| Parameters | Units | UnitsBSM65S-5L Seires | BSM70D-5L Seires |

| Screw diameter | mm | 65 | 70 |

| (50HZ)Screw L/Dratio | - | 24 | 24 |

| (50HZ)ScrewRPM(50HZ) | r/min | 10-70 | 10-70 |

| Extrusion capacity per hour(PE) | kg/h | 60 | 70 |

| Number of heaters | - | 3 | 3 |

| Number of heaters | mm | 420 | 420 |

| Platen size | mm | 320*410 | 320*410 |

| Clamping stoke | mm | 150-500 | 150-500 |

| Clamping force | KN | 68 | 68 |

| Dry cycle time | S | 5 | 7 |

| Cooling water pressure | Mpa | 0.2-0.3 | 0.2-0.3 |

| Cooling water consumption | L/min | 50 | 50 |

| Air pressure | Mpa | 0.8 | 0.8 |

| Compressed air consumption | m³/min | 0.4 | 0.4 |

Wide Mouth Jar Machine Extrusion Blow Molding Machine: A

Comprehensive Introduction

In the realm of plastic manufacturing, the extrusion blow molding

machine stands as a crucial piece of equipment, especially when it

comes to producing wide mouth jars. This technology has

revolutionized the production process, offering efficiency,

versatility, and high - quality output.

Working Principle

The extrusion blow molding process for wide mouth jars begins with

the plastic material, typically polyethylene (PE), high - density

polyethylene (HDPE), or polypropylene (PP). These raw materials are

fed into the hopper of the extrusion blow molding machine. Once

inside, they are heated in the barrel by a combination of

electrical heaters and the mechanical energy generated by the

rotating screw. As the plastic melts, the screw pushes it forward

towards the die head.

The die head is a critical component as it shapes the molten

plastic into a parison, which is a hollow tube - like structure.

The parison is then carefully dropped into a pre - designed mold

cavity that is shaped like the desired wide mouth jar. Once the

parison is in place, the mold closes around it. Immediately after,

compressed air is injected into the parison through a blow pin. The

pressure of the air causes the parison to expand and conform

precisely to the inner surface of the mold cavity. This is how the

wide mouth jar takes its final shape.

After the jar has been blown to the correct shape, it is left to

cool inside the mold. Cooling is a crucial step as it solidifies

the plastic, ensuring that the jar retains its shape. Once cooled,

the mold opens, and the newly formed wide mouth jar is ejected. In

some advanced machines, there are automated systems for removing

any excess plastic or flash that may have formed during the

process.

Applications

Packaging Industry

Wide mouth jars produced by extrusion blow molding machines are

extensively used in the packaging industry. They are ideal for

packaging food products such as jams, jellies, pickles, and honey.

The wide mouth design allows for easy access to the contents,

making it convenient for consumers. In the cosmetics and personal

care sector, these jars are used to package creams, lotions, and

body butters. Their air - tight seals help in preserving the

quality and shelf - life of the products.

Industrial Applications

Industrial chemicals, lubricants, and adhesives often require

containers that can withstand harsh substances. Wide mouth jars

made by extrusion blow molding machines are suitable for such

applications as they can be made from materials with high chemical

resistance. They are also used for storing and transporting various

industrial products due to their durability and ability to be

stacked easily.

Consumer Goods

In the consumer goods market, wide mouth jars are used for storing

a variety of items at home. From storing dry goods like pulses and

cereals to organizing small household items, these jars provide a

practical and aesthetically pleasing storage solution. Their

transparency (in the case of some plastics) allows for easy

identification of the contents.

Advantages

Cost - Effective Production

Extrusion blow molding machines offer cost - effective production

for wide mouth jars. The process is relatively simple compared to

some other plastic - forming methods, which reduces the need for

complex tooling and machinery. Additionally, the ability to produce

large quantities of jars in a short time, along with the efficient

use of raw materials, helps in keeping the production costs down.

Design Flexibility

Manufacturers have a high degree of design flexibility when using

extrusion blow molding machines for wide mouth jars. The shape of

the mold can be customized to create jars with different sizes,

shapes, and features. For example, jars can be designed with

threaded lids, handles, or embossed logos. This flexibility allows

companies to create unique packaging that stands out in the market.

High - Quality Output

The extrusion blow molding process results in high - quality wide

mouth jars. The uniform distribution of plastic during the blowing

process ensures that the jars have consistent wall thickness, which

is essential for their strength and durability. The smooth inner

and outer surfaces of the jars make them suitable for both storing

products and for printing labels or applying other decorative

elements.

