| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Stainless Steel Plate |

|---|---|

| Brand Name: | TISCO BAOSTEEL |

| Model Number: | 304H / S30409 |

| Certification: | ISO |

| Place of Origin: | China |

| MOQ: | 500 kgs |

| Price: | 1700- 2000 USD/Ton |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 20Ton per week |

| Delivery Time: | 5 - 12 days based on the quantity |

| Packaging Details: | standard packing for export |

| Products: | Stainless Steel Plate |

| Grade: | 304H / S30409 |

| Thickness: | 3.0 - 80.0mm |

| Width: | 1500mm 1800mm 2000mm |

| Surface: | NO.1 |

| Brand: | BAOSTEEL TISCO |

| Standard: | ASTM A240/240M |

| Loading Port: | Shanghai Port |

| Company Info. |

| JIANGSU MITTEL STEEL INDUSTRIAL LIMITED |

| Verified Supplier |

| View Contact Details |

| Product List |

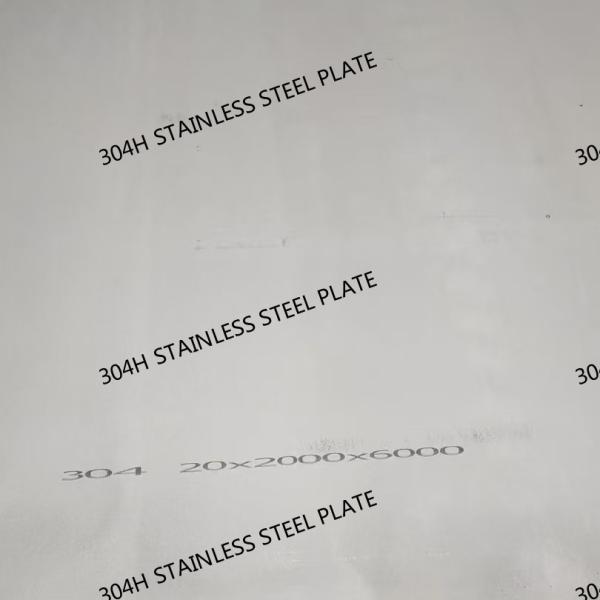

304H SS Plate High Strength Heat-Resistant Stainless Steel Thickness 1/8" to 2" Annealed Finish

Products Specification

| Products Name | 304H Stainless Steel Plate |

| Main Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316TI, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,253MA,2205,2507.etc |

| Thickness | 3.0 - 80.0mm |

| Width | 1250mm,1500mm ,1800mm,2000mm, or custom other size as request |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Type of Material | Laser Cutting |

| Form | Plate / coil |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Brand | TISCO, LISCO,BAOSTEEL , POSCO, JISCO |

1. Material Grade:

304H Stainless Steel (UNS S30409, ASTM A240/A240M, ASME SA-240)

2. Overview:

304H is a high-carbon variation of the classic 304 austenitic

stainless steel, specifically designed for enhanced strength and

creep resistance at elevated temperatures (typically above 500°C /

932°F). The "H" denotes higher carbon content (0.04–0.10%), which

stabilizes the structure against sensitization and ensures superior

performance in high-heat applications like pressure vessels,

boilers, and heat exchangers. It retains excellent corrosion

resistance, formability, and weldability.

3. Key Features & Benefits:

High-Temperature Strength: Optimized for sustained service up to 815°C (1500°F).

Creep Resistance: Minimizes deformation under mechanical stress at elevated temperatures.

Corrosion Resistance: Resists oxidation, scaling, and general corrosion in acidic/caustic environments.

Austenitic Structure: Non-magnetic, ductile, and easy to fabricate/weld.

H-Grade Compliance: Meets ASME Boiler and Pressure Vessel Code requirements for high-temperature use.

4. Chemical Composition (Typical % Weight):

| Element | Carbon (C) | Chromium (Cr) | Nickel (Ni) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | Iron (Fe) |

|---|---|---|---|---|---|---|---|---|

| Content | 0.04–0.10 | 18.0–20.0 | 8.0–10.5 | ≤2.0 | ≤0.75 | ≤0.045 | ≤0.030 | Balance |

5. Mechanical Properties (Room Temperature):

Tensile Strength: ≥515 MPa (75 ksi)

Yield Strength (0.2% Offset): ≥205 MPa (30 ksi)

Elongation: ≥40% (in 50mm)

Hardness (Brinell): ≤201 HB

Density: 8.0 g/cm³

6. High-Temperature Performance:

Max Continuous Service Temp: 870°C (1600°F)

Max Intermittent Service Temp: 925°C (1700°F)

7. Available Forms & Dimensions:

Thickness: 3mm – 100mm (Custom sizes available)

Width: 1000mm, 1219mm (48"), 1500mm, 2000mm (Custom widths)

Length: 2000mm, 2438mm (96"), 3000mm, 6000mm (Custom lengths)

Form: Hot-Rolled (HR) or Cold-Rolled (CR) Plates

8. Surface Finishes:

Hot-Rolled: No.1, Scale-Free Annealed

Cold-Rolled: 2B (Standard Bright), BA (Mirror Bright), No.4 (Brushed), HL (Hairline)

Special: Pickled, Passivated, Sandblasted

9. Standards & Certifications:

ASTM A240/A240M, ASME SA-240

EN 10028-7: X6CrNi18-10

ISO 9445, JIS G4304

Material Test Certificates (MTC) per EN 10204 3.1/3.2

10. Applications:

Boiler & Pressure Vessel Components

Heat Exchangers & Condensers

High-Temperature Pipelines & Valves

Power Generation Systems (Gas Turbines)

Chemical Processing Equipment

Furnace Parts & Heat Treatment Fixtures

11. Fabrication Notes:

Welding: Use 308H or 347 filler metal; pre/post-weld heat treatment not typically required.

Machining: Low work-hardening rate allows good machinability (use sharp tools + coolants).

Forming: Excellent ductility supports bending, stamping, and deep drawing.

12. Packaging:

Wooden crates/pallets with waterproof wrapping.

Edge protectors and anti-rust paper for corrosion prevention.

Ideal for critical applications demanding heat resistance + corrosion protection, 304H delivers unmatched reliability in extreme conditions. Its controlled carbon content prevents carbide precipitation during welding/heat exposure, ensuring long-term structural integrity.

Customization Options:

Precision cutting (waterjet, laser, plasma)

Beveled edges for welding

Non-standard dimensions & finishes

Contact us for quotes, technical specs, or material certifications!

|