| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Stainless Steel Pipe |

|---|---|

| Brand Name: | DELTA |

| Model Number: | 347 |

| Certification: | ISO |

| Place of Origin: | China |

| MOQ: | 500 kgs |

| Price: | 5-8 USD/Kg |

| Payment Terms: | L/C,T/T,Western Union |

| Supply Ability: | 3 Ton per week |

| Delivery Time: | 5 - 12 days based on the quantity |

| Packaging Details: | standard packing for export |

| Products: | Stainless Steel Seamless Pipe |

| Grade: | 347 |

| Diameter: | DN10 - DN400 |

| Length: | 6m or custom cutting any length as request |

| Standard: | ASTM EN |

| Service: | Cutting |

| Loading Port: | Shanghai Port |

| Thickness: | 4.0 - 50.0mm |

| Company Info. |

| JIANGSU MITTEL STEEL INDUSTRIAL LIMITED |

| Verified Supplier |

| View Contact Details |

| Product List |

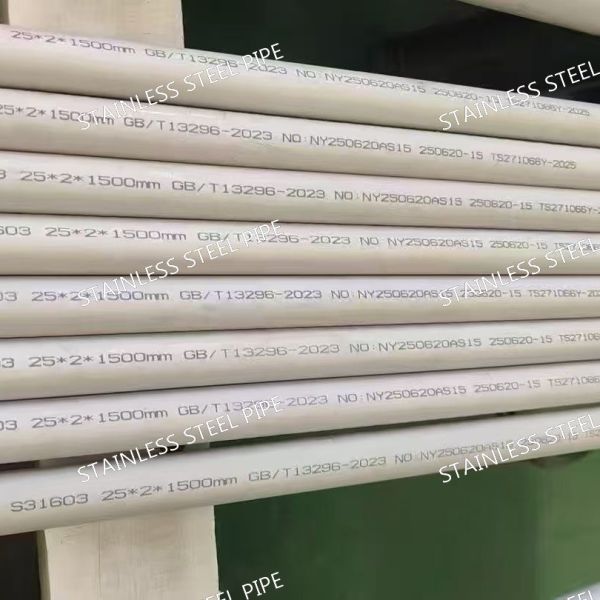

Alloy 347H Stainless Steel Tubing / ASTM A312 Austenitic Stainless Pipes TP347H for Industrial

Products Specification

| Products Name | 347 Stainless Steel Seamless Pipe |

Grade: | 304 304L 309S 310S 314 316L 316Ti 321 329 347H 410 2205 2507 S32760 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

| Element | Content Range (%) | Role in Performance |

|---|---|---|

| Chromium (Cr) | 17.0–19.0 | Forms a protective oxide layer, enhancing resistance to oxidation and corrosion. |

| Nickel (Ni) | 9.0–13.0 | Stabilizes the austenitic structure, improving ductility and toughness. |

| Niobium (Nb) | ≥5×Carbon (C) | Prevents sensitization (carbide formation) during welding or high-temperature exposure. |

| Carbon (C) | 0.04–0.10 | Boosts high-temperature strength and creep resistance. |

| Manganese (Mn) | ≤2.0 | Aids in deoxidation and improves hot workability. |

| Silicon (Si) | ≤1.0 | Enhances oxidation resistance and acts as a deoxidizer. |

| Phosphorus (P) | ≤0.045 | Controlled to minimize brittleness. |

| Sulfur (S) | ≤0.030 | Reduces hot cracking during welding when kept low. |

| Property | Minimum Value | Testing Condition |

|---|---|---|

| Tensile Strength | 515 MPa (75,000 psi) | Room temperature |

| Yield Strength (0.2% offset) | 205 MPa (30,000 psi) | Room temperature |

| Elongation (in 50 mm) | 35–40% | After annealing |

| Hardness (HRB) | 95 (max) | Room temperature |

| Standard | Application Scope |

|---|---|

| ASTM A213/ASME SA213 | Boiler, superheater, and heat exchanger tubes for high-pressure steam systems |

| ASTM A312/ASME SA312 | Seamless and welded pipes for corrosive environments |

| GB/T 14976 | Chinese standard for fluid transport and boiler applications |

| EN 10216-2 | European standard for pressure tubes in high-temperature services. |

| Industry | Applications |

|---|---|

| Power Generation | Boiler tubes, superheaters, reheaters, and high-pressure steam pipelines in coal-fired and gas-fired power plants |

| Petrochemical | Refinery equipment, catalytic crackers, and process piping handling corrosive fluids like hydrogen sulfide |

| Chemical Processing | Reactors, heat exchangers, and pipelines for acids, alkalis, and organic solvents. |

| Aerospace | Exhaust systems and structural components in jet engines and aerospace propulsion systems |

|