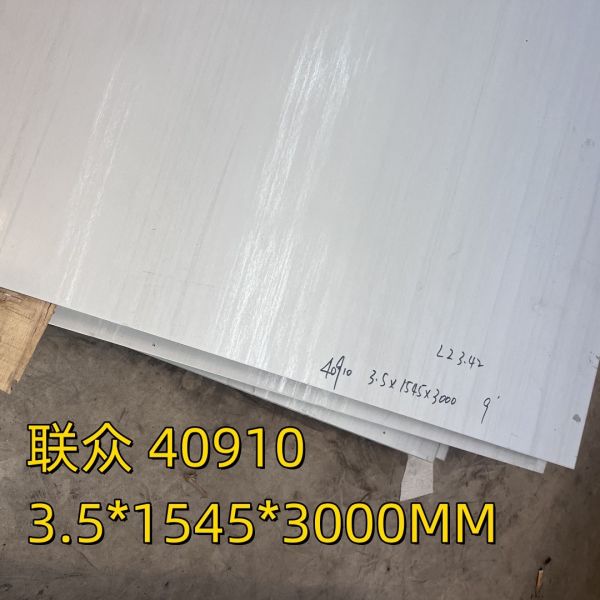

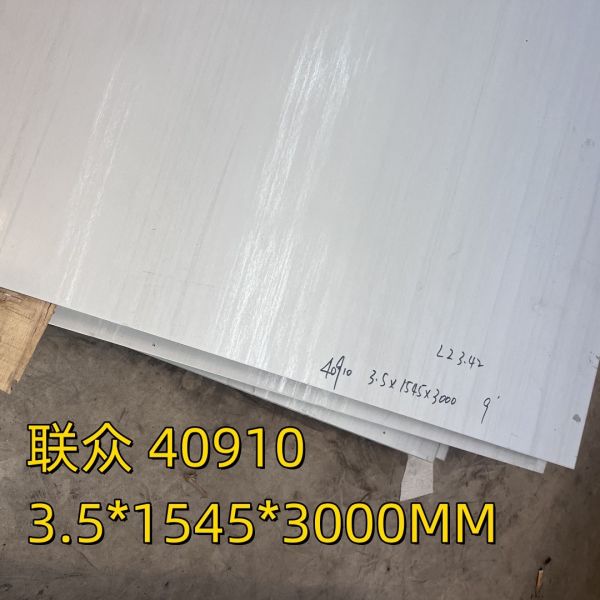

SUH409L UNS S40910 Stainless Steel Plate 1D Finished 3.5mm Hot

Rolled 409L Plate

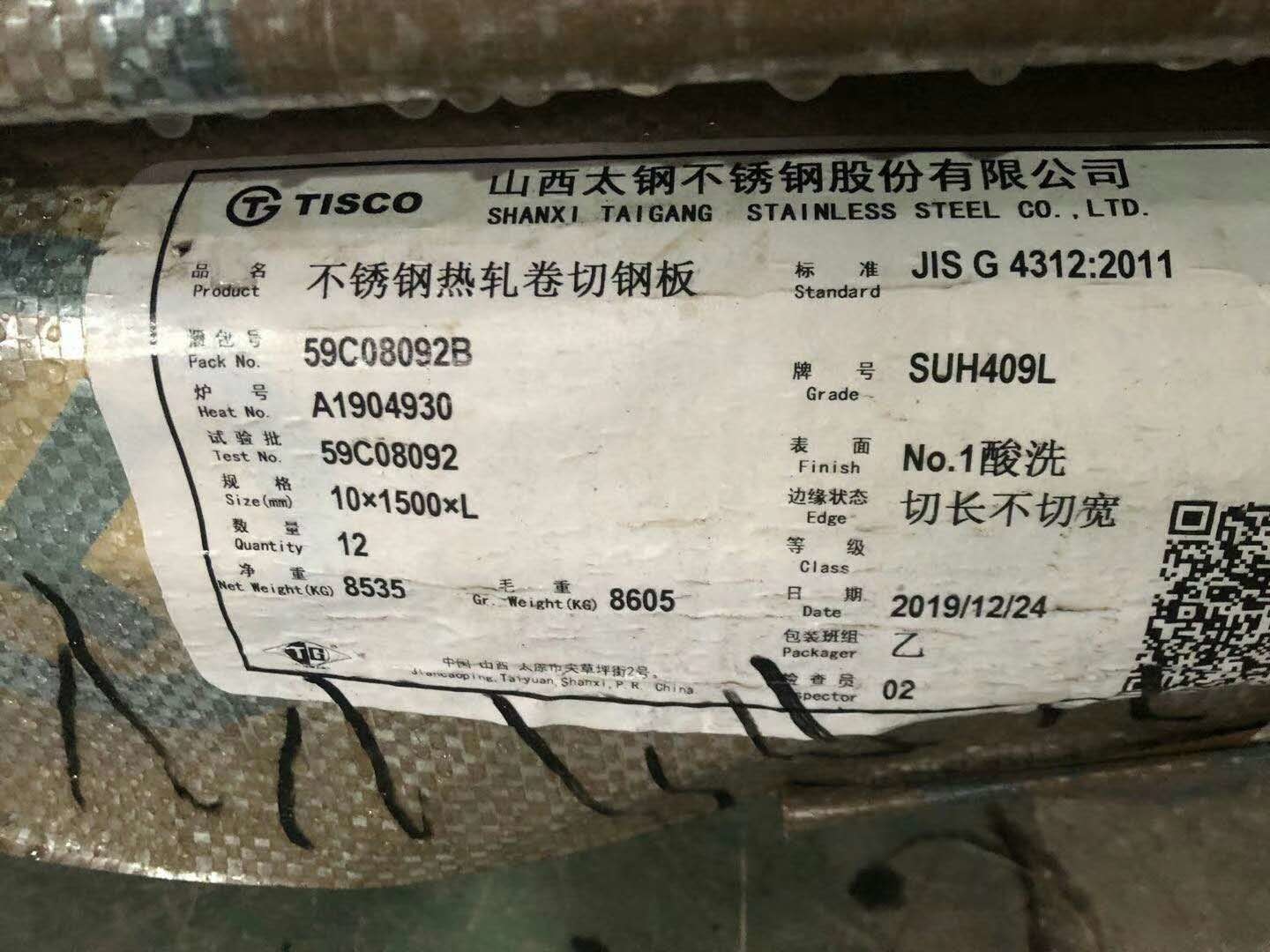

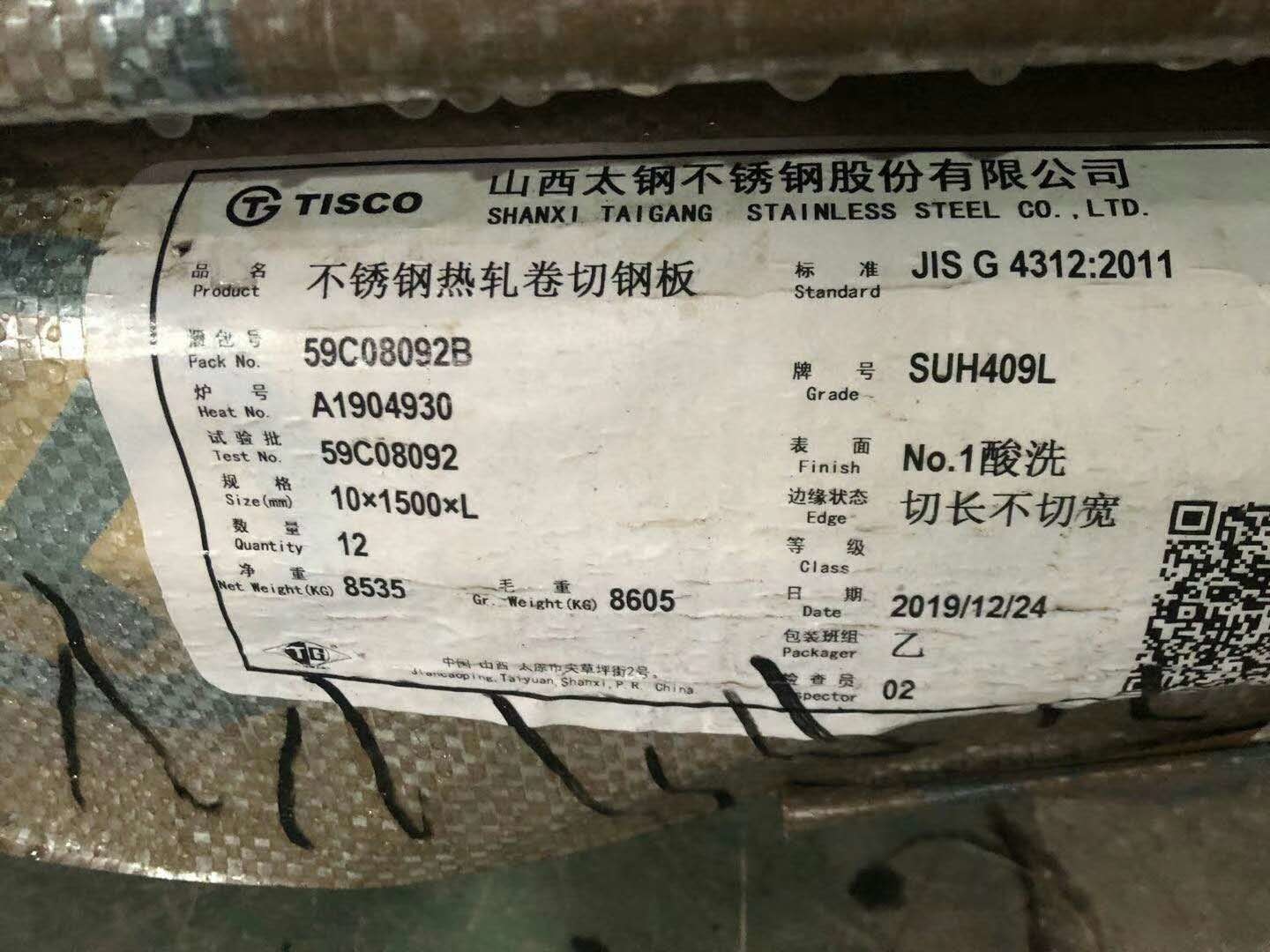

SPECIFICATION

| Specifications | ASTM A240 / ASME SA240 |

|---|

| Dimensions | ASTM, ASME and API |

|---|

| Standard | JIS, AISI, ASTM, GB, DIN, EN, etc. |

|---|

| Surface | 2B, 2D, BA, NO.4, NO.8, 8K, Mirror,Checkered, Embossed, Hair Line,

Sand Blast, Brush, Etching |

|---|

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm,etc. |

|---|

| Finish | Black,Bright Polished,Rough Turned,No.4 Finish,Matt Finish,BA

Finish |

|---|

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

|---|

CHEMICAL COMPOSITION OF STAINLESS STEEL 409L PLATES

| Grade | C | Mn | Si | S | P | Cr | Ni | Ti |

| SS 409L | 0.03 max | 1.00 max | 1.00 max | 0.030 max | 0.040 max | 10.50-11.70 | 1.5 max | - |

MECHANICAL PROPERTIES OF ASTM A240 STAINLESS STEEL 409L SHEETS

| Element | Density | Tensile Strength | Yield Strength (0.2%Offset) | Elongation | Hardness |

| SS 409L | 7.8 g/cm3 | MPa – 380 | MPa – 170 | 20 % | Rockwell B (HR B)- 88 / Brinell (HB)- 0.5t |

Stainless steel plate surface description

| Finish Designation | Method and degree of finish |

| No.1 | After hot rolling, heat treatment, pickling or other equivalent

