| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | HIWIN Linear Guide |

|---|---|

| Brand Name: | HIWIN |

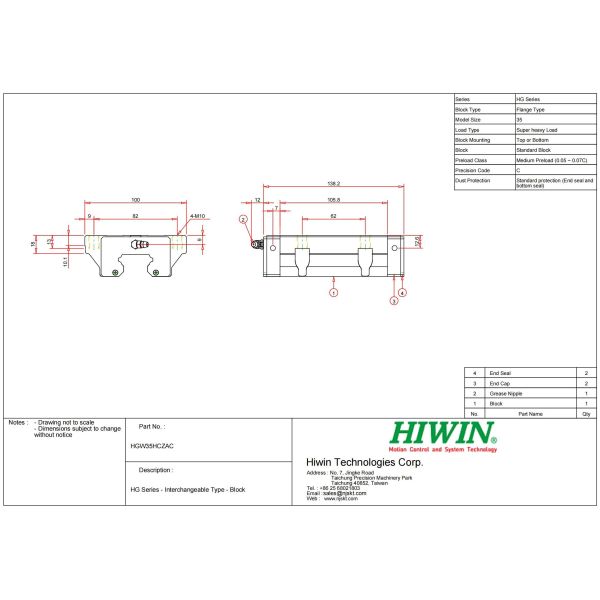

| Model Number: | HGW35HC |

| Certification: | DE1924083895474 |

| Place of Origin: | CHINA TAIWAN |

| MOQ: | 10 |

| Price: | 1-100 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,Western Union |

| Supply Ability: | 100000 pcs / per month |

| Delivery Time: | 1-7 work days |

| Packaging Details: | Small or with carton box, Bulk order with Wooden box |

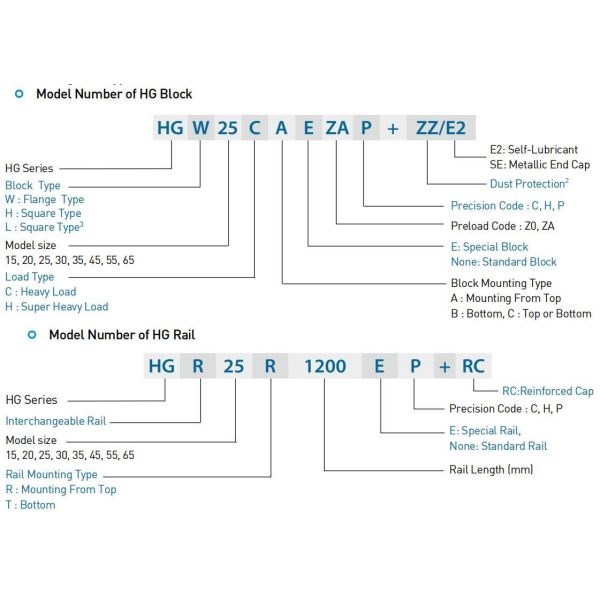

| Series: | HG |

| Model Size(mm): | 35mm |

| No. of Blocks per Rail: | 1 |

| Rail Mounting Type: | R- Mounting From Top |

| Rail Length(mm): | Max 4000mm |

| Preload Class: | Z0- Light Preload , ZA- Medium Preload, ZB-Heavy Preload |

| Material: | SNCM220 Carbon Steel |

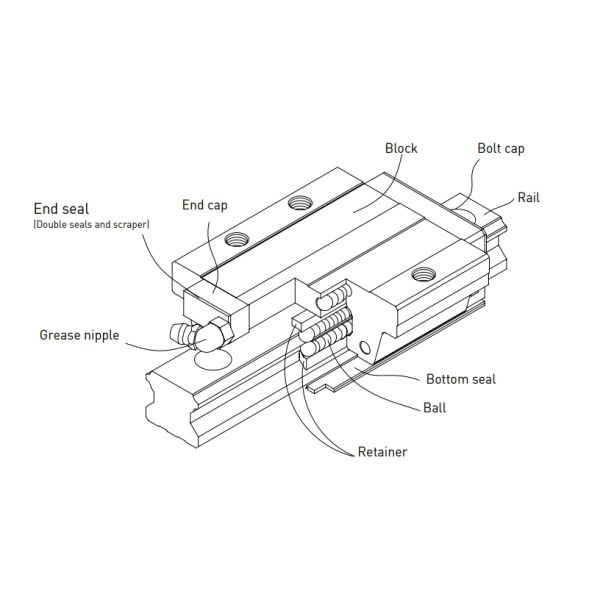

| Dust Protection: | SS-standard |

| Y -Symmetrical (E1=E2) First hole dimension: | Y= Symmetrical (E1=E2) |

| Installation: | Easy |

| Application: | NC lathe, EDM, measuring equipment |

| Smoothness: | Smooth |

| Company Info. |

| NanJing TranzBrillix Linear Motion Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Engineered to withstand the most demanding machining environments, the HIWIN HGW35HC Linear Guideway delivers uncompromising rigidity and precision for high-performance machining centers. This heavy-rail solution incorporates HIWIN's decades of metalcutting expertise to provide the ultimate foundation for aggressive milling, deep-hole drilling, and precision boring operations.

