| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Skived Fin Heat Sink |

|---|---|

| Brand Name: | Sunmoral |

| Model Number: | 1 |

| Place of Origin: | China |

| Process: | Skiving |

| Color: | Black |

| Base Size: | 10-200mm |

| Surface Treatment: | Anodizing |

| Features: | Lightweight, High Thermal Conductivity, Customizable |

| Material: | Aluminum |

| Application: | Electronic Devices |

| Fin Density: | 100-2000 Fins/inch |

| Company Info. |

| Sunmoral Thermal Control Systems Co., LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

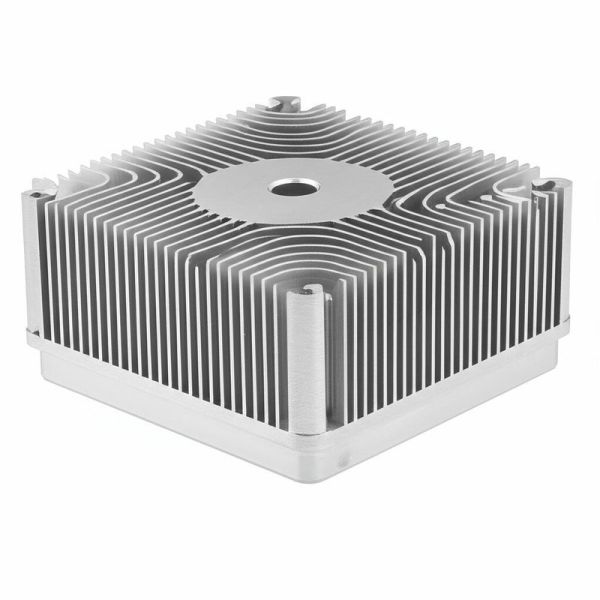

The Skived Fin Heat Sink is an advanced thermal management solution designed to meet the rigorous demands of modern electronic devices. Utilizing the innovative skiving process, this heat sink offers exceptional performance by maximizing heat dissipation efficiency while maintaining a compact and lightweight design. With a fin density ranging from 100 to 2000 fins per inch, the Skived Fin Heat Sink provides unparalleled surface area for heat exchange, making it an ideal choice for applications that require precise and effective thermal control.

One of the standout features of this product is its highly customizable base size, which ranges from 10mm to 200mm. This versatility allows the Skived Fin Heat Sink to be tailored to fit a wide variety of electronic devices, from small-scale components to larger industrial equipment. The skiving process used to manufacture these heat sinks involves the precise cutting and bending of metal sheets to form thin, closely spaced fins that are integral to the base. This method not only ensures excellent thermal conductivity between the fins and the base but also results in a robust and durable structure capable of withstanding harsh operating conditions.

The surface of the Skived Fin Heat Sink undergoes anodizing treatment, which significantly enhances its corrosion resistance and surface hardness. Anodizing also improves the emissivity of the heat sink, thereby boosting its ability to radiate heat away from the electronic components it protects. This surface treatment is particularly beneficial in industrial environments where heat sinks are exposed to moisture, chemicals, and other potentially damaging elements.

In terms of application, the Skived Fin Heat Sink is primarily designed for electronic devices that generate substantial heat during operation. It is widely utilized in various sectors, including telecommunications, computing, power electronics, and automotive electronics. Its efficient heat dissipation capability ensures that electronic components maintain optimal operating temperatures, which in turn enhances their reliability, performance, and longevity.

The product is also highly regarded as a Fin Type Heat Exchanger. Its dense fin arrangement facilitates superior air flow and heat transfer, enabling it to function effectively even in compact spaces where traditional heat exchangers may fall short. This makes the Skived Fin Heat Sink an excellent choice for integration into complex systems where space is at a premium.

Moreover, the Skived Fin Heat Sink can be incorporated into Fin And Tube Heat Exchanger configurations, further expanding its versatility in industrial heat management applications. By combining the skived fins with tubing systems, the heat sink can efficiently transfer heat from fluids or gases, making it suitable for use in HVAC systems, refrigeration units, and other industrial processes requiring reliable heat exchange.