treatment is applied. |

| No.2D | Annealing and pickling are performed after cold rolling; material

is soft with surface of silver-white luster; used for general

applications and deep drawing. |

| No.2B | After 2D finish, skin pass rolling is performed to obtain a more

suitable luster; the surface becomes very exquisite; used for

general applications. |

| No.3 | Intermediate 100-120 grit finish; used for applications in which

surface polishing is performed after shaping. |

| No.4 | General 150-180 grit finish; used for restaurants and kitchen

equipment and tools. |

| #240 | 240 grit finish; used when a finer finish than No. 4 is required;

typically for restaurants and kitchen equipment and tools. |

| #320 | 320 grit finish polished product. |

| HL | This finish is performed by continuous linear polishing using an

abrasive of appropriate grain size; mainly used for architectural

applications. |

| BA | Achieved by performing bright annealing after cold rolling and then

skin pass rolling to obtain even greater reflectance; provides

excellent corrosion resistance; used for household appliances,

kitchen equipment, and automobiles. |

| 8K | Through multiple grinding, it achieves very high brightness and

smoothness, like a mirror. |

Q1. What are your company's main products ?

A1: Our main products are stainless steel plate/sheet, coil,

round/square pipe, bar, channel, etc.

Q2. Where is your factory ?

A2: Our company's processing center is located in Jiangsu, Wuxi,

China.

Which is well equipped with kinds of machines, such as laser

cutting machine,mirror polishing machine and so on.

We can provide a wide range of personalized services according to

the customers' needs.

Q3:How to confirm the Product Quality before placing orders?

A3:You can get free samples for some products,you only need to pay

the shipping cost or arrange a courier to us and take the samples.

The third-party will be accepted.

Q4. What are the advantages of your company ?

A4: We have many professionals, technical personnel, more

competitive prices and best after-dales service than other

stainless steel companies.

Q5. How many coutries you already exported ?

A5: Exported to more than 50 countries mainly from America, Russia,

UK, Kuwait, Egypt,Turkey, Jordan, India, etc.

Q6:What is your delivery time?

A6: For stocks, we could transport the goods to loading port within

7 days after we received your deposit

For production period, it usually takes about 15 days-30 days after

receiving the deposit.

Q7. Can you provide sample ?

A7: Small samples in store and can provide the samples for free.

Customized samples will take about 5-7days.