| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Paper Cup Fan |

|---|---|

| Brand Name: | XHY |

| Model Number: | XHY |

| Certification: | FSC |

| Place of Origin: | CHINA |

| MOQ: | 2 TON |

| Price: | Depending on your quantity and design |

| Payment Terms: | T/T |

| Supply Ability: | 2000 Tons Per Month |

| Delivery Time: | 15-30 days |

| Packaging Details: | 25KG/Pack 60×60×50Cm |

| Pulp Style: | Virgin |

| Feature: | Greaseproof/Heat Insulation/Waterproof |

| Eco-friendly: | Yes |

| Shipping: | Via Sea Transport |

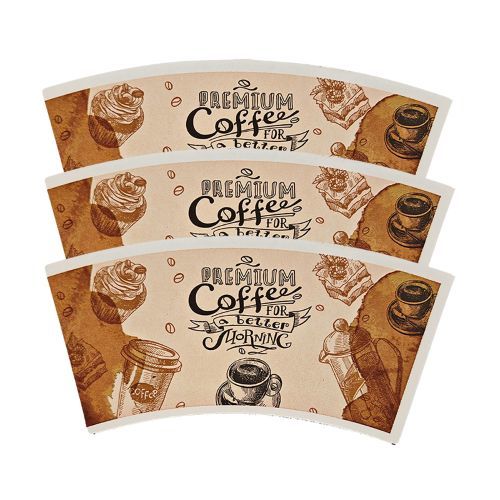

| Printing Type: | Offect Printing/Flexographic Printing |

| Paper Weight: | 150-350 gsm |

| Key Words: | Paper Cup Fans |

| Printing Logo: | 1-7 colors |

| Use For Packing: | Customized Packing Way Is Acceptable |

| Size: | Various Sizes Available |

| Design: | Depending on your requires |

| Branding: | Can Be Branded With Logo or Word |

| Material: | 100% Virgin Wood Pulp |

| Coating: | PE or PLA coated |

| Characteristic: | Food Grade/Resuable |

| Package: | Packed In Outer Carton |

| Condensation Control: | Yes |

| Dimension: | Customized |

| Company Info. |

| Wuhan Xinhuayuan Environmental Science and Technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

| Brand Name | XHY |

|---|---|

| Certification | FSC |

| PE/PLA Weight | 9-26gsm |

| Paper Weight | 150-350gsm |

| Core Dia | 3 inch, 6 inch |

| Material | 100% Wood Pulp |

| Usage | Paper Cups, Hot Drinks, Cold Beverages etc |

| Feature | Heat Insulation, Greaseproof, Waterproof |

| Color | 1-7 Colors |

| Size | 2.5oz-32oz |

The Manufacturing Process of Paper Cup Fan Blanks

Raw Material Preparation: Large rolls of paper (paperboard) are used. This paper is often coated with polyethylene (PE) or polylactic acid (PLA) to make it waterproof.

Printing (Optional): If the cups require patterns or logos, this is the stage where the paper web is printed using flexographic or offset printing presses.

Lamination (If applicable): For cups requiring extra insulation or a different internal/external finish, an additional layer of film might be laminated to the paper.

Die-Cutting: This is the core step for creating the "fan" shape. The large roll of printed and coated paper is fed into a die-cutting machine. A specialized steel mold (die), shaped like a fan or trapezoid, stamps out the individual fan blanks from the paper web at high speed.

Waste Stripping: The leftover paper skeleton (the "matrix") from the die-cutting process is rewound and discarded for recycling.

Counting and Stacking: The correctly cut fan blanks are automatically counted and stacked into neat piles.

Packaging and Shipping: The stacks of fan blanks are packaged in cartons or shrink-wrapped to protect them from moisture and damage. They are then shipped to paper cup manufacturers.

A: Yes, our professional designer can make design for free according to your requirements (including size, color, dimension, quantity etc).

A: We provide free samples for you checking the printing and quality of the paper cups, but the express cost need to be collected.

A: About 10-15 days.

A: Please tell us what's the size, paper material and quantity do you like. And send us your design. We will give you a competitive price.

|