| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Steel Structure Garage |

|---|---|

| Brand Name: | QZ RIDGE |

| Model Number: | RS-11181529 |

| Certification: | CE,SGS |

| Place of Origin: | FUJIAN,CHINA |

| MOQ: | 200 square meters |

| Price: | USD 45~55 square meters |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20000 square meters per month |

| Delivery Time: | 45days |

| Packaging Details: | naked |

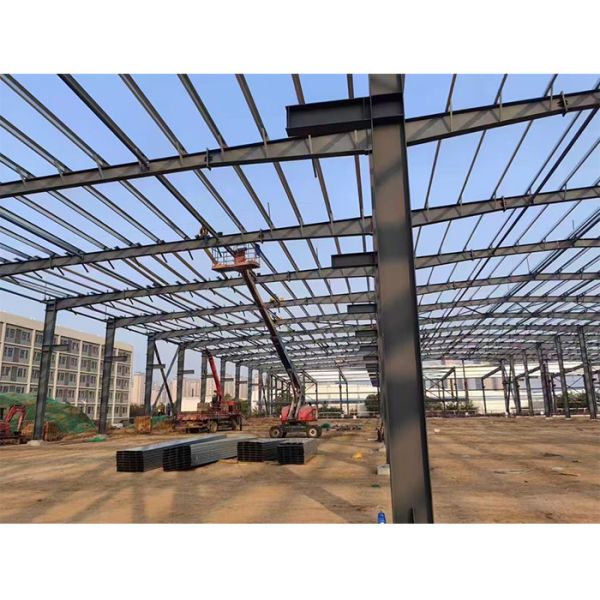

| Product name: | Quick Assembly Prefab Steel Garage Kit Heavy Duty Metal Storage Shed Building |

| Type: | Light |

| Application: | Car garage,Carport |

| Surface treatment: | Hot Dipped Galvanising/Painting |

| Processing Service: | Cutting, Bending, Welding, Fitting, Blasting |

| Material: | Q235/Q345 Steel |

| Structure: | Steel Structure Frame Welded |

| Column and Beam: | Welded H-section |

| Company Info. |

| Quanzhou Ridge Steel Structure Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Prefabricated Garage Steel Structure Building Construction Steel Structure Building

RIDGE Steel: Your Trusted Partner in Steel Structure Solutions

Since 1998, RIDGE Steel Buildings Co. Ltd. has been a leading manufacturer of high-quality steel structures. With over 15 years of exporting experience, we have successfully delivered 1,820 projects totaling 7.6 million square meters. Our two modern factories, spanning 21,000 m² with an annual production capacity of 60,000 tons, ensure we have the capability and expertise to meet your needs.

| Main steel structure (columns and beams) | 1.Steel Q345(S355JR) or Q235(S235JR)H shape |

| 2. Straight cross-section or Variable cross-section | |

| Sub steel structure | 1.Material Q235(S235JR) steel |

| 2.Bolt connections. Anti-rust painted or galvanized | |

| 3. Bracing:X-type or V-type or other type bracing made from angle,round pipe,etc | |

| 4. Purlin:C or Z type:Size from C80~C320,Z120~Z300 | |

| Roof | Sandwich panel(PU/EPS/fiberglass/rook wool) or Colorful steel tile |

| Wall | Sandwich panel(PU/EPS/fiberglass/rook wool) or Colorful steel tile |

| Doors | Steel rolling shutter or others |

| Windows | Alu. Alloy window,or others |

| Edge Cover | Steel sheet 0.5mm thickness |

| Bolts | M24,M22,M16 embedded bolts,intensive bolts,galvanized ordinary bolts,high-strength bolts,etc |

| Others options | Skylight panel,Roof ventilator,Down pipe,Galvanized,Crane,sanitary Products |

| Foundation | Cement and steel foundation bolts |

Our Integrated Process

Why Choose Steel Structures?

Our Product System

——QUOTE INFORMATION——

Could you tell me your requirement for your steel structure

project?

Basic design requirements and design Load,

1. Project site location;

2. Overall dimension (length*width*eave height in meters);

3. Mezzanine or not? How many kgs of load per square meter on

mezzanine?;4. Single-layer steel sheet wall or sandwich panel wall;

5. Snow load if applicable;

6. Wind speed/load;

7. Interior column allowed or not;

8. Overhead crane needed or not, capacity?;

9. Any other particular requirements?

Building Purpose:

we will recommend the best design for the purpose of the building.

A. Warehouse/Storage

B. Factory

C. Agriculture Barn

D. Retail Store

E. Repair/Mechanic Shop

F. Office Space

G. Medical Warehouse

H. Animal Farm (please confirm what kind of animal)

We'll provide the detailed installation drawing, supervisors guiding installation is available. We can do turnkey job for some kind of projects.

|