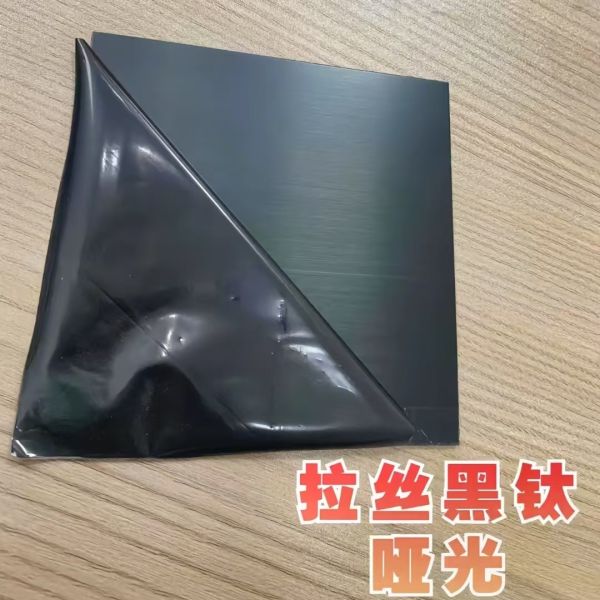

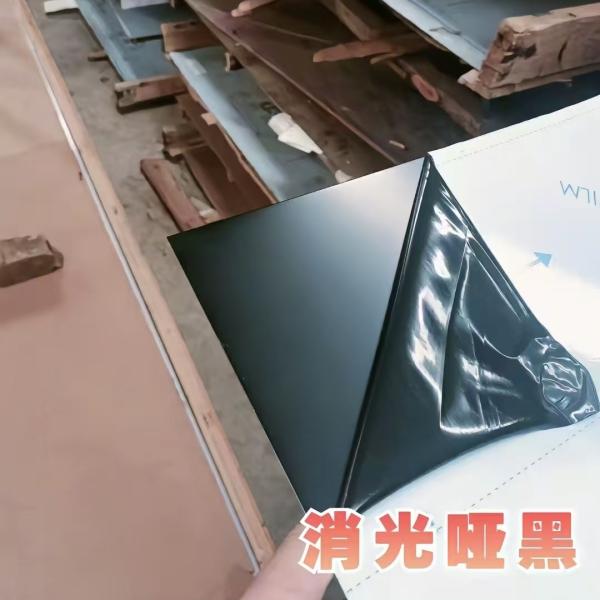

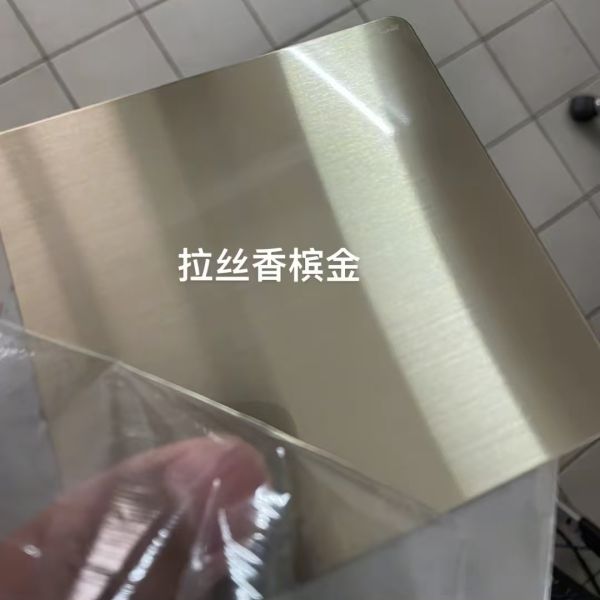

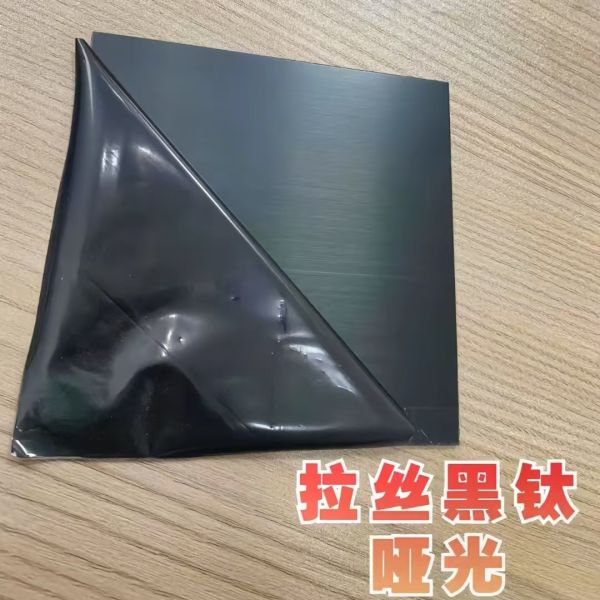

Titanium Black Hairline Stainless Steel Sheet 304 / 1.4301 / SUS304

for Decoration

304 titanium black hairline stainless steel sheet is a

high-performance decorative material that combines excellent

corrosion resistance, aesthetic appeal, and mechanical strength. It

is created by subjecting 304 stainless steel to a specialized

titanium blackening process (forming a durable titanium nitride or

titanium oxide coating on the surface) followed by a hairline

brushing treatment—resulting in a sleek, fine linear texture with a

sophisticated black finish. This sheet is widely favored in

interior/exterior decoration for its ability to elevate spaces with

a modern, minimalist, and high-end look.