The HGW35HC features HIWIN's innovative harmonic load distribution system, specifically developed to absorb cutting vibrations during heavy material removal. Its monolithic rail construction provides exceptional torsional stiffness, maintaining accuracy during complex contouring operations. The guideway's thermal compensation technology automatically adjusts to heat variations during continuous machining cycles, ensuring consistent tolerances throughout production runs.

Designed for bridge-type and gantry machining centers, this heavy rail incorporates HIWIN's self-cleaning groove technology, actively preventing chip accumulation in high-volume production. The hardened contact surfaces and optimized recirculation paths ensure smooth motion under maximum table loads, while integrated lubrication channels provide continuous protection during extended cutting operations.

Trusted by premium machine tool builders worldwide, the HGW35HC represents HIWIN's commitment to machining excellence – where industrial-strength performance meets micron-level precision in today's most challenging manufacturing applications.

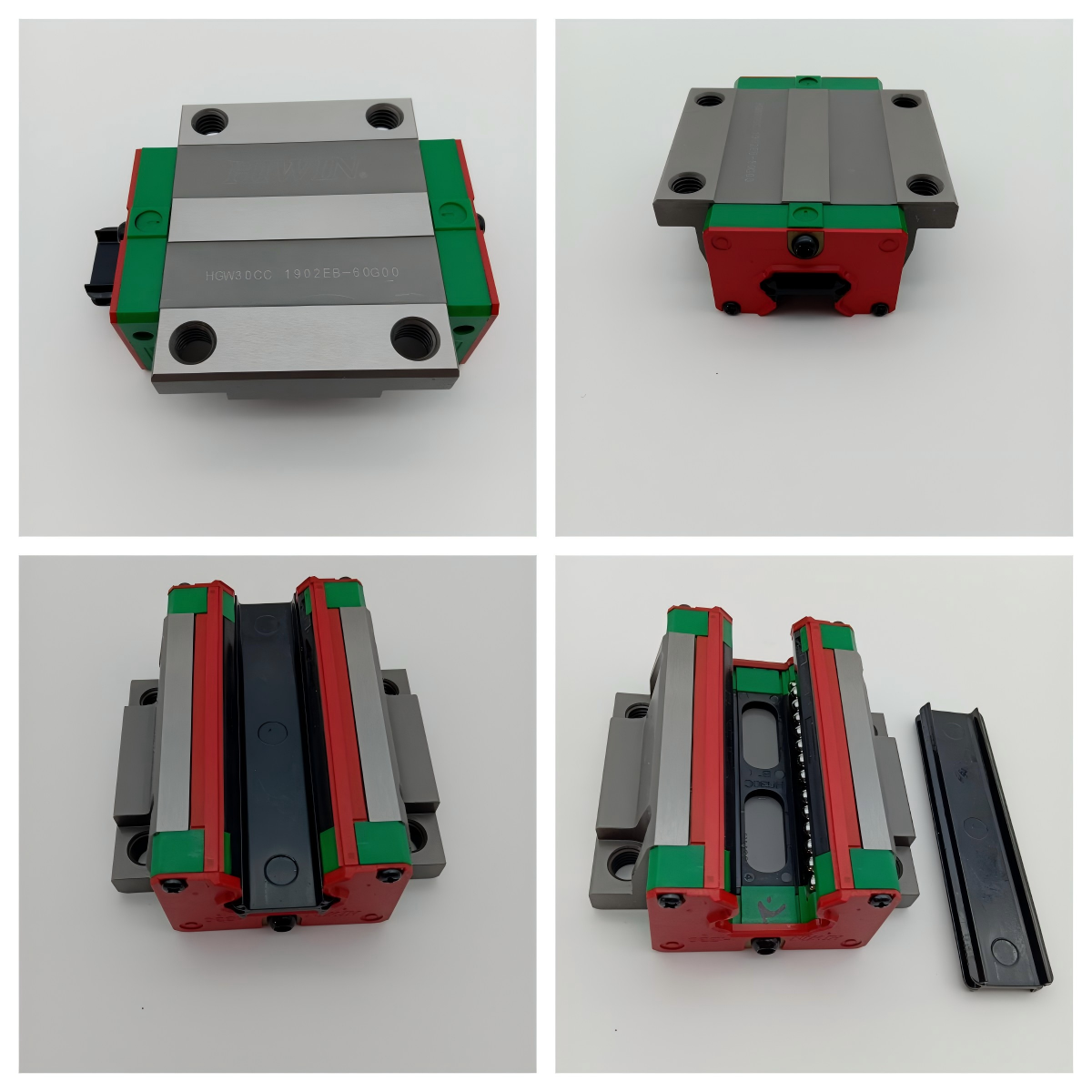

⑥Actual product photo

|