| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Underground Sewage Treatment Equipment |

|---|---|

| Brand Name: | SH |

| Model Number: | Carbon Steel Underground Integrated Equipment |

| Certification: | CE; ISO14001; ISO19001;ISO45001;EAC |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 2000 sets / year |

| Delivery Time: | 5 work days |

| Packaging Details: | OEM |

| Material of Tank Body: | Carbon Steel Q235 / Q345 |

| Anti-corrosion Coating: | Epoxy resin / Polyurethane / FRP coating |

| Installation Type: | Underground / Semi-underground |

| Operating Temperature: | 5 – 45 ℃ |

| Control Mode: | Automatic / Semi-automatic |

| Sludge Discharge: | Manual / Automatic with pump |

| Company Info. |

| Jiangsu Sanhe Environmental Protection Group Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

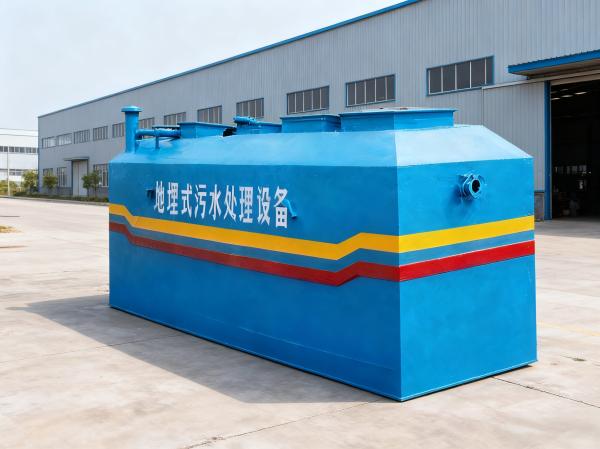

Carbon Steel Underground Integrated Equipment

Product Overview

The Carbon Steel Underground Integrated Equipment is a compact and

efficient solution for wastewater and reclaimed water treatment. It

is installed below ground level, saving surface space and providing

a clean, noise-free environment. The equipment integrates multiple

treatment processes such as sedimentation, biological treatment,

filtration, and disinfection within a sealed structure.

Constructed with high-strength carbon steel and anti-corrosion

coatings, it ensures long-term durability and stable operation even

under complex underground conditions.

Working Principle

Raw wastewater enters the equipment through the inlet pipe and sequentially passes through different internal chambers such as the sedimentation tank, biological treatment zone, and filtration section.

Suspended solids are first removed by sedimentation.

The biological section decomposes organic matter through aerobic or anaerobic reactions.

The filtration and disinfection stages further purify and sterilize

the water.

The treated effluent meets discharge or reuse standards, while

sludge is periodically removed through the sludge discharge outlet.

Main Components

nlet Chamber: Guides raw wastewater into the system evenly.

Sedimentation Section: Removes suspended solids through gravity settling.

Biological Treatment Zone: Performs aerobic or anaerobic treatment to remove organic contaminants.

Filtration Unit: Further polishes the treated water to improve clarity.

Disinfection Chamber: Ensures the effluent meets hygienic discharge or reuse standards.

Sludge Storage and Discharge System: Collects and removes accumulated sludge.

Ventilation System: Prevents accumulation of harmful gases in the underground chamber.

Carbon Steel Shell: Fully welded, coated with epoxy or polyurethane for corrosion resistance.

Access Cover and Maintenance Port: Allow convenient inspection and maintenance.

Control Cabinet: Integrates electrical control, automation, and monitoring functions.

Underground installation with minimal surface occupation

High-strength carbon steel construction with anti-corrosion coating

Integrated multi-process treatment design (sedimentation, bio, filtration, disinfection)

Modular and customizable configuration

Easy maintenance and long lifespan

Stable operation with low energy consumption

Suitable for fully automatic or semi-automatic control

Municipal domestic sewage treatment

Residential and office building wastewater systems

Industrial wastewater pretreatment or reuse

Hotels, hospitals, and schools wastewater treatment

Rural or decentralized sewage treatment projects

Optional Configurations

Air blower and aeration system (for aerobic treatment)

Automatic sludge discharge valve and pump

Remote monitoring and data recording system

Internal UV or ozone disinfection unit

Activated carbon or multi-media filtration module

Backup power and overload protection unit

Anti-corrosion coating upgrade (epoxy, polyurethane, or FRP)

|