1. Corresponding Grades (Equivalent Designations)

304 stainless steel has standardized equivalent grades across major

global regions, ensuring consistency in material performance and

interchangeability for international projects:

| Region/Standard | Grade Designation | Key Note |

|---|

| United States (ASTM) | 304 | The most commonly referenced grade in North America |

| European Union (EN) | 1.4301 | Official designation under European standards, identical to 304 in

composition |

| Japan (JIS) | SUS304 | Japanese industrial standard grade, widely used in Asian

manufacturing |

| China (GB/T) | 06Cr19Ni10 | National standard equivalent, reflecting chemical composition (Cr:

~19%, Ni: ~10%) |

2. Chemical Composition

The chemical composition of 304 (1.4301/SUS304) stainless steel is

strictly regulated, which directly contributes to its corrosion

resistance (especially against rust and oxidation) and structural

stability. The typical composition (per ASTM/EN/JIS standards) is

as follows:

| Element | Content Range (%) | Function |

|---|

| Chromium (Cr) | 18.00 – 20.00 | The core element for corrosion resistance; forms a dense chromium

oxide film on the surface to prevent rust |

| Nickel (Ni) | 8.00 – 10.50 | Enhances ductility, toughness, and resistance to acidic/alkaline

environments; stabilizes the austenitic structure |

| Carbon (C) | ≤ 0.08 | Controls strength and weldability; low carbon content minimizes

carbide precipitation (avoids intergranular corrosion) |

| Manganese (Mn) | ≤ 2.00 | Improves workability and hardenability without compromising

corrosion resistance |

| Silicon (Si) | ≤ 1.00 | Aids in high-temperature stability and manufacturing (e.g.,

casting, rolling) |

| Phosphorus (P) | ≤ 0.045 | Reduces brittleness; kept at low levels to maintain material

integrity |

| Sulfur (S) | ≤ 0.030 | Minimized to prevent corrosion and improve machinability |

3. Mechanical Properties

304 titanium black hairline stainless steel retains the excellent

mechanical properties of base 304 stainless steel, making it

suitable for both decorative and light structural applications. The

typical values (after standard annealing) are:

| Property | Standard Test Method | Typical Value |

|---|

| Tensile Strength (σb) | ASTM A370 / EN 10002-1 | ≥ 515 MPa |

| Yield Strength (σ0.2) | ASTM A370 / EN 10002-1 | ≥ 205 MPa |

| Elongation at Break (δ) | ASTM A370 / EN 10002-1 | ≥ 40% (in 50mm gauge length) |

| Hardness (Brinell) | ASTM E10 / EN ISO 6506-1 | ≤ 201 HB |

| Hardness (Rockwell B) | ASTM E18 / EN ISO 6508-1 | ≤ 92 HRB |

| Impact Toughness (Charpy V-notch) | ASTM A370 / EN 10045-1 | ≥ 27 J (at 20°C, no brittle fracture) |

4. Processing Services

To meet diverse decorative needs, 304 titanium black hairline

stainless steel sheets can be customized through a range of

professional processing services:

- Precision Cutting: Includes laser cutting (for complex shapes,

accuracy ±0.1mm), waterjet cutting (no heat distortion, ideal for

thick sheets), and shearing (for straight-line cutting of large

batches).

- Bending & Forming: Cold bending (to create angles, arcs, or

U-channels) and roll forming (for continuous profiles like

decorative trim), with a minimum bending radius of 1.5× the sheet

thickness (to avoid cracking).

- Edge Processing: Deburring (removes sharp edges for safety), edge

chamfering (creates 45° or rounded edges for aesthetics), and edge

folding (strengthens edges for installation).

- Hole Drilling & Punching: CNC drilling (for precise hole positions)

and punching (for standard holes like mounting holes), suitable for

installation-ready sheets.

- Surface Protection: Laminating (with PE film to prevent scratches

during transportation/installation) and oiling (optional, for extra

corrosion protection in humid environments).

- Custom Finishing: Secondary hairline refinement (adjustable texture

density: 120#–600# grit) or combination finishes (e.g., titanium

black hairline + 局部 mirror polishing for contrast effects).

5. Applications

Thanks to its elegant black hairline appearance, corrosion

resistance, and durability, 304 titanium black hairline stainless

steel is extensively used in decorative fields, including: