L |

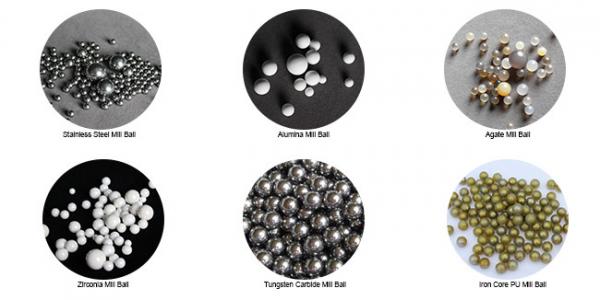

Available Mill Balls:

304 stainless steel mill balls, 316 stainless steel mill balls, tungsten carbide mill balls, agate mill balls, alumina balls, zirconia mill balls, and etc.

| References About Grinding Medias & Materials | ||

| Materials of Grinding Media | Hardness (Mohs) | Features |

| Zirconia Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high temperature resistance. |

| Stainless Steel Balls | ≥6.0 | Wear-resistant, general corrsion resistance, high temperature resistance. |

| Agate Balls | ≥7.0 | Super wear-resistance, used for medicine,food and other materials which can not be contaminated with metal, corrosion, and high temperature resistance. |

| Alumina Balls | ≥8.5 | Wear-resistant, corrsion resistance and high temperature resistance. |

| Tungsten Carbide Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high temperature resistance. |

| Matching Solutions for Mill Jars & Balls | |||||

| Items | Agate Balls | Alumina Balls | Stainless Steel Balls | Zirconia Balls | Tungsten Carbide Balls |

| Agate Mill jar | √ | ||||

| Corundum Mill Jar | ▲ | √ | ▲ | ||

| Stainless Steel Mill Jar | √ | ||||

| Zirconia Mill Jar | ▲ | √ | |||

| Nylon Mill Jar | ▲ | √ | |||

| PTFE Mill Jar | √ | ▲ | |||

| Polyurethane Mill Jar | √ | ▲ | |||

| Tungsten Carbide Mill Jar | ▲ | √ | |||

| √ means: most suitable ▲ means: suitable | |||||

|