| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Inverter Control Panel |

|---|---|

| Brand Name: | kiwicrane |

| Model Number: | EFB |

| Certification: | ISO/CE |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | USD500-2000/set |

| Payment Terms: | D/A,D/P,T/T,Western Union |

| Supply Ability: | 3000sets one year |

| Delivery Time: | 5-8working days |

| Packaging Details: | wooden case |

| Product name: | inverter control panel for crane traveling |

| Application: | electric crane traveling |

| Power supply: | 3phase 220V-480V |

| Control voltage: | AC24/36/48/110V/220V |

| Control type: | wireless remote control/pendant control |

| Protection level: | IP55 |

| Company Info. |

| Hefei Kiwi Heavy Machinery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

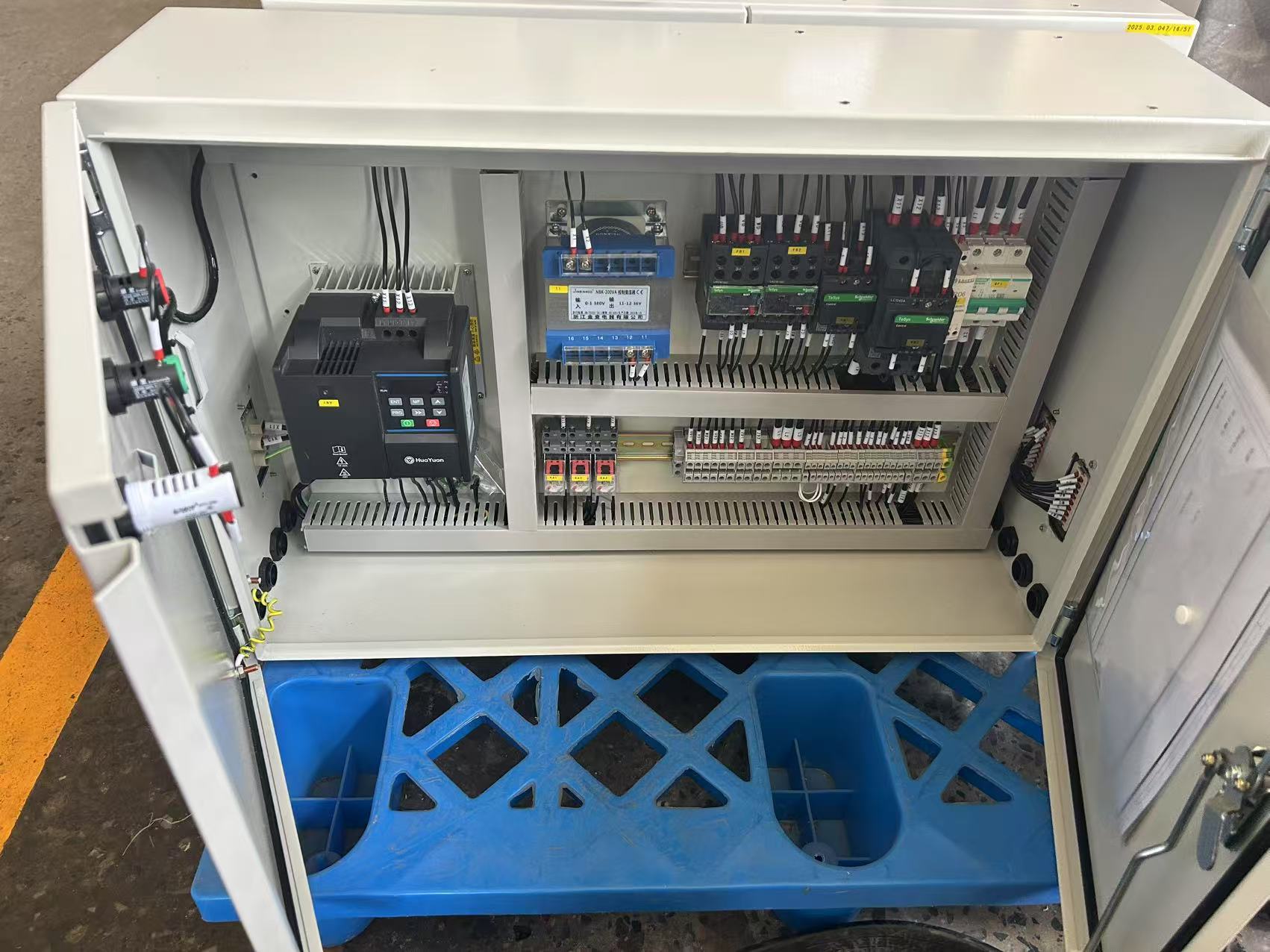

Optimize Your Operations with Inverter Control Panel for Precise Speed Control

1. Highly Compatible Power and Capacity

Motor Power Adaptability: 25-ton cranes (especially the main hoist

mechanism) require significant drive power. The core components of

the inverter cabinet (inverter, brake unit, contactor, circuit

breaker, etc.) must be precisely matched to the motor power (main

hoist motors typically range from 55kW to 75kW or higher, depending

on the hoisting speed and duty cycle).

Heavy-Duty Design: The inverter (especially the hoisting inverter) must be capable of heavy-duty applications (high overload torque, such as 150%-180% rated torque for 60 seconds) to ensure reliability and safety during heavy-load starting, sudden loading, or emergency braking.

Strong Heat Dissipation: High-power components generate significant

heat, making the cabinet's internal heat dissipation system (such

as high-power fans, ductwork, and possibly even rooftop air

conditioning) crucial to ensure temperature rise remains within

acceptable limits during continuous or frequent operation.

2. Extremely High Control Requirements for Hoisting Mechanisms

(Core Focus)

Closed-loop vector control is standard: The main hoisting mechanism

of a 25-ton crane must utilize a closed-loop vector control

inverter with encoder feedback. This is the foundation for the

following key functions:

Zero-Speed Full Torque Hold: When a heavy load (25 tons) is suspended in mid-air, the motor can output sufficient torque (100% rated torque or higher) to prevent the hook from slipping, eliminating the need for prolonged mechanical brake engagement (only for final hold), significantly reducing the risk of brake wear and heat.

Low-Speed High Torque: For precise positioning and inching operations, high torque (>150% rated torque) can be stably output even at extremely low speeds (e.g., <1% rated speed), ensuring smooth and precise movement of heavy loads.

Fast Dynamic Response: Rapid response to speed commands and load changes ensures smooth and safe operation.

|