| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | CNC Turning Parts |

|---|---|

| Brand Name: | PFT |

| Model Number: | OEM/ODM |

| Certification: | ISO13485, IS09001, AS9100, IATF16949 |

| Place of Origin: | China |

| MOQ: | 1pcs |

| Price: | 0.49 |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 300,000pcs |

| Delivery Time: | 7-15 day |

| Packaging Details: | custom |

| Shape: | Round |

| Ship Method: | DHL/UPS/Fedex/TNT/EMS |

| Shipping Method: | Express, Air, Sea, Etc. |

| Identification: | ISO SGS Rohs |

| Package: | Bubble and Carton or Customization |

| Machining Service: | OEM ODM Customised |

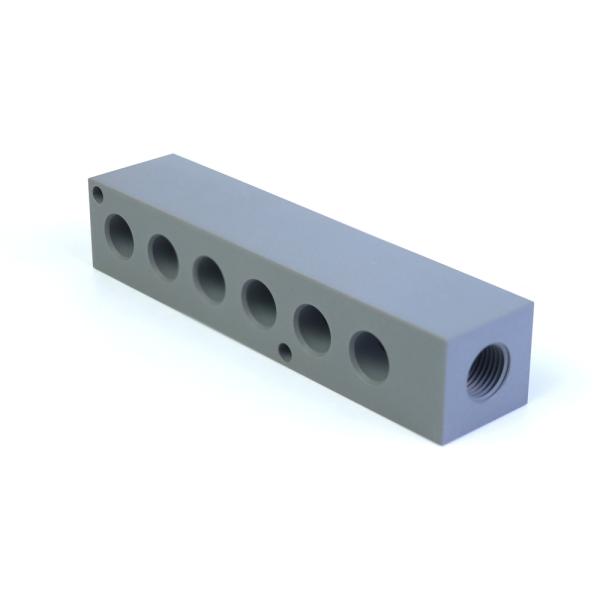

| Product: | CNC Turning Parts |

| Type Available: | Milling, Turning, Drilling Etc |

| Trademark: | BY |

| Categories: | CNC Turning Parts |

| Equipment: | CNC Machining Centres |

| Technology: | 10 Years Experience |

| Factory Visit: | Welcome Anytime |

| Oem: | Available,Offered,Accept |

| Company Info. |

| Shenzhen Perfect Precision Product Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Hey there! If you’ve ever thought that manufacturing medical parts is all about cold, hard metal and precise machines, you’re in for a surprise. Today, we’re diving into a topic that’s way more fascinating than it sounds: painting medical turning parts.

Honestly, that’s what most people think. But in the world of medical devices, a coat of paint isn’t about making something pretty. It’s a critical, life-saving step in the manufacturing process. Let’s break down why.

Think about the environment these parts live in. We're talking about surgical tools, components inside diagnostic machines, or parts of a hospital bed. They face a daily assault of:

A bare metal part, no matter how well-machined, would corrode, rust, and degrade over time. The right specialized coating acts as an invisible shield, protecting the integrity of the part and ensuring it performs reliably, surgery after surgery, year after year.

Friction is the enemy in many medical devices. Imagine a component inside an insulin pump or a surgical robot that needs to move smoothly and precisely. Any unwanted friction can lead to failure.

Certain high-performance coatings are engineered to be incredibly slick. By applying them to turned parts, we drastically reduce friction, which means less wear on the components, smoother operation, and ultimately, a more reliable and accurate medical device.

This is the big one. Everything comes back to patient safety. A chipped or corroded part can shed microscopic particles. A part with poor friction can jam at a critical moment. The right coating prevents this.

Furthermore, many coatings are designed to be biocompatible. This is a fancy word meaning the coating is specifically formulated to be safe for contact with the human body without causing any adverse reactions. It’s non-toxic, inert, and incredibly safe.

You can’t just use any paint from the hardware store. This stuff is high-tech. Medical-grade coatings are:

The next time you see a sleek, colored medical instrument or a component from a complex machine, remember—that color isn’t just for branding. It’s the final, crucial step in a journey of precision engineering. It’s a testament to the incredible attention to detail that goes into every aspect of healthcare, right down to a single, tiny, turned part.

It’s not just paint. It’s peace of mind, engineered onto a surface.

1. Are you a manufacturer or a trading company?

|