| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Prepainted Galvanized Steel |

|---|---|

| Brand Name: | HuiYi-PPGI |

| Model Number: | G550,CGCC |

| Certification: | ASTM, JIS, GB |

| Place of Origin: | China |

| MOQ: | 22MT |

| Price: | Negotiation |

| Payment Terms: | T/T, L/C, D/P |

| Supply Ability: | 5000MT/Month |

| Delivery Time: | 15-30 Days |

| Packaging Details: | Exporting Packing with 3layers including the waterproof plastic film,Waterproof paper - plastic film-metal wrap. |

| Product Name: | Prepainted Galvanized Steel Coil |

| Type: | Steel Coil |

| Grade: | CGCC |

| Width: | 600-1500mm |

| Surface: | Matte , galvanized |

| Tolerance: | ±10% |

| Front Paint Coating: | 15-35um |

| Surface Protection: | PE, PVDF, SMP, HDP |

| Application: | Construction, Appliances, Transportation, Furniture |

| Surface Treatment: | Degreasing, Phosphating, Chromate Treatment |

| Company Info. |

| Shanghai Huiyi International Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

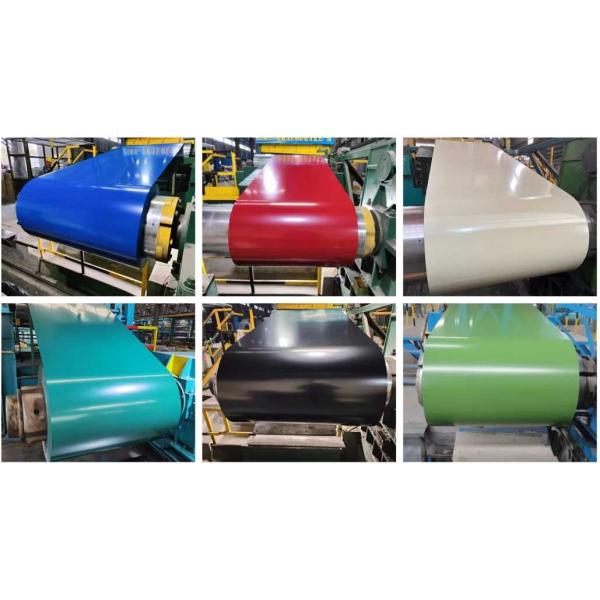

PPGI is pre-painted galvanized steel, also known as pre-coated steel, color coated steel etc.

Using Hot Dip Galvanized Steel Coil as the substrate, PPGI is made by first going through surface pretreatment, then the coating of one or more layers of liquid coating by roll coating, and finally baking and cooling. The coatings used including polyester, silicon modified polyester, high-durability, corrosion-resistance and formability.

We could also provide the product life length lasts for decades as customers required.

| Attribute | Details |

|---|---|

| Product Name | PPGI Steel Coil |

| Grade | CGCC |

| Yield Strength | 280-560N/mm² |

| Material | Galvanized Steel Coil |

| Material Standard | JISG3302 |

| Width | 600-1250mm |

| Zinc Coating | AZ50, AZ80, AZ100, AZ120 |

1. Construction Industry

- Used for roofing, wall panels, ceilings, and other building

materials, providing excellent waterproofing, corrosion resistance,

and decorative effects.

- Suitable for large-scale buildings such as industrial plants,

warehouses, and gymnasiums.

2. Home Appliance Manufacturing

- Used for the exteriors of refrigerators, washing machines, air

conditioners, and other household appliances, combining aesthetics

with durability.

- Offers a variety of colors and surface treatments to meet

different design requirements.

3. Transportation

- Used for interior and exterior decorations and structural

components of vehicles such as cars, trains, and ships.

- Lightweight design helps reduce vehicle weight and improve fuel

efficiency.

4. Furniture Manufacturing

- Used for office furniture, kitchen equipment, storage cabinets,

etc., providing durable and aesthetically pleasing surfaces.

- Easy to clean and maintain, making it suitable for high-frequency

use environments.

5. Electronics and Electrical Appliances

- Used for electronic device casings, distribution boxes, control

cabinets, etc., offering excellent electromagnetic shielding and

protective performance.

- Suitable for demanding industrial environments.

6. Advertising and Signage

- Used for billboards, signage, display racks, etc., providing

vibrant colors and durability.

- Ideal for outdoor use with strong weather resistance.

Packing:Exporting Packing with 3layers including the waterproof plastic film, Waterproof paper - plastic film-metal wrap.

1. What is PPGI?

Answer: PPGI (Pre-Painted Galvanized Iron) is a pre-painted

galvanized steel sheet coated with a polypropylene layer. It

combines the corrosion resistance of galvanized steel with the

decorative and protective properties of the polypropylene coating.

2. What are the main uses of PPGI?

Answer: PPGI is widely used in construction (e.g., roofs, wall panels), home appliances (e.g., refrigerator and washing machine panels), furniture, automotive parts, and various industrial applications requiring corrosion resistance and an attractive appearance.

3. What is the difference between PPGI and ordinary galvanized

steel?**

Answer: PPGI adds a polypropylene coating to ordinary galvanized

steel, providing better corrosion resistance, decorative appeal,

and scratch resistance. Ordinary galvanized steel, on the other

hand, is primarily used for basic rust prevention and has a simpler

surface.

4. How is the corrosion resistance of PPGI?

Answer: PPGI offers superior corrosion resistance compared to ordinary galvanized steel because the polypropylene coating provides an additional protective layer, effectively shielding the base material from moisture, chemicals, and UV exposure.

5. Can the surface of PPGI be customized in terms of color and

texture?

Answer: Yes, the surface of PPGI can be customized in various

colors, textures, and finishes to meet the aesthetic and functional

requirements of different applications.

6. What should be considered during the installation and

maintenance of PPGI?

Answer: During installation, avoid scratching the coated surface,

and it is recommended to use specialized tools and fittings. For

maintenance, regularly clean the surface and avoid using corrosive

cleaning agents to extend its service life.

|