| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | High Speed Circular Saw Machine |

|---|---|

| Brand Name: | JSSCD |

| Model Number: | JSSCD-160NC/X |

| Certification: | HB24Q00435R0S HB24E0025 HB24S00242R0S8R0S |

| Place of Origin: | China |

| MOQ: | 1 |

| Delivery Time: | 7-60 work days |

| Packaging Details: | depending on the machine model |

| Payment Terms: | FOB |

| Supply Ability: | 500 Sets Per Year |

| Name: | JSSCD- 160NC/X CNC High Speed Circular Saw Machine |

| Condition: | New |

| Use: | Material cutting |

| Cuttable material: | Carbon steel,Stainless steel,Alloy steel,Aluminum,Aluminum alloy,Copper,Copper alloy,Titanium alloy,PA |

| Saw type: | Diagonal cut |

| Cutting precision: | ±0.05mm |

| Feeding precision ±0.05mm: | ±0.1mm |

| Special requirement: | Customized services are available |

| Safety protection devices: | Emergency braking,Anti-splash shield |

| Color: | Red,Black |

| Dimension: | 2240x2320x2040 |

| Application: | Automobile manufacturing,Aerospace,Rail transit,Mechanical equipment,Hardware tools,Ship building,Building material,Pipeline engineering,Mold manufacturing,Electronics manufacturing |

| Mechanical control: | Intelligent control,Automation |

| FAT: | Sample trial cutting verification |

| Hydraulic oil: | Reusable |

| Cutting debris removal device: | Chain plate chip conveyer |

| Company Info. |

| Jiangsu Sakoste Intelligent Machinery Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

JSSCD-160NC/X CNC High Speed Circular Saw Machine for Metal Cutting

Descriptions

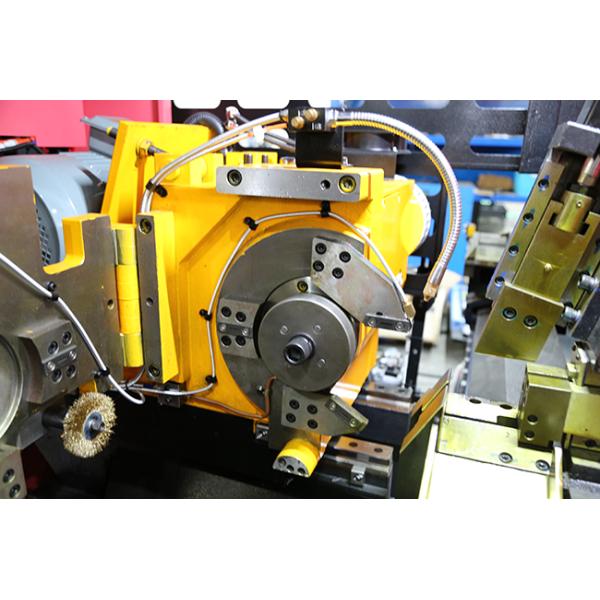

JSSCD-160NC/X CNC High Speed Circular Saw Machine (Angled-Push) - This CNC high-speed circular saw is specially crafted for metal profile cutting tasks, with a particular strength in angled cutting operations. Boasting a one-of-a-kind 15° top-to-bottom cutting approach, along with features like high-speed cutting, automated control, precise operation, and eco-friendly performance, it plays a vital role in the metal processing sector and has become an essential piece of equipment in numerous production facilities.

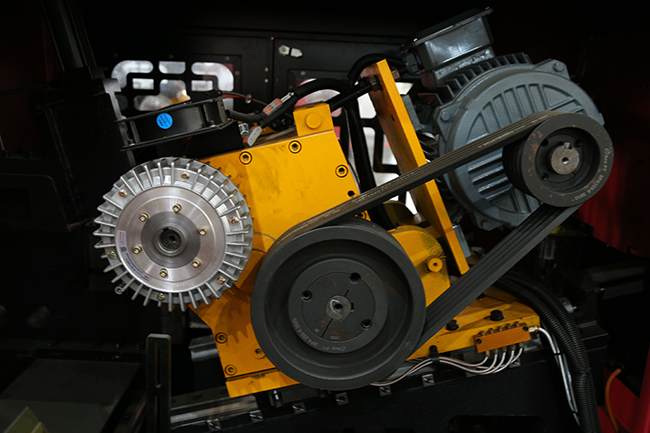

This machine is applicable to the processing of various profiles including round tubes, angle steels, and square tubes. It eliminates the need for frequent fixture changes, greatly boosting processing flexibility and adaptability. It can effortlessly cater to the cutting demands of metal materials in different sizes and forms. The 15° top-to-bottom cutting method works to effectively spread out stress during cutting, lessening the impact on the workpiece and resulting in smoother, flatter cut edges. It is especially well-suited for processing situations where cut edge quality is of high importance. The machine is fitted with an advanced transmission and clamping system, which utilizes high-strength materials and accurate structural design to securely hold the workpiece. Even when cutting at high speeds, it prevents displacement, ensuring the cutting process is steady and dependable. The intelligent control module acts as the "core" of the machine, capable of precisely regulating cutting speed, angle, and other processes to achieve efficient and accurate cutting, guaranteeing each cut meets the desired standards.

