| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Front Idler Assembly |

|---|---|

| Brand Name: | YT |

| Model Number: | EC360 |

| Certification: | ISO9001 |

| Place of Origin: | China(Mainland) |

| MOQ: | 1PCS |

| Price: | Negotiable |

| Payment Terms: | L/C,T/T |

| Supply Ability: | 10000 PCS/month |

| Delivery Time: | 7-30 days |

| Packaging Details: | Standard Export Packaging |

| Model NO.: | EC360 |

| Product Name: | Idler or Idler Wheel |

| Finish: | Smooth |

| Hardness Depth: | 8-12mm |

| Origin: | China |

| Process: | Forging/Casting |

| Material: | 40SiMnti |

| Company Info. |

| XIAMEN YINTAI MACHINERY CO., LTD. |

| Verified Supplier |

| View Contact Details |

| Product List |

Volve EC360 Construction Machinery Bulldozer OEM Undercarriage Spare Parts Heat Treatment Front Idler Assembly

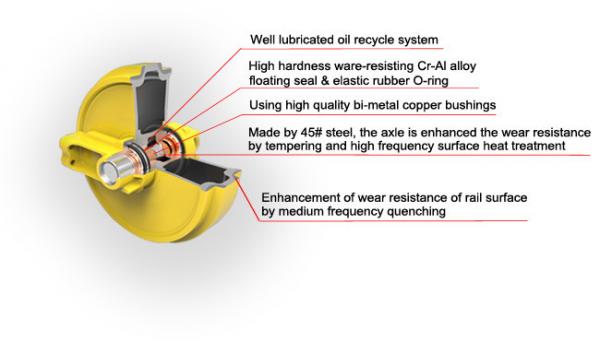

2. Idler Characteristic

50% reduced bearing pressure cuts bearing load drastically, extending component life by 2x or more and eliminating the hassle of frequent replacements; meanwhile, the splined idler-shaft connection secures unrivaled reliability while aligning the idler’s lifespan with other critical undercarriage parts—avoiding uneven wear that shortens system life— and the heavy-duty rock guard serves as a tough barrier against dirt, rubble, and debris, shielding vulnerable components from damage that would lead to costly repairs or replacements.

cutting down on unplanned stoppages that erode profits and disrupt operations—ultimately, these combined advantages prolong the track system’s service life, further reducing overall mining operational costs by lessening downtime and the frequency of part replacements.

4. Production Processes

5. Hot Sale Products

6. Our Advantages

World-class quality

Factory sale directly with reasonable price

35 years' experience in Excavator & Bulldozer spare parts manufacturing

Fast delivery within 30 days after contract established

Professional sales team, quality inspection and report, maritime logistics guidance

After-sale services: video technical support, 24h online support

Are you still troubled by lacking of quality excavator idler? YinTai Parts is one of the professional manufacturers and suppliers of excavator idler in China, who has high quality products for sale. With over 30 years experience and wide expertise, we can assure you the high quality and good performance of our products.

|