| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Ceramic Filling Pump |

|---|---|

| Brand Name: | XQ |

| Model Number: | XQX2 |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 SET |

| Price: | USD 9500-9600 Per Set |

| Payment Terms: | T/T |

| Supply Ability: | 100 Sets per month |

| Delivery Time: | 20 days |

| Packaging Details: | Wooden Packing |

| Application: | Packing machine filling system upgrade of pharmacy industry |

| Pump range: | 0-50ML |

| Pump Material: | SS316L/ high purity ceramic |

| Ceramic part: | Al2O3/ ZrO2/ Sic |

| Air supply: | No need |

| Company Info. |

| Foshan Xiong Qi Intelligent Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

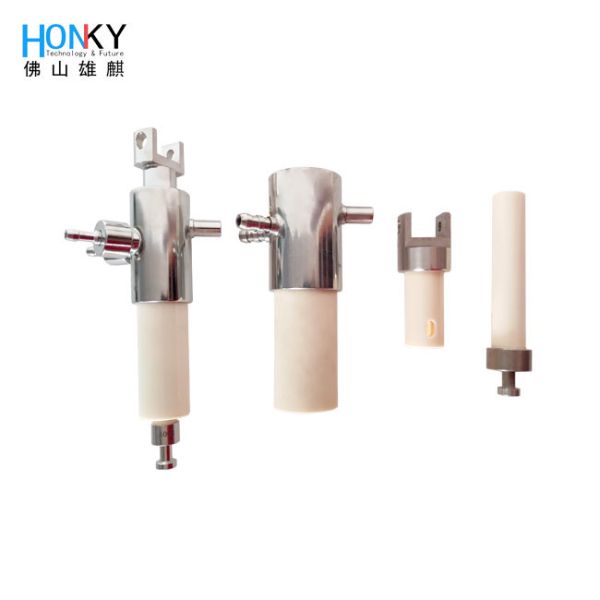

Filling Machine Component Ceramic Piston Filling Pump With High Filling Precision For Pharmacy Liquid Filling

Characteristic of Filling Machine Component Ceramic Piston Filling Pump

1. The metal part of the contact material is made of 316 stainless steel. The pump body has better corrosion resistance. The operation of the pump will not produce trace impurities to pollute the liquid. Removable pump head plunger assembly for cleaning and maintenance.

2. The metering pumps of this series have very high metering accuracy and repetitive consistency, and the accuracy is better than 5,000 of positive and negative.

Ceramic Plunger Pump Series For Processing Industry Make In China – Ceramic plunger pump fittings

Common sizes:0.2~2ml, 0.5~5ml, 1~10ml, 1~12ml, 3~30ml

Material:6-OEM Components Services

Ceramic parts: high purity alumina(Al2O3), zirconia(ZrO2), silicon

carbide(SiC), etc.

Metal part: 316L stainless steel Suitable for ceramic pump

manufacturing and upgrading.

Application of Filling Machine Component Ceramic Piston Filling Pump

1. Suitable for ceramic pump manufacturing and upgrading.

2. It can be used for matching and reforming the filling part of the packaging machine. It is suitable for filling of electrolyte, medicinal liquid, biochemical reagent, chemical liquid, essential oil, essence liquid, emulsion, perfume, nail oil and other medium-low viscosity homogeneous liquid materials.

Technical data of Filling Machine Component Ceramic Piston Filling Pump

| Item No. | -03 | -06 | -09 | -12 | -15 | -18 | -21 | -24 | -27 |

| Pump material | Ceramic parts: high purity alumina(Al2O3), zirconia(ZrO2), silicon carbide(SiC), etc. | ||||||||

| Metal part: 316L stainless steel | |||||||||

| Filling range | 4-80ul | 10-140ul | 20-240ul | 50-700ul | 0.2-1.5ml | 0.2-2.9ml | 0.6-6ml | 1-12ml | 2-25ml |

| Bore diameter | φ4 | φ5 | φ7 | φ10 | φ13 | φ15 | φ22 | φ25 | φ36 |

Product display of Filling Machine Component Ceramic Piston Filling

Pump

Application area

1. ODM and OEM products design;

2. Automatic manufacturing line design;

3. Cosmetic product packing;

4. Pharmaceutical and bio-reagent product packing;

5. Laboratory Liquid dispensing;

6. Lithium Battery Liquid dispensing;

7. Ceramic pump and ceramic pump part design;

8. Other area's material filling;

Q & A

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support.

Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine is a 1-year warranty. And we offer lifetime

after-sale service and technical support.

Q: What are your Installation Services?

A: Installation Services are available with all new machine

purchases. We will provide the user manual and videos to support

installing, debugging, operation of the machine, which will

indicate to you how to use this machine well.

Q: What info will be needed to confirm machine models?

A: 1.The material status.

2. Filling range.

3. Manufacturing speed.

4. Requirements for the production process.

|