Specifications:

| Model | Unit | JSSCD-160NC/X |

| Mainframe dimensions | mm | 2240*2320*2040 |

| Bar & round pipe | mm | 40-160 |

| Angle bar & square bar | mm | 40-130 |

| Saw blade size | mm | φ480*2.7*φ50 |

| Pin holes and hole diameters | mm | 4*φ16*80 φ50 |

| Spindle motor power | KW | 18.5/15 |

| Spindle speed | rpm | 20-110 |

| Feeding servo motor power | KW | 2.7 |

| Feed servo motor power | KW | 2.3 |

| Material removal length at the front end | mm | 10-99 |

| Single feeding length(repeatable) | mm | 10-800 |

| Hydraulic drive motor power | KW | 3.75(4p) |

| Rated pressure of the hydraulic system | mpa | 5.5 |

| Hydraulic oil capacity | L | 110 |

| Cut off feed mode | AC servo motor & ball screw / 15° cutting-in | |

| Main clamping method | Hydraulic type / one set each for horizontal and 15° | |

| Saw blade debris removal device | Passive/active circular wire brush (optional) | |

| Gear backlash compensation device | Hollow external rotating magnetic powder brake | |

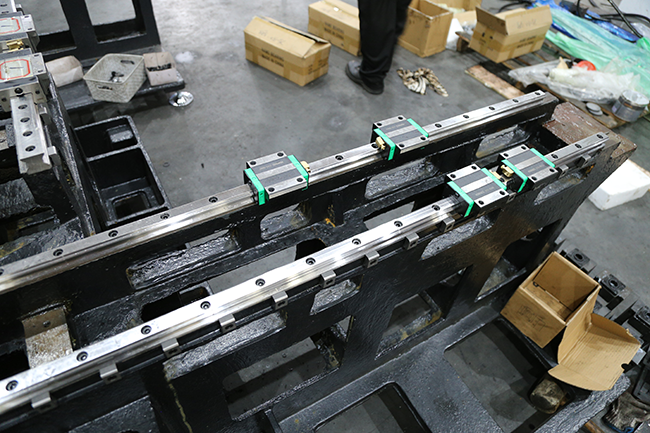

| Feeding drive mode | AC servo motor & ball screw | |

| Feeding clamp method | Hydraulic type/Horizontal clamping | |

| Residual material length at the rear end | mm | 90&a(a represents the length less than one cut-off workpiece) |

| Self-lubrication oil system | Timed and quantitative forced oil supply | |

| Micro-lubrication system for cutting | Quasi-dry intermittent oil supply | |

| Material separating device | Pneumatic reciprocating | |

| Long material receiving device | Optional | |

| Blade swing anti-vibration device | Tungsten carbide parallel block |

Furthermore, it comes with a high-precision CNC control system that supports human-machine interface programming. Operators can simply make basic settings on the user-friendly interface to pre-set cutting parameters and save multiple processing programs, enabling fully automated production. This significantly cuts down on manual involvement and reduces errors caused by human actions. Additionally, an optional automatic feeding system is available, which allows for continuous batch cutting, enabling the machine to keep producing without stoppages, further raising production efficiency and satisfying the large-scale production needs of enterprises.

It can handle both large-volume production and high-precision processing requirements with ease, effectively aiding enterprises in enhancing production efficiency and processing quality, while offering a stable and reliable cutting solution for metal processing lines. By leveraging intelligent control and high-speed cutting technology, this machine can notably improve material utilization, reduce material waste, enhance production efficiency, shorten production cycles, and lower labor costs. This makes it a perfect choice for metal processing enterprises looking to boost their competitiveness and a superior option for modern metal processing workshops, providing a strong driving force for the sustainable development of enterprises.

FAQ

Q1: Are you a manufacturer or a trading company?

A:We are a professional manufacturer of saw blade grinders. We have a 30,000 square meter factory and a team of dedicated technicians specializing in design, manufacturing, and sales.

Q2. Where is your factory located?

A:Our factory is located in Nantong City, Jiangsu Province, China.

It will takes about 1.5 hours from Shanghai Hongqiao station to our city

Q3: What is your factory acceptance test method?

A: You can send us sample material to be cut, and we will perform a test cut using our machine. After the test is complete, we will provide you with detailed cutting data. (We will also send you a video of the machine cutting operation for your confirmation.)

Q4:What is your method of transaction?

A:We adopt the FOB(Free ON Board) transaction.

Q5: How about your delivery time?

A: Generally, it will take 7-60 work days after receiving your order.

The specific delivery time depends on the items and the quantity of your order.

Q6:How about the payment term

A:T/T 30% deposit, 70% of balance paid before shipment. (For other payment methods please contact our sales team)

Q7:Does the band saw blade have any international certifications?

A:Yes,we have obtained CE,ISO international certification.

|