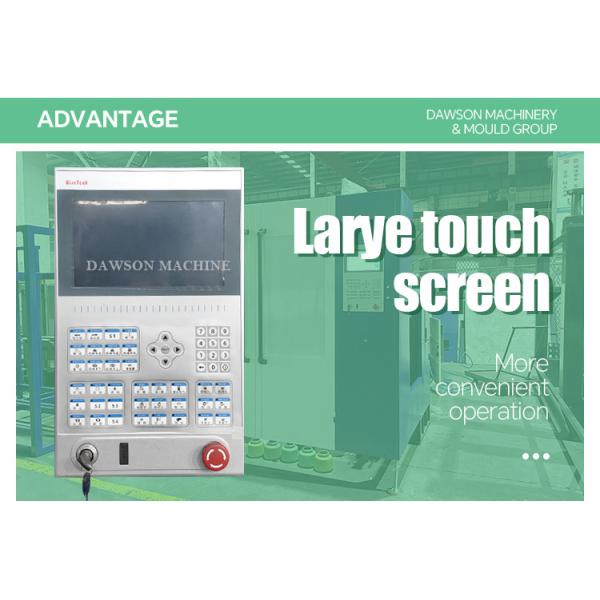

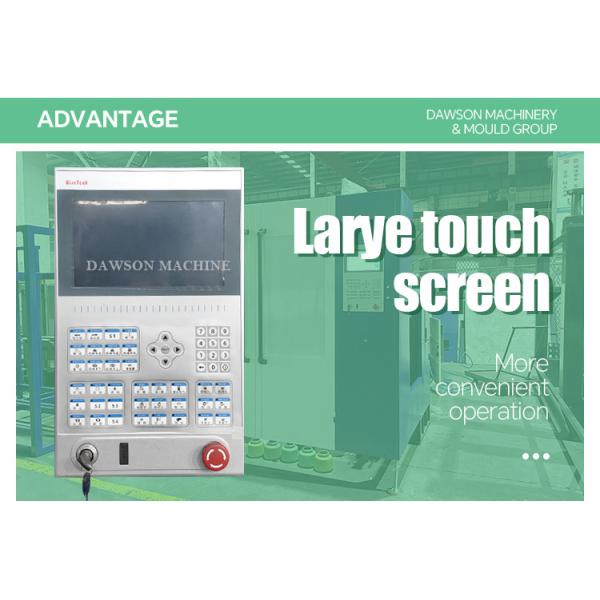

Technological Advancements

Modern extrusion blow molding machines for wide mouth jars are

equipped with advanced features. Many machines now come with

computer - controlled systems that precisely monitor and adjust

various parameters during the production process. These parameters

include temperature, pressure, and the speed of the screw. This

level of control ensures that each jar produced meets the highest

quality standards.

Some machines also have energy - saving features. For instance,

they use advanced heating systems that are more energy - efficient,

reducing the overall power consumption of the machine.

Additionally, there are improvements in the cooling systems, which

not only speed up the production cycle but also contribute to

energy savings.

In conclusion, the Wide Mouth Jar Machine Extrusion Blow Molding

Machine is an essential tool in the plastic manufacturing industry.

Its working principle, wide range of applications, numerous

advantages, and continuous technological advancements make it a

reliable and efficient choice for producing high - quality wide

mouth jars. As technology continues to evolve, we can expect even

more improvements in the performance and capabilities of these

machines.

DAWSON MACHINE & MOULD GROUP

located in Zhangjiagang city, have more than 18 years' experience

in the field of plastic machinery,

injection molding machine, blow molding machine, PET blow molding

machine, injection blow molding machine, during the past 18 years,

we always force our energy into new areas of plastic machinery,

plastic packaging machinery, to update the technology, to learn

advanced experience, to confirm new theory and new design, we are

forming a unique competitive advantage of our owns.

The machines from our company carry good quality and effective

after-sales service, upon the market,customers from more than 45 countries, we provide complete solution

for your plastic industry business, as well as all sorts of technical support & after-sale

services!

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai.

For overseas customers, you can fly to Shanghai Pudong

International Airport. We can pick you up in the Airport. (or

Hongqiao International Airport. ) We also provide visit online by

video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo

if possible. We can recommend our machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us

for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before

loading,after shipment we provide 24 HRS online support, video

technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual

production cycle will vary according to the degree of

customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and

stable performance. We design the machines according to customers

products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for

guiding the installation and commission the machine, also train the

customer's employees.

Q: What's DAWSON's advantage?

DAWSON provide customers with turnkey projects. Including plant

design, plastic machine and mold installation, debugging, also we

can source the auxiliary equipment for customers. We can ship the

full set of machines after testing in our factory. It will save a

lot of cost and time.

DAWSON will be your reliable friend in China, and we will always do

our best to give you max support!