| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Industrial Ultrasonic Cleaner |

|---|---|

| Place of Origin: | Guangdong, China |

| Brand Name: | skymen |

| Certification: | FCC/ISO9001:2008, RoHS, ce |

| MOQ: | 1 |

| Price: | Negotiation |

| Power: | 1800W |

| Dimensions: | 710x586x720mm |

| Weight: | 110kg |

| Voltage: | 380V, 220V |

| Tank Capacity: | 100L |

| Tank Dimensions: | 710x586x720mm |

| Timer: | 1~99min, adjustable |

| Heater: | Normal~95degree, adjustable |

| Power Supply: | 220V or 110V |

| Tank Material: | stainless steel SUS304/SUS316L |

| Transducer Number: | 30pcs |

| Cleaning Basket: | SUS304 |

| Ultrasonic Frequency: | 28K/40K Hz |

| Material: | Metal / Coil |

| Fuel: | Electric |

| Company Info. |

| Skymen Technology Corporation Limited |

| Verified Supplier |

| View Contact Details |

| Product List |

Skymen 100l industrial ultrasonic cleaner with CE/ROHS/FCC for various spare parts degreasing/derusting/removing dirt:

Advantages:

Why clean parts with ultrasonic?

Delivering and using clean parts is not always obvious, certainly, no one wants to handle a dirty parts or install it into a critical machine, but, dirty, debris and contaminants can cause problems for manufactures and end users, from the merely frustrating to catastrophic, dirty parts can cause critical components to exceed tolerances and even fail damaging valuable equipment and property while contamination (everything from grease, oil and chemicals to viruses and bacteria) can seriously harm users.

Application of ultrasonic cleaner:

Pictures show:

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

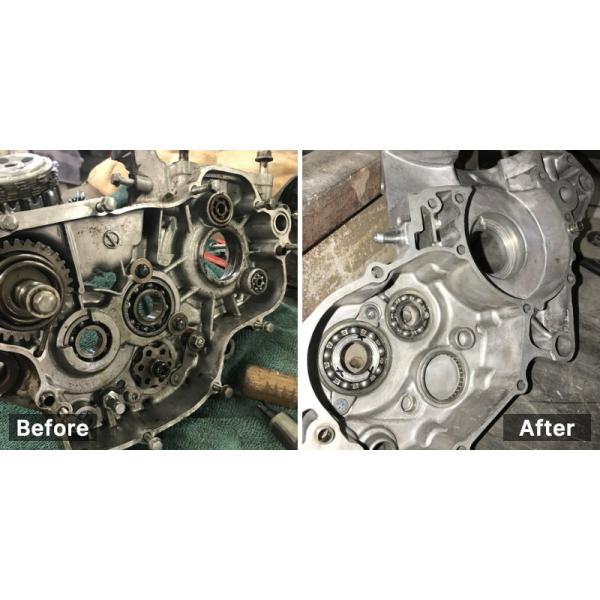

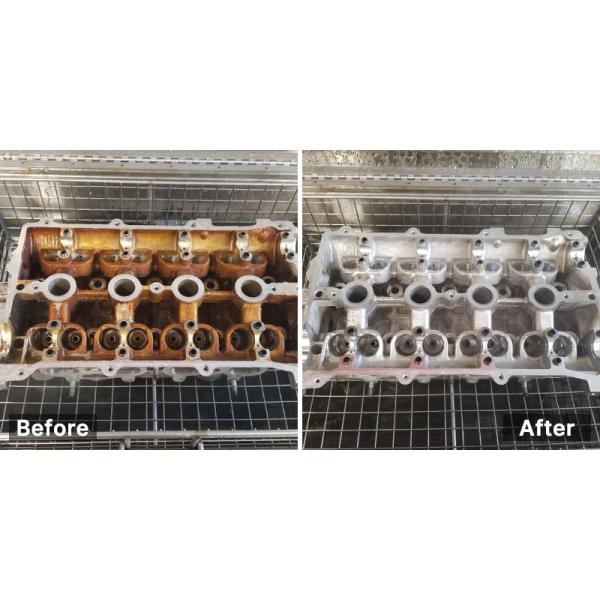

Comparison before and after cleaning:

Quality control:

1. QC and engineers would make strict inspection of the material and production procedure step by step to ensure the quality of every product.

2. salesmen must follow the production process to ensure the machine completely according to the sample.

3. Each unit would be tested at least 4 hours before packed.

After-sale service:

1. Providing 1 year warranty, any technical problem can be asked, any replacement parts will be sent free.

2. After warranty time, technical support is also available for everyone.

Skymen Technology Corporation Limited, which is a leading

manufacturer and national hightech enterprise, was founded in

2007.There are 2 factories of Skymen, one is located in Shenzhen,

closed to HongKong. And the other is located in Shaoguan, Guangdong

province, China.

We have been focusing on R&D of ultrasonic equipment & cleaning

solution for more than 17 years with over 300 employees and plant

size 39,000 square meters. Products include CE, FCC, PSE, KC and

other safety certification, as well as ROHS,PAHS, REACH, SCCP

environmental certification, and passed the factory audit BSCI,

ISO9001 quality management system.

There are more than 200 patents & certificates in total. Our

products range covers industrial ultrasonic cleaner, homeuse

ultrasonic cleaner, commercial ultrasonic cleaner, full-automatic

ultrasonic cleaning machine, ultrasonic transducer rod

series,ultrasonic transducer plate series, tunnel cleaning machine,

large hydrocarbon ultrasonic cleaning equipment with PLC, large

ultrasonic cleaning equipment with vacuum implementation, etc.

Q: How to control the cleaning time?

A: Generally, 3minutes is enough for daily goods clean.

Q: Does ultrasonic cleaner damage the articles?

A: Ultrasonic cleaning is considered safe for most parts; although in some cases it is necessary to observe caution. Although the effect of thousands of implosions per second is very powerful, the cleaning process is safe.

Q: What about after-sale service?

A: our company provides 1 Year warranty. If any technical problem during warranty time, replacement parts will be sent free of charge. After warranty time, technical support is also available for everyone.

Q: What kind of cleaning solution should I use?

A: A large variety of different formulas designed for specific applications. Proper selection is crucial for acceptable cleaning activity and to prevent unwanted reactions with the work piece.

|