| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Stainless Steel Bar |

|---|---|

| Brand Name: | Delta |

| Model Number: | 1.4418 / S135 / F6NM / 0Cr13Ni5Mo / S41500 |

| Certification: | ISO 9001 |

| Place of Origin: | China |

| MOQ: | 500 kgs |

| Price: | 2500-3200 USD/Ton |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 50 Ton per Month |

| Delivery Time: | 5 - 10 days |

| Packaging Details: | wooden box or water resistant paper surround |

| Products Name: | 1.4418 Stainless Steel bar |

| Diameter: | 10 - 350mm |

| Length: | 6m or cutting any length as request |

| Surface: | Pickling or Bright |

| Service: | Cutting |

| Standard: | ASTM DIN GB EN |

| Other products: | round bar, square bar, flat bar.etc |

| Technique: | hot rolled |

| Company Info. |

| JIANGSU MITTEL STEEL INDUSTRIAL LIMITED |

| Verified Supplier |

| View Contact Details |

| Product List |

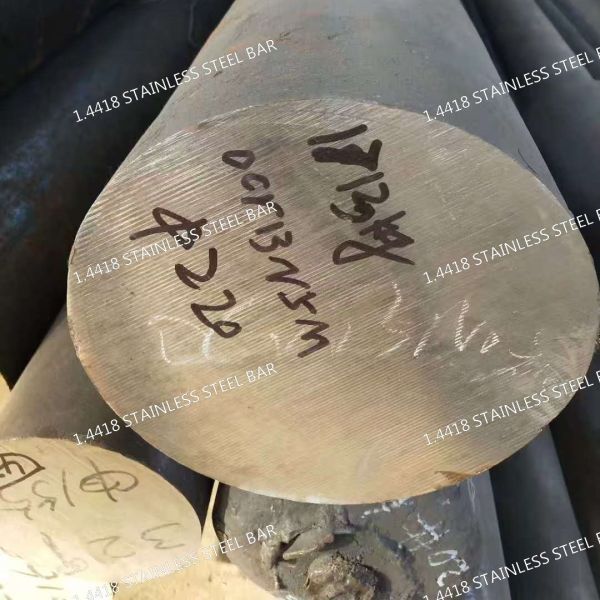

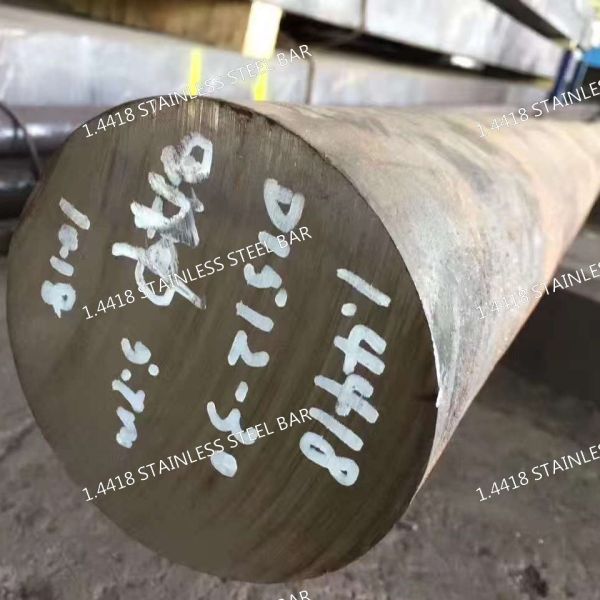

Hot Rolled S41500 Stainless Steel Rod Precision Cut 1.4418 Stainless Steel Bar Custom Sizes Available

Products Specification

| Products Name | Stainless Steel Round Bar |

| Grade | 1.4418 / S135 / F6NM / 0Cr13Ni5Mo / S41500 |

| Products Diameter Range | φ10mm - φ350mm |

| Length | 6.1m/pcs or cutting any length as request |

| Surface | Pickling finishing, bright finishing |

| Other Grade | 304,304L,309S,310S,310H,316L,316Ti,316H,317L,321,329,347,410,415,420, 430F,431,440A/B/C,2205,2507,904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,C276,600,601,625,718,800,800H,825,926.etc |

| Standard | ASTM JIS,GB,DIN EN |

| Service | Cutting |

| Other Shape | Square , Flat, Hexagonal, Round.etc |

| Loading Port | Shanghai Port |

| MOQ | 500 kgs |

EN/DIN Designation: 1.4418

Common Names: Martensitic precipitation-hardening stainless steel.