As an Industrial Heat Sink, the Skived Fin Heat Sink stands out for its exceptional thermal performance, durability, and adaptability. Its advanced manufacturing process, high fin density, customizable base size, and superior surface treatment collectively contribute to a product that meets the demanding needs of modern electronic cooling solutions. Whether used in consumer electronics, industrial machinery, or specialized equipment, this heat sink delivers consistent and efficient thermal management, ensuring devices operate safely and efficiently.

In summary, the Skived Fin Heat Sink is a cutting-edge thermal solution that offers high fin density between 100 and 2000 fins per inch, customizable base sizes from 10mm to 200mm, and a durable anodized surface. Its application in electronic devices, combined with its role as a Fin Type Heat Exchanger and compatibility with Fin And Tube Heat Exchanger systems, makes it a versatile and reliable choice in the field of industrial heat sinks. With this product, engineers and designers can achieve superior thermal performance, prolong device lifespan, and enhance overall system efficiency.

| Fin Density | 100-2000 Fins/inch |

| Features | Lightweight, High Thermal Conductivity, Customizable |

| Color | Black |

| Application | Electronic Devices |

| Process | Skiving |

| Base Size | 10-200mm |

| Surface Treatment | Anodizing |

| Material | Aluminum |

The Sunmoral Skived Fin Heat Sink, Model Number 1, originating from China, is an advanced thermal management solution designed to meet the demanding requirements of various industrial and commercial applications. Its lightweight aluminum construction combined with high thermal conductivity ensures efficient heat dissipation, making it ideal for use in environments where temperature control is critical.

One of the primary application occasions for the Sunmoral Skived Fin Heat Sink is in industrial heat sink systems. These heat sinks are essential components in machinery and equipment where excessive heat can impair performance or cause damage. Thanks to its customizable base size ranging from 10mm to 200mm and anodized black surface treatment, this heat sink offers both versatility and durability, allowing it to be tailored to specific industrial needs while providing excellent corrosion resistance.

The product is particularly effective when integrated with heat exchanger fin tubes, where its skived fins enhance the surface area for heat transfer. This makes it suitable for heat exchanger applications in HVAC systems, power electronics, and automotive cooling systems. The precise cold forging heat sink manufacturing process used by Sunmoral ensures tight thermal contact and superior structural integrity, which translates to improved heat exchange efficiency and longer service life.

In addition to industrial settings, the Sunmoral Skived Fin Heat Sink is also widely employed in electronics cooling scenarios, such as in LED lighting, power supplies, and telecommunications equipment. Its lightweight nature simplifies installation and reduces the overall weight of the device, which is a significant advantage for applications requiring compact and efficient thermal solutions.

Moreover, the ability to customize the fin dimensions and base size allows engineers to optimize the heat sink for specific thermal loads and spatial constraints. This flexibility ensures that the Sunmoral Skived Fin Heat Sink can be effectively utilized in a broad spectrum of scenarios, from high-power industrial machinery to delicate electronic devices, providing reliable temperature control and enhanced operational stability.

Sunmoral offers comprehensive product customization services for our Skived Fin Heat Sink, model number 1, made in China. Our heat sinks feature a sleek black color and are crafted from high-quality aluminum, ensuring lightweight construction and high thermal conductivity. The base size of the heat sink can be customized from 10mm to 200mm to suit your specific requirements.

We provide a wide range of fin densities, from 100 to 2000 fins per inch, allowing precise control over thermal performance. Our skived fin technology is ideal for Fin And Tube Heat Exchanger applications, delivering efficient heat dissipation and enhanced durability. Whether you need a Heat Exchanger Fin Tube or a Fin Type Heat Exchanger, Sunmoral’s customizable options can be tailored to meet your unique design and performance needs.

With Sunmoral’s expertise in aluminum heat sink manufacturing, you can expect superior quality, optimized thermal management, and flexibility in design. Contact us to customize your Skived Fin Heat Sink and improve your system’s cooling efficiency with our advanced Fin And Tube Heat Exchanger solutions.

|