| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Stationary Spot Welding Machine |

|---|---|

| Brand Name: | Xingweihan |

| Model Number: | D(N)B--100,D(N)B--160, D(N)B--200, D(N)B--250 |

| Certification: | CE, RoHs |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | USD20000-USD25000 |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Supply Ability: | 50 sets/month |

| Delivery Time: | 30 working days |

| Packaging Details: | Wooden Case |

| Product name: | Stationary Type Aluminum Sheet Metal Pneumatic Automatic Resistance Spot Welder Projection Welding Machine Price For Ss Sheet |

| Application: | Sheet Metal Industries |

| Function: | Nut Welding Machine |

| Machine type: | Medium Frequency Spot Welding Machine |

| Keyword: | Bolt Spot Welding Machine |

| Welding Material: | Alloy Metal Aluminum Stainless Steel |

| Feature: | High Working Efficiency |

| Warranty: | 12 months Guarantee |

| After Warranty Service: | Video technical support, Online support and Spare parts |

| After-sales Service Provided: | Free spare parts, Field installation, commissioning and training |

| Company Info. |

| Chengdu Xingweihan Welding Equipment Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

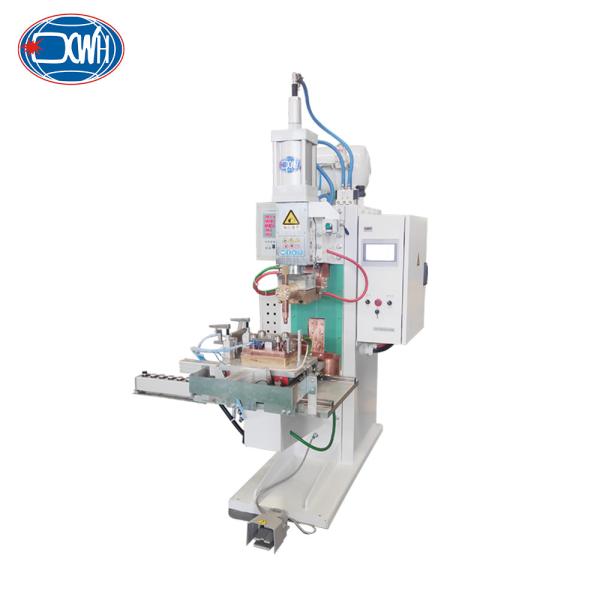

Stainless Steel Automatic Resistance Projection Welder Bolt Spot

Welding Machine

Product Introduction:

In the fields of automobile manufacturing, electronic assembly, etc., the automatic point projection welding machine for screws has become the core equipment for fastener welding. It achieves seamless connection between screws and workpieces through precise alignment and high-speed welding. The equipment has leak proof and error proof welding functions, compatible with materials such as stainless steel and carbon steel, and is particularly suitable for high cycle production lines, helping enterprises achieve intelligent upgrades.

Features:

Technical Parameters:

| Items Models | DN(B)-100 | DN(B)-160 | DN(B)-200 | DN(B)-250 |

| Rated power (KVA) | 100 | 160 | 200 | 250 |

| Power input(V) | 3φAC 380V | 3φAC 380V | 3φAC 380V | 3φAC 380V |

| Max. short circuit current (KA) | 30 | 35 | 40 | 45 |

| Duty cycle(%) | 50 | 50 | 50 | 50 |

| Max. force(N) | 6000 | 6000 | 10000 | 15000 |

| Electrode length( MM) | 450 | 450 | 450 | 500 |

| Working stroke( MM) | 80 | 80 | 80 | 80 |

| Cooling consumption(L/min) | 20 | 20 | 20 | 20 |

| Max. welding capacity(MM) | 3.0+3.0 | 4.0+4.0 | 5.0+5.0 | 6.0+6.0 |

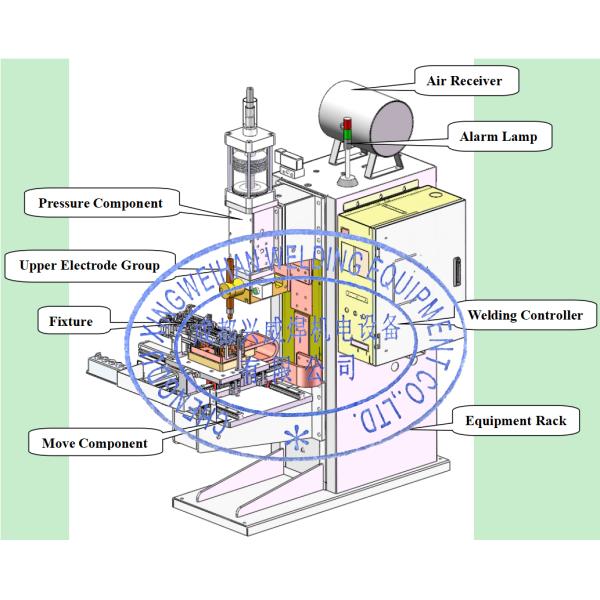

General Structures:

Detailed Images:

Customized Fixtures and Moving Components: The section mainly consists of fixtures and moving components. Manually replacing fixtures can achieve welding of two different workpieces. During welding, the workpiece can move back, forth, left, and right on the moving component. Each type of workpiece is completed in four stages, with the first three stages being projection welding and the fourth stage being spot welding.

Cylinder: Adopting aluminum alloy cylinder barrel, low damping sealing ring, and light friction ring combination with hydraulic cylinder, the surface is wear-resistant and has a long service life, achieving extremely high dot speed, electrode pressurization, smooth and fast.

Gas Storage Tanks: The projection and spot welding machine is equipped with a dedicated gas storage tank, which is beneficial for reducing welding pressure fluctuations and ensuring stable welding force.

Waterway Components: All waterway components undergo surface treatment to prevent rusting, and waterway drainage is independently discharged to the water tank. Based on the outflow situation, blockages in the waterway can be observed and eliminated.

Scene Images:

Application:

FAQ:

|