Similar Standards: Closest equivalent to UNS S17400, AISI 630 (17-4PH), but with specific European composition nuances.

| Element | Min | Max | Typical |

|---|---|---|---|

| Carbon (C) | - | 0.07 | 0.04 |

| Chromium (Cr) | 15.0 | 17.5 | 16.5 |

| Nickel (Ni) | 3.0 | 5.0 | 4.5 |

| Copper (Cu) | 3.0 | 5.0 | 3.5 |

| Niobium (Nb) / Tantalum (Ta) | 0.15 | 0.45 | 0.30 |

| Manganese (Mn) | - | 1.0 | 0.6 |

| Silicon (Si) | - | 1.0 | 0.4 |

| Phosphorus (P) | - | 0.04 | 0.025 |

| Sulfur (S) | - | 0.03 | 0.015 |

| Iron (Fe) | Balance |

High Strength & Hardness: Achieves very high mechanical properties through precipitation hardening heat treatment (H900, H1025, H1150, etc.).

Good Corrosion Resistance: Superior to standard martensitic grades; comparable to Type 304 stainless in many environments. Resistance improves significantly after hardening.

Good Toughness & Ductility: Especially in the solution annealed condition, facilitating machining/formability before final hardening.

Dimensional Stability: Maintains shape and size well during heat treatment.

Machinability: Good in the solution annealed (Condition A) state. Becomes difficult after hardening.

| Heat Treat Condition | Tensile Strength (MPa) | Yield Strength (0.2% Offset) (MPa) | Elongation (% in 50mm) | Hardness (HRC) |

|---|---|---|---|---|

| H900 | 1310 - 1450 | 1170 - 1310 | 8 - 12 | 40 - 48 |

| H1025 | 1100 - 1240 | 1000 - 1100 | 10 - 14 | 35 - 42 |

| H1150 | 1000 - 1100 | 850 - 950 | 12 - 16 | 30 - 37 |

| Solution Annealed (Condition A) | ~1000 | ~800 | ~15 | ~32 HRB |

High-strength shafts, axles, and fasteners (bolts, studs)

Valve stems and components

Pump shafts and impellers

Aircraft and aerospace components (landing gear parts, fittings)

Nuclear reactor components

Oil & gas industry parts (downhole tools, valves)

Gears, spindles, and high-stress mechanical parts

Form: Round Bars (Solid)

Diameter Range: Typically 5mm (0.2") to 250mm (10") or larger (subject to mill capability).

Length: Standard mill lengths (e.g., 3000mm, 6000mm) or cut-to-size.

Peeled/Turned

Ground (Precision)

Hot Rolled & Annealed/Pickled (for larger diameters)

Centerless Ground (for tight tolerances)

Solution Annealing (Condition A): Typically 1040°C (1900°F) ±15°C, air cool or rapid cool. Supplied in this state.

Precipitation Hardening: Required to achieve final high strength. Temperature/time depends on desired properties (e.g., H900: 900°F/482°C for 1 hr, air cool).

Excellent combination of high strength, good corrosion resistance, and moderate toughness.

Can be machined to complex shapes in the annealed state then hardened with minimal distortion.

Good weldability (using matching filler and pre/post-heat treatment).

EN 10088-3 (Stainless steels - Part 3: Technical delivery conditions for semi-finished products, bars, rods, wire, sections and bright products of corrosion resisting steels for general purposes)

Can be supplied to other international standards or customer specifications upon request.

Bundled, crated, or boxed for protection against mechanical damage and corrosion during transit/storage.

|