| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Ceramic Ball Bearings |

|---|---|

| Brand Name: | CSQ |

| Model Number: | 6201ce |

| Certification: | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Place of Origin: | Beijing, China |

| MOQ: | 20-50 pcs |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 2000pcs per months |

| Delivery Time: | 25-45 work days(negotiable) |

| Packaging Details: | Foam+carton box |

| Material: | ZrO2 |

| Bearing Type: | Full Ball Bearing |

| Percision: | P6/ABEC3 to P4/ABEC7 |

| Characteristic: | Long-lasting life, Low noise, High precision |

| Application: | Skateboard, roller skate, water pump |

| Clearance: | C0-C5 |

| Number of Row: | Single row |

| Structure: | Deep groove |

| Inner Diameter: | 12mm |

| Out Diameter: | 32mm |

| Width: | 10mm |

| Company Info. |

| Beijing Zhongxing Shiqiang CERAMIC BEARING Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Product Introduction: 6201 Full Zirconia Ceramic Bearing (with PTFE Cage)

Product Overview

The 6201 Full Zirconia Ceramic Bearing is a high-performance deep groove ball bearing manufactured to the international standard 6201 dimensions. It features inner ring, outer ring, and rolling elements made from high-purity Zirconia Ceramic, combined with a PTFE cage.

This unique material combination makes it the ultimate solution for extreme operating conditions involving corrosion, dry-running, high speeds, and electrical insulation, effectively solving the common failures of traditional steel bearings related to corrosion, electrical erosion, and lubricant contamination.

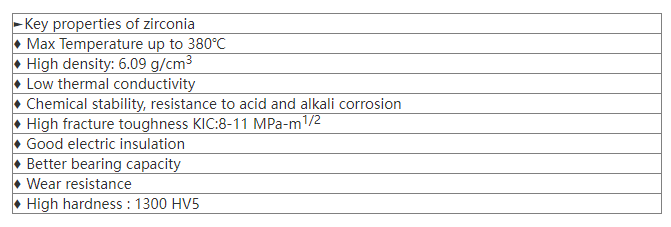

Material and Properties

1.Rings & Balls: High-Purity Zirconia Ceramic

2.Cage: PTFE

Synergistic Effect: The combination of the PTFE cage with Zirconia balls results in very low friction and wear, outperforming metal-caged bearings significantly in dry or boundary lubrication states.

Working Principle

As a deep groove ball bearing, it supports shafts and reduces rotational friction via rolling contact. Its special materials introduce unique operational mechanisms:

Parameter Table

| Parameter | Description |

| Material | Ceramic: ZrO2 |

| Corrosion resistance | Excellent |

| Friction | Lower than steel |

| Wear resistance | Excellent |

| Temperature resistance | High |

| Strength | Higher than steel |

| Durability | Excellent |

| Weight | Lighter than steel |

| Precision | High |

| Biocompatibility | Some ceramic materials are biocompatible |

Application Scenarios

This bearing is the ideal choice for the following high-end and demanding applications:

Why Choose Us

1.Professional team

Our company logo is ZXSQ and CSQ, and possesses eleven invention patents for utility models. The company now has a high-quality professional team consisting of dozens of members, to provide you with high-quality and perfect service, according to customer requirements to order a variety of bearing products.

Since the year of 1982 we have accumulated abundant experience in the production over the past more than 40 years, devoting ourselves whole -heartedly to the research and development of ceramic bearing material, our processing technique and improvement of our equipments.

Having undergone several evolution and transformation, our company has now become the leading enterprise in China domestic market in the fields of ceramic bearing and ceramic material products.

2.Strength factory

At present, we have a fully automatic grinding and assembling production line for ceramic bearings, with an annual output of 3 million sets of 608-2PS, 608-2RS and other specifications of P5 and P4 precision levels.

Firing equipment and technology leading in the industry. Our company has the most high-end equipment in the field of domestic industrial ceramics production, in addition to the hot isostatic sintering furnace (HIP) imported from ABB Sweden. Our company also has other production equipment, the product firing temperature has been raised to more than 2000℃.

3.Master raw material production technology

We cooperate with raw material suppliers to ensure product quality and profit stability without being affected by international raw material price fluctuations. It is not suppressed by foreign enterprises by raising the price of raw materials. At the same time with raw material production technology, when necessary, we can produce raw materials by ourselves.

FQA

Q:Who are we?

A:We are a factory in Beijing, China. We have been producing and selling ceramic bearings for more than 40 years. We have established friendly cooperative relations with many domestic and foreign companies.

Q:How can we guarantee quality?

A:We always produce samples before mass production, and produce in strict accordance with customer requirements and production regulations. After the completion of production, we will use inspection equipment to carry out precise inspection of products, and our packaging adopts the double insurance of foam and carton, to strictly ensure the quality of products.

Q:What can you buy from us?

A:Ceramic deep groove ball bearings, ceramic angular contact ball bearings, hybrid ceramic ball bearings, ceramic linear bearings, etc and all kinds of ceramic balls.

Q:Why should you buy from us not from other suppliers?

A:We are an industry and trade integrated company, we have three factories, with today's production and inspection equipment, can provide better delivery dates and product quality.

Q:What service can we provide?

A:We will provide high quality products and customized services, which can be fully customized according to user needs. We can provide samples for customer's confirmation.

Welcome your enquiry

We supply bearings, high quality products, if you need to buy or consult the price of bearings, please contact us. We are a set of bearing research and development, production, sales, service in one of the professional bearing company, providing bearing products and related technical services. We choose high quality raw materials, carefully do each set of bearings.

We adhere to customer demand as the guidance, and strive to provide customers with quality products and after-sales service, create value for customers, do customers partner. Welcome to discuss the cooperation!

|