| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | PVC Pipe Extrusion Line |

|---|---|

| Brand Name: | LB |

| Model Number: | LB-110 |

| Certification: | CE ISO9001 |

| Place of Origin: | ZHANGJIAGANG, JIANGSU |

| MOQ: | 1 SET |

| Price: | USD EUR |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 15 SETS PER MONTH |

| Delivery Time: | 30 WORKING DAYS |

| Packaging Details: | NORMAL PACKAGE |

| PIPE DIAMETER: | 75-250 |

| EXTRUDER'S POWER: | 55KW |

| COLOUR: | CUSTOMIZED |

| PIPE UMBERS: | SINGLE PIPE |

| RAW MATERIAL: | PVC POWDER & ADDITIVES |

| APPLICATION: | WATER SUPPLY PIPE |

| Voltage: | 380V 50Hz or customized |

| Automatic grade: | Full-automatically |

| Screw design: | Twin screw and barrel |

| After-sales service provided: | Engineers available to service machinery overseas,Field installation,commissioning and training,Online support,Video technical support |

| Warranty: | 18 months |

| Inverter: | ABB |

| Color: | Customizable |

| Raw material: | PVC Powder |

| Motor: | SIEMENS Brand |

| Contactor: | SIEMENS OR SCHNIDER |

| Screw and barrel: | Conical twin screw extruder |

| Screw diameter: | 65/132 |

| Pipe Application: | Water Supply |

| Packages: | Film and boxes |

| Payment: | T/T, L/C, Western Union |

| Delivery time: | 60 days |

| Company Info. |

| Zhangjiagang Langbo Machinery Co. Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

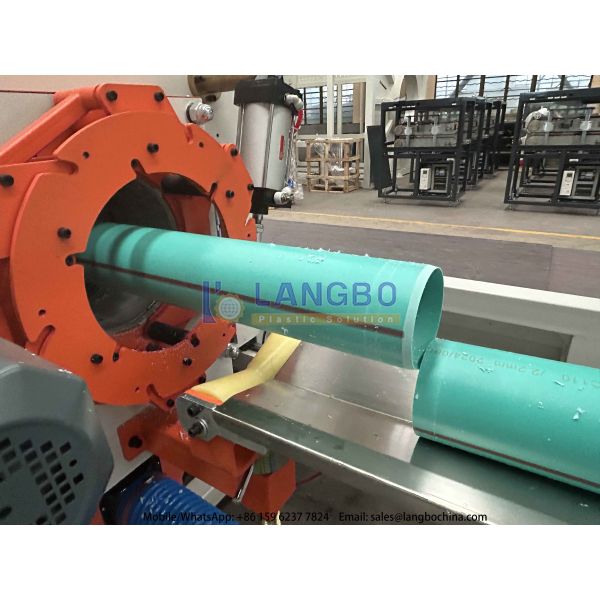

Plastic PVC Gas Water Supply PVC Pipe Extruder Making Machine

Short desciption

PVC series plastic pipe production line is mainly used for producing pipe of water supply and drainage in the field of agriculture and construction cable etc. This machine consists of vacuum calibration tank, haul off unit, cutting unit, stacker etc. The single screw extruder and haul off unit apply famous A/C frequency conversion speed regulation device, both vacum pump and driving motor apply famous brand. The haul-off unit includes two-claw type, three-claw type, four-claw type, six-claw type, eight-claw type, ten-claw type, twelve-claw type etc. Dust fre cutting machine, saw blade cutting machine or planetary cutting machine can be applied, the property of machine group is reliable. The production efficiency is high with special device, it can produce inner wall spiral pipe, inner wall hollow pipe, and core layer foam pipe. It can also produce PP/PE/ABS/PPR/PEX/Silicon core pipe etc. The planetary cutting machine is controlled automatically with computer, it has such advantages of simple operation, reliable performance etc. It has reached international advanced level.

Tech Features & Advantages

Plumbing and Water Supply Systems (potable water distribution,

drainage).

Sewer and Wastewater Systems (municipal sewer networks, underground

drainage).

Electrical Conduits (protecting cables and wiring in construction).

Agricultural Irrigation (water transport for crop fields and

greenhouses).

Industrial Piping (chemical transport, ventilation, and compressed

air systems).

Producting process

Raw material +master batches → mixing → vacuum feeder→ material dryer → single screw extruder ( small CO-extruder ) → mould → vacuum calibration tank → spray cooling tank ( water tank) → haul-off unit → cutting machine→ stacker

Specifications:

| MODEL | PIPE DIAMETER (MM) | EXTRUDER MODEL | MOTOR POWER (KW) |

| LB-32F | 16-32 (FOUR PIPE) | SJSZ65/132 | 37 AC |

| LB-32E | 16-32 (DOUBLE PIPE) | SJSZ51/105 | 22 AC |

| LB-32W | 16-32 (DOUBLE PIPE) | SJSZ65/132 | 37 AC |

| LB-40E | 16-40 (DOUBLE PIPE) | SJSZ51/105 | 22 AC |

| LB-40W | 16-40 (DOUBLE PIPE) | SJSZ65/132 | 37 AC |

| LB-50E | 16-50 (DOUBLE PIPE) | SJSZ51/105 | 22 AC |

| LB-50W | 16-50 (DOUBLE PIPE) | SJSZ65/132 | 37 AC |

| LB-63W | 16-63 (DOUBLE PIPE) | SJSZ65/132 | 37 AC |

Product detail

1. Raw Material Mixing & Feeding

PVC resin, stabilizers, plasticizers, and other additives are precisely weighed and mixed in an automatic mixer.

- The blended material is fed into the hopper of the extruder.

2. Extrusion & Pipe Forming

- The twin-screw extruder heats and melts the PVC mixture, pushing it through a die head to form a continuous pipe shape.

- The pipe diameter and wall thickness are controlled by the extrusion die and sizing sleeve.

3. Vacuum Sizing & Cooling

- The newly formed pipe passes through a vacuum sizing tank to ensure precise dimensions.

- It then enters a cooling water tank to solidify the structure and maintain shape stability.

4. Hauling & Cutting

- A haul-off machine pulls the pipe at a controlled speed to maintain consistency. - An automatic cutting machine cuts the pipe into desired lengths (e.g., 4m, 6m). 5. Stacking & Packaging

- The finished pipes are automatically stacked and packed for storage or shipment.

|