| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Stainless Steel Sheet |

|---|---|

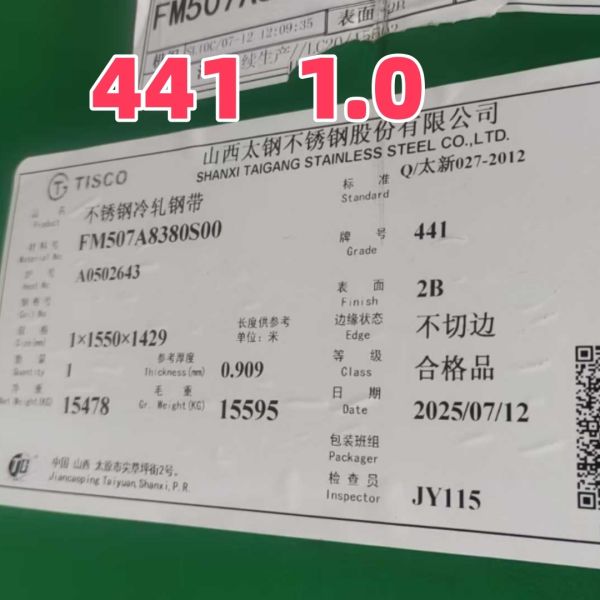

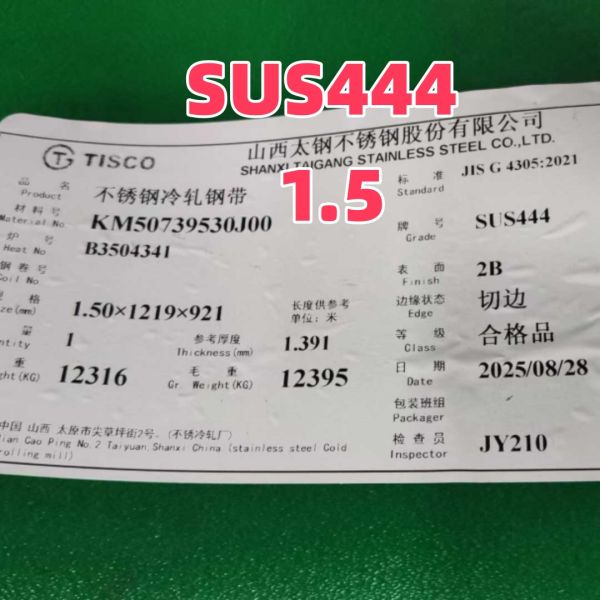

| Brand Name: | ZPSS TISCO BAO STEEL |

| Model Number: | 444 |

| Certification: | SGS ISO MTC |

| Place of Origin: | China |

| MOQ: | 500KGS |

| Price: | 1.85-2.45 USD/KG |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50000KGS |

| Delivery Time: | 14 Days |

| Packaging Details: | Export Packing |

| Material: | SUS444 |

| Metal type: | Stainless Steel |

| Color: | Customized 2B 2D |

| Shape: | Flat Sheet |

| Thickness: | 1-3mm |

| Width: | 1000-2000mm |

| Length: | 2000-6000mm |

| Company Info. |

| JIANGSU MITTEL STEEL INDUSTRIAL LIMITED |

| Verified Supplier |

| View Contact Details |

| Product List |

| Product | Stainless Steel Sheet and Coil |

| Steel Grade | 200 Series: 201,202 300 Series: 301,304,304L,316,316L,316Ti,309,310,317,321 400 Series: 409,410,420,430,436,444,441,440c Duplex Steel: 904L,2205,2507,2101,2520,2304 |

| Thickness | 0.1mm-16mm |

| Width | 10mm-2000mm |

| Manufacturing Method | Cold Rolled, Hot Rolled |

| Surface | No.1, 2D, 2B, BA, 8K mirror, No.4, Hairline, Sandblasting |

| Edges | Mill Edges, Silt Edges |

| Surface Treatment | Corrugated, Perforated, Embossed, Etched, Water Rippled |

| MOQ | 1 Ton |

| Free Samples | Available |

| Per Coil Weight | 1-8 tons |

| Package | Seaworthy packing with wooden pallets and waterproof paper |

| Leading time | Usually 10-15 days, if in stock 1-3 days. |

| Payment terms | T/T 30% for deposit. 70% balance before shipment |

| Delivery Terms | FOB/CIF/CFR/EXW |

| Raw Material Source | Tisco, Baosteel, Qingshan or as Your Request |

Food processing, brewery and wine making equipment, hot-water tanks, heat-exchanger tubing and automotive components

Type 444 is a low carbon, low nitrogen, ferritic stainless steel that provides pitting and crevice corrosion resistance superior to most ferritic stainless steels. Applications requiring superior corrosion resistance and resistance to chloride stress corrosion cracking are ideal for this alloy.

Carbon: 0.025 max

Manganese: 1.00 max

Silicon: 0.60

Chromium: 17.50-19.50

Nickel: 01.00 max

Molybdenum: 1. 75-2.50

Titanium+ Columbium : 0.20 + 4x (Carbon+ Nitrogen) min-0.80 max

Phosphorus: 0.040 max

Sulfur: 0.030 max

Iron: Balance

Density: 0.28 lbs/in3 7.75 g/cm3

Electrical Resistivity: microhm-in (microhm-cm):

68 ° F (20 ° C): 22.50 (57)

Specific Heat: BTU/lbl° F (kJ/kg•K):

32 - 212 ° F (0 - 100 ° C): 0.102 (0.427)

Thermal Conductivity: BTU/hr/ft2/ft/° F (W/m•K)

At 212 °F (100 °C): 15.5 (26.8)

Mean Coefficient of Thermal Expansion: in/inl° F (µm/m•K):

32 - 212 ° F (0 - 100 °C): 6.1 x 10-s (11.0)

Modulus of Elasticity: ksi (MPa)

29 x 103 (200 x 103) in tension

Magnetic Permeability: Magnetic

Melting Range: 2700 - 2790 ° F (1482 - 1532 °C)

Coil - Strip, Foil, Ribbon Wire - Profile, Round, Flat, Square

Ultimate Tensile Strength: 60 KSI min (414 MPa min)

Yield Strength (0.2% offset): 40 KSI min (276 MPa min)

Elongation: 22% min

Hardness: Rb 90 max

Type 444 can be rolled to various tempers. Consult Ulbrich Technical Services if temper rolled product is required.

Refer to NACE (National Association of Corrosion Engineers) for recommendations.

# 1 - Hot rolled annealed and descaled. It is available in strip,

foil and ribbon. It is used for applications where a smooth

decorative finish is not required.

# 2D - Dull finish produced by cold rolling, annealing and

descaling. Used for deep drawn parts and those parts that need to

retain lubricants in the forming process. # 2B - Smooth finish

produced by cold rolling, annealing and descaling. A light cold

rolling pass is added after anneal with polished rolls giving it a

brighter finish than 2D.

#BA- Bright annealed cold rolled and bright annealed

#CBA- Course bright annealed cold rolled matte finish and bright

anneal

#2 - Cold Rolled

# 2BA- Smooth finish produced by cold rolling and bright annealing.

A light pass using highly polished rolls produces a glossy finish.

A 2BA finish may be used for lightly formed applications where a

glossy finish is desired in the formed part. Polished - Various

grit finish for specific polish finished requirements.

Type 444 provides excellent formability and can be readily deep drawn and spin formed. Stretch forming, however, is limited in application for this alloy.

Type 444 is non-heat treatable.

Q: What are the details of your after sales service?

A:1) We provide the necessary technical support to all of our

customers, such as material performance and heat treatment data

advice.

2) We provide the appropriate steel material technical parameters

for customers in Germany, The USA, Japan, Britain, and other

countries.

Q: How could I get a sample?

A: Before we received the first order, please afford the sample

cost and express fee. We will return the sample cost back to you

within your first